Driving mechanism motion direction conversion device and method

A technology of motion direction and driving mechanism, which is applied in the direction of power control mechanism, wing fan control mechanism, wing fan suspension device, etc., can solve the problem that extrusion force cannot produce the direction force of the Sierra, cannot satisfy customers, and Sierra Caton and other problems, to achieve the effect of solving the door closed tightly, the structure is small and reasonable, and the degree of wear and tear is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

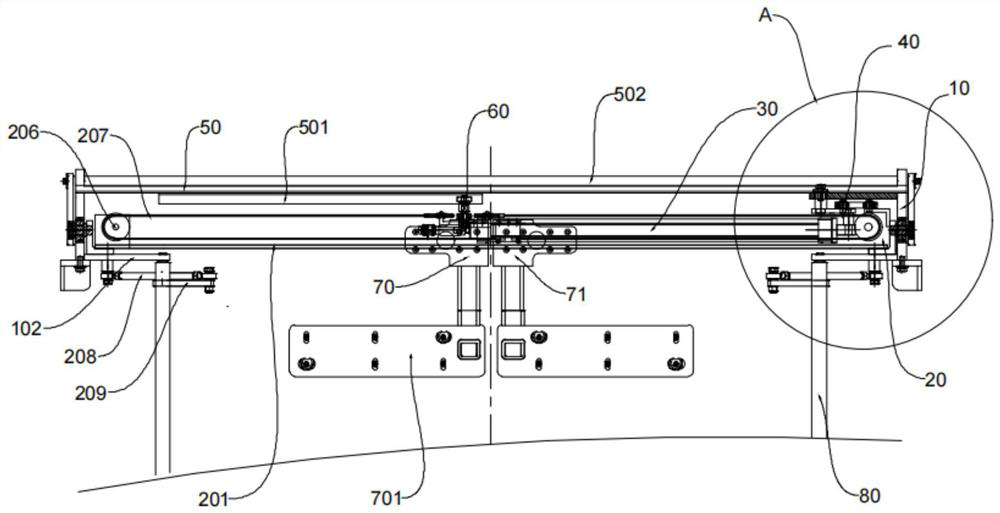

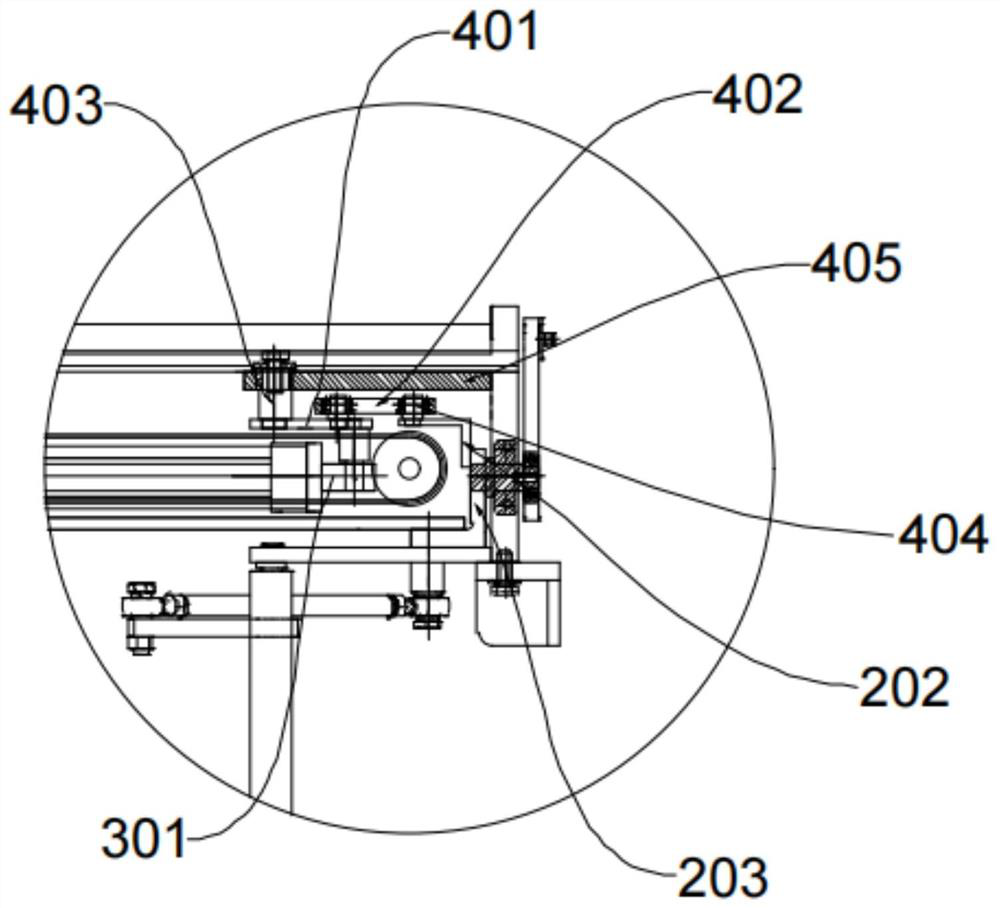

[0029] refer to figure 1 and figure 2 , the embodiment of the present invention provides a driving mechanism movement direction conversion device, including a fixed frame 10, a movable frame 20 and a power source 30, a guide wheel 60 is installed on the movable frame 20, a guide rail 501 is installed on the fixed frame 10, and the power source 30 can drive the guide wheel 60 to move in the guide rail 501. A link mechanism 40 is connected between the tailstock 301 of the power source and the movable frame 20. When the guide wheel 60 passes through the curve of the guide rail 501, the link mechanism 40 can drive the movable frame. 20 moves on the fixed frame 10, and the movable frame 20 can drive the guide wheel 60 to move longitudinally in the guide rail 501 relative to the straight part of the guide rail. That is, the link mechanism 40 drives the movable frame 20 to move on the fixed frame 10 through the reaction force of the power source 30 when the guide wheel 60 passes th...

