PP-ST-DVB-based cation exchange fiber and synthesis method thereof

A PP-ST-DVB, 1. PP-ST-DVB technology, applied in the field of PP-ST-DVB-based cation exchange fiber material and its synthesis, fiber material and its synthesis, can solve the problem that carboxyl fibers are prone to collapse, easy Continue to solve problems such as hydrolysis and large fiber structure to achieve the effects of avoiding the use of carcinogens, easy control, good shape and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

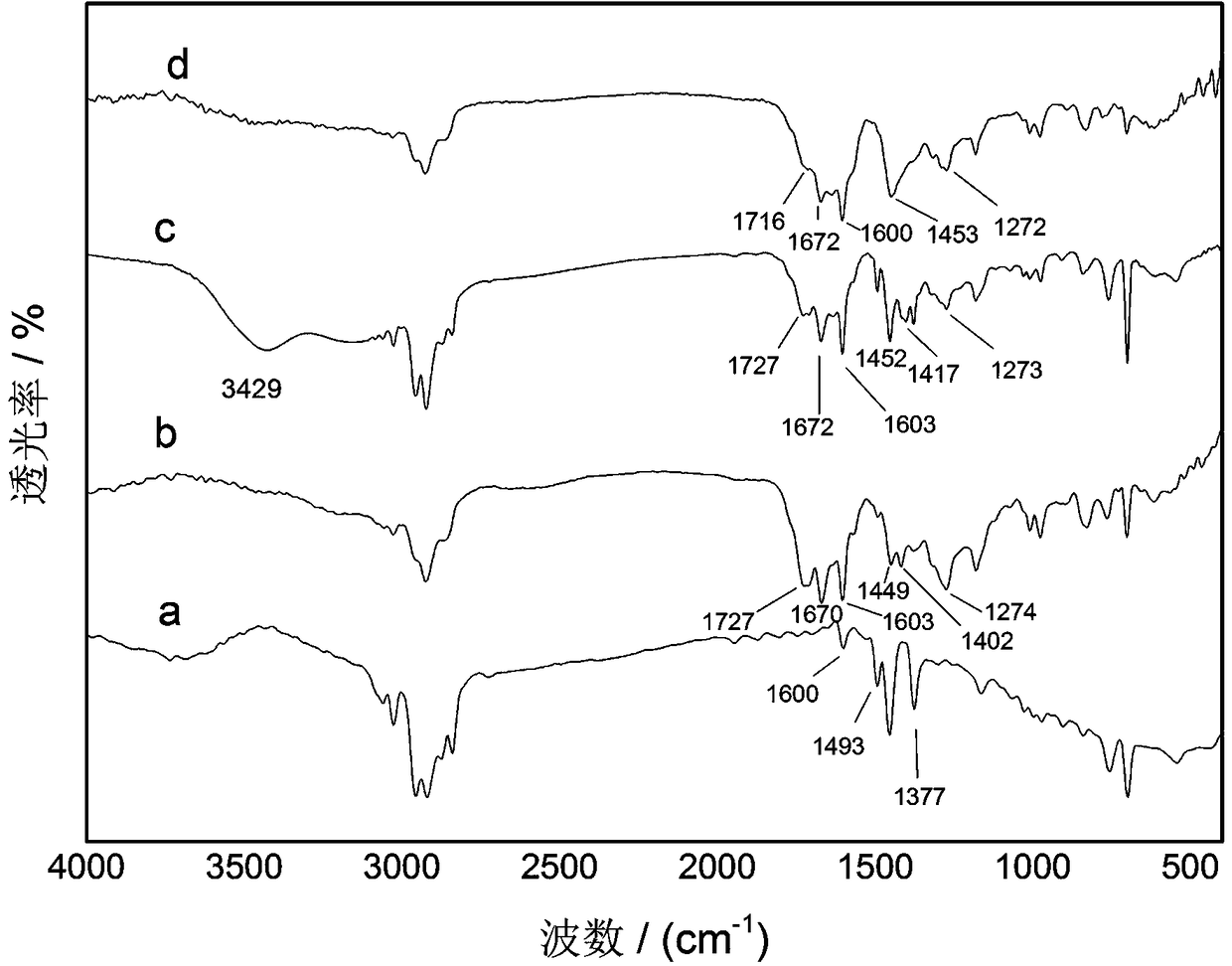

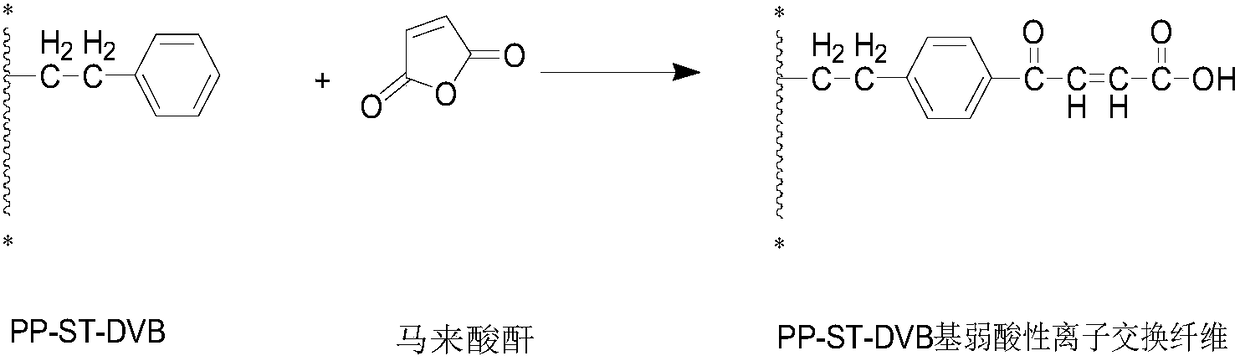

Embodiment 1

[0016] 4.2g of maleic anhydride, AlCl 3 -LiClO 4 Put 5.1g and 80mL of dichloromethane into a three-necked flask and stir to disperse them, put in 1g of pretreated PP-ST-DVB fiber (the grafting amount of ST-DVB is 350%), and control the temperature at 35°C for ultrasonic oscillation React for 1 hour under the same conditions, take out the fiber after the reaction, first extract the organic solvent in the fiber with absolute ethanol or acetone, and then wash it with deionized water until it is neutral; soak it with 0.5M acid for 12 hours, then wash it with deionized water until it is neutral. Neutral, dry to constant weight to obtain H-type PP-ST-DVB-based cation-exchange fibers; or according to the needs of use, the obtained H-type PP-ST-DVB-based cation-exchange fibers can be soaked in 0.5M NaOH solution for 12 hours, Wash with deionized water until neutral, and dry to constant weight to obtain Na-type PP-ST-DVB-based cation exchange fibers. The carboxyl group content was m...

Embodiment 2

[0018] Maleic anhydride 1.6g, FeCl 3 -LiClO 4Put 2.2g and 80mL of dichloroethane into a three-neck flask and stir, ultrasonically dissolve it, put in 1g of pretreated PP-ST-DVB fiber (the grafting amount of ST-DVB is 250%), and control the temperature at 20°C React for 2 hours under the condition of ultrasonic oscillation. After the reaction, take out the fiber, first extract the organic solvent in the fiber with absolute ethanol or acetone, and then wash it with deionized water until neutral; soak it in 0.5M acid for 12 hours, then wash it with deionized water Wash to neutral and dry to constant weight to obtain H-type PP-ST-DVB-based cation exchange fibers; or according to the needs of use, the obtained H-type PP-ST-