Betaine type amphiphilic polymer supramolecular oil displacement system and construction method thereof

A technology of amphiphilic polymer and betaine, which is applied in the direction of drilling compositions, chemical instruments and methods, and production fluids, etc. It can solve the problem of reduced viscosity increasing ability, reduced viscosity, and reduced ability to control water-oil mobility ratio, etc. problem, achieve the effect of reducing water-oil mobility ratio, increasing swept volume, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

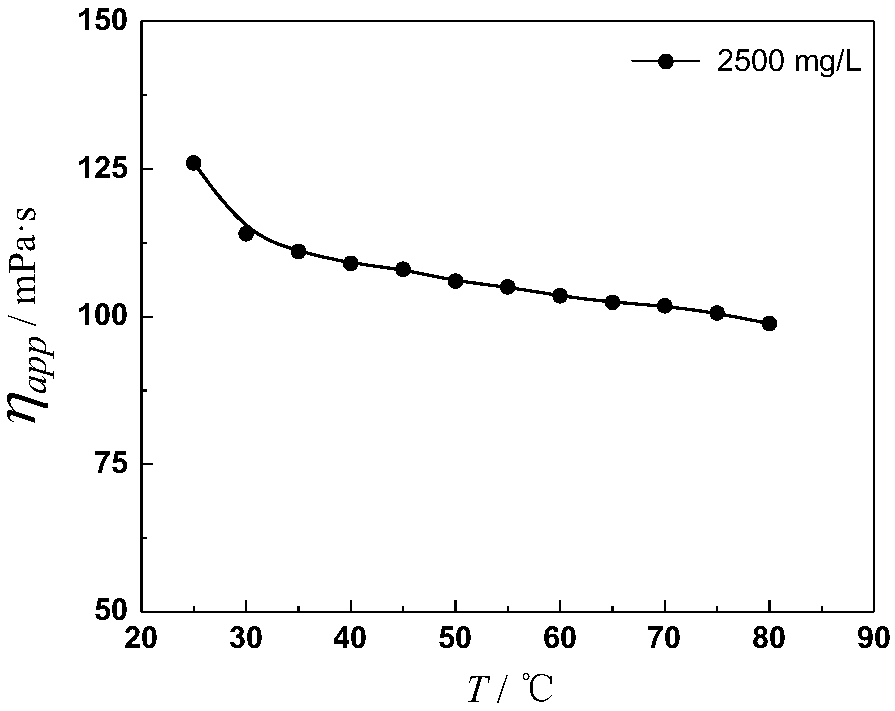

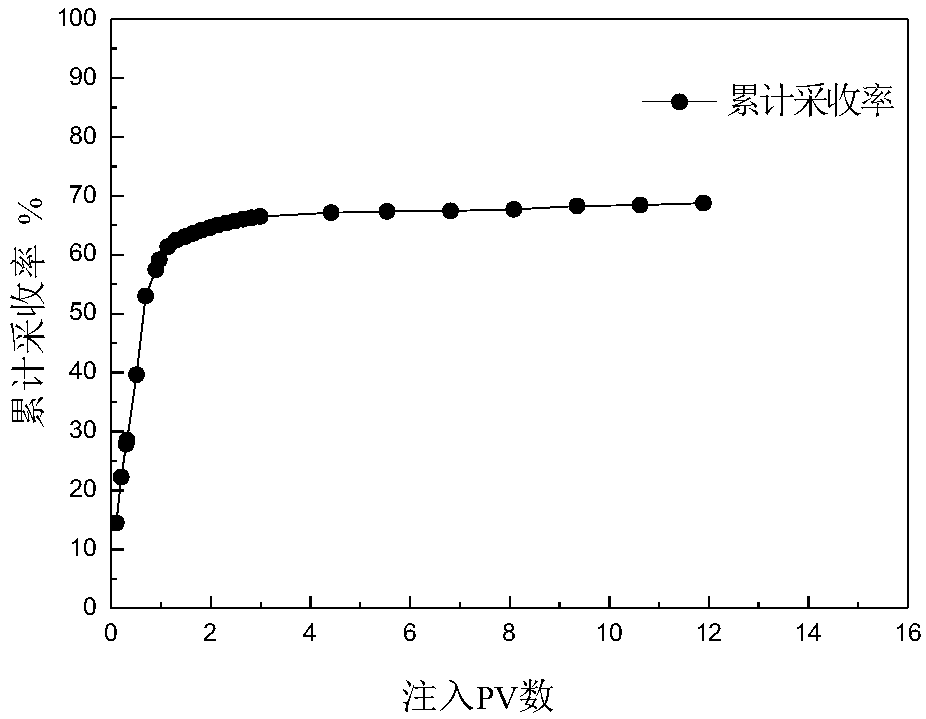

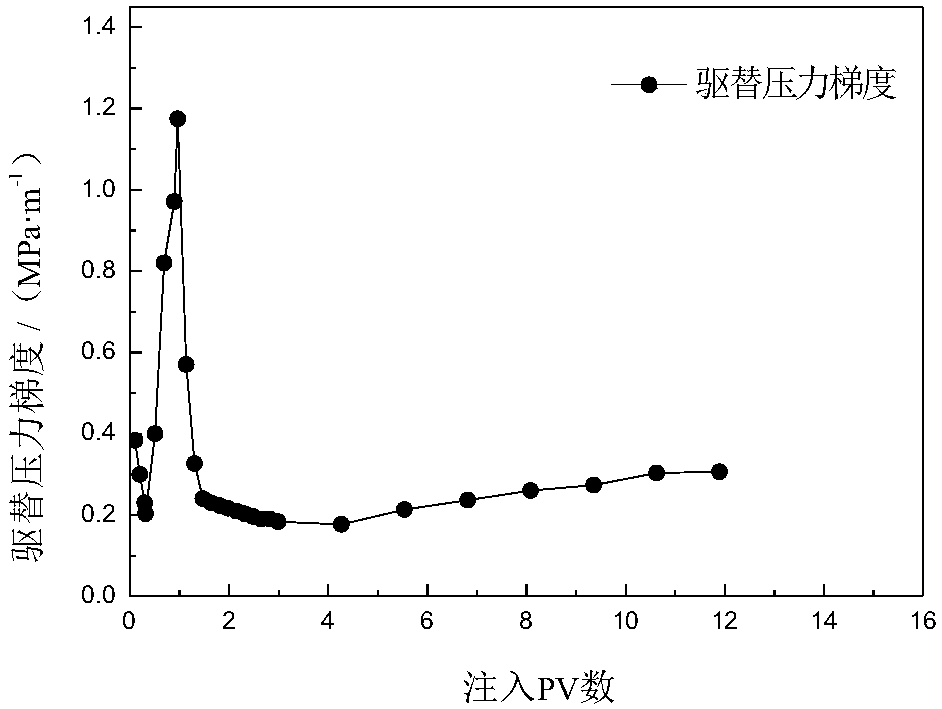

[0041] This implementation example provides a betaine type amphiphilic polymer supramolecular oil displacement system, prepare mineralized water with a salinity of 19000.7 mg / L (see Table 1 for the ion composition of the mineralized water), stir for 1 hour, and mix well , to ensure complete dissolution; add 0.25wt% betaine-type amphiphilic polymer (formula I, betaine monomer N,N-dimethyl-N-methacrylamidopropyl- The molar ratio of N-propanesulfonic acid inner salt is 20%, the molar ratio of hydrophobic monomer N,N-dimethylhexadecyl allyl ammonium chloride is 1.5%, and the relative molecular weight of the polymer is about 650×10 4 . ), stirred for 4 hours to ensure that the