Preparation methods of biodegradable yoghourt-cup material and product

A biodegradable, yogurt cup technology, applied in the field of polymer materials, can solve problems such as poor barrier properties of polylactic acid, achieve good mechanical strength, reduce product costs, and expand application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 55 parts of polylactic acid, 35 parts of thermoplastic hydrophobic starch, 10 parts of polybutylene adipate-terephthalate, 0.7 parts of nucleating agent superfine talc powder, 1 part of chain extender, 0.3 parts of crosslinking agent, phase 0.15 parts of container;

[0035] The twin-screw extruder is granulated, and after drying, it is extruded into a sheet by a sheet machine, and the finished product of the yogurt cup is obtained by blistering of the plastic machine; the melting and blending temperature of the twin-screw extruder is 170-190°C, and The rotation speed is 200r / min, the heating temperature of the blister machine is 60°C, the vacuuming time is 14s, the cooling time is 16s, and the heating time is 17s.

Embodiment 2

[0037] 65 parts of polylactic acid, 25 parts of thermoplastic hydrophobic starch, 7.5 parts of polybutylene adipate-terephthalate, nucleating agent nano-SiO 2 0.5 parts, 0.75 parts of chain extender, 0.2 parts of crosslinking agent, 0.12 parts of compatibilizer;

[0038] The twin-screw extruder granulates, and after drying, it is extruded into a sheet by a sheet machine, and the finished product of the yogurt cup is obtained by absorbing the plastic machine. The rotation speed is 200r / min, the heating temperature of the blister machine is 67.5°C, the vacuuming time is 14.5s, the cooling time is 16.5s, and the heating time is 19.5s.

Embodiment 3

[0040] 75 parts of polylactic acid, 15 parts of thermoplastic hydrophobic starch, 5 parts of polybutylene adipate-terephthalate, 0.3 part of nucleating agent trimesic acid triamide, 0.5 part of chain extender, 0.1 part of crosslinking agent , 0.1 part of compatibilizer;

[0041] The twin-screw extruder granulates, and after drying, it is extruded into a sheet by a sheet machine, and the finished product of the yogurt cup is obtained by blistering of the plastic machine. The rotation speed is 200r / min, the heating temperature of the blister machine is 75°C, the vacuuming time is 15s, the cooling time is 17s, and the heating time is 22s.

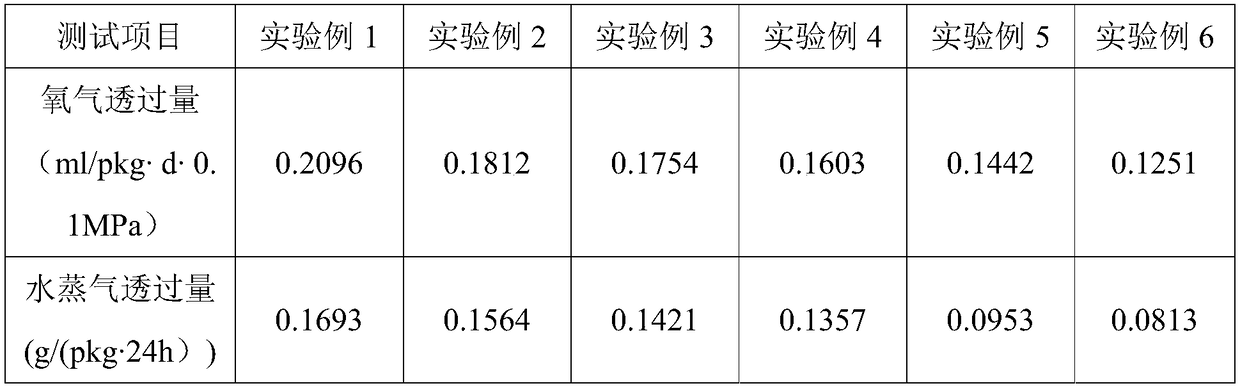

[0042] The effect of the thermoplastic hydrophobic base starch of the present invention is described below through an experimental example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com