Embodiment 2

[0032] refer to figure 1 and figure 2, the embodiment of the present invention provides a driving mechanism movement direction conversion device, on the basis of the first embodiment, wherein, the two ends of the movable frame 20 are installed on the fixed frame 10, and the fixed frame 10 is provided with a fixed tray 50, a guide rail 501 Located under the fixed tray 50, the link mechanism 40 includes a first link 401 and a second link 402, the two ends of the first link 401 rotate respectively to connect the tailstock 301 of the power source and the fixed tray 50, and the second link 402 The two ends rotate respectively to connect the first connecting rod 401 and the movable frame 20, and the tailstock 301 of the power source reacts to drive the first connecting rod 401 and the second connecting rod 402 to form a movable lever. , the steering force reaches its maximum. Let the connecting point between the first connecting rod 401 and the second connecting rod 402 be a leve...

Embodiment 3

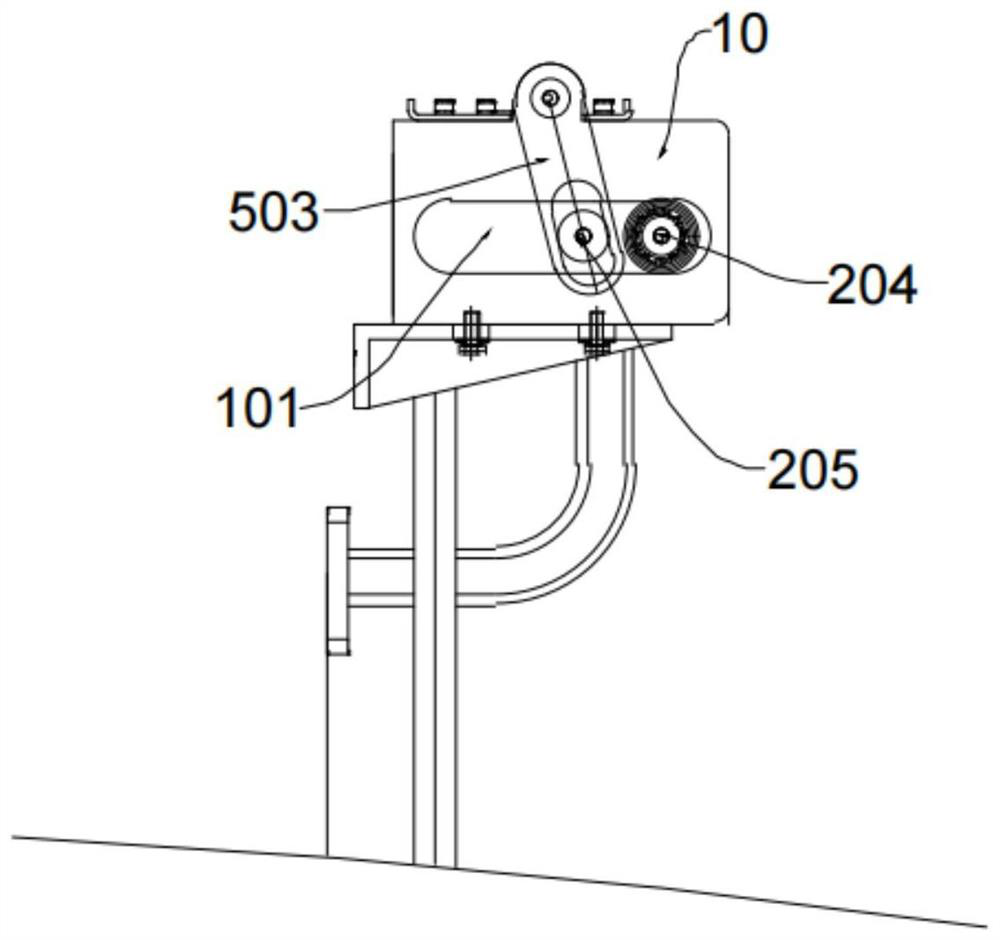

[0037] The embodiment of the present invention provides a device for changing the direction of motion of the drive mechanism. On the basis of Embodiment 1, refer to image 3 , wherein, the fixed frame 10 is provided with a bearing groove 101, and the two ends of the movable frame 20 are respectively provided with a driving bearing 204 and a driven bearing 205, and the driving bearing 204 and the driven bearing 205 are all movably installed in the bearing groove 101, and the driven bearing 205 and the fixed tray 50 are connected with a synchronous swing arm 503, and a synchronous lever 502 is connected between the synchronous swing arms 503 on both sides. Movement in the bearing groove 101, at the same time, because the driven bearing 205 is connected with the synchronous lever 502 through the synchronous swing arm 503, the movable frames 20 on both sides are synchronously oscillated to carry out longitudinal movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com