polymer was fully dissolved and mixed uniformly, and the solution was left to mature for 24 hours in a 45°C incubator; 0.07wt% citric acid was added to the prepared polymer solution and stirred for 2 hours to ensure that the lemon The acid is fully dissolved and mixed evenly, and the pH value of the solution...

Embodiment 2

[0049] This implementation example provides a betaine type amphiphilic polymer supramolecular oil displacement system, prepare 4500mg / L NaCl solution as mineralized water, stir for 0.5 hour, mix well, ensure complete dissolution; Add 0.20wt% betaine-type amphiphilic polymer (formula II, betaine monomer N, N-dimethyl-N-methacrylamidopropyl-N-propanesulfonic acid inner salt (DMMPPS) molar ratio 20%, the molar ratio of hydrophobic monomer N,N-dimethyldodecyl to vinyl benzyl ammonium chloride is 1.5%, and the relative molecular weight of the polymer is about 810×10 4 ), stirred for 6 hours to ensure that the polymer was fully dissolved and mixed evenly, and the solution was left to mature for 24 hours in a thermostat at 45°C; 0.05wt% disodium edetate was added to the prepared polymer solution, and stirred 2 hours, ensure full dissolution and uniform mixing, adjust the pH value of the solution to 8.5, its viscosity is 171.5mPa·s at 85°C, the viscometer speed is 6rpm, and the polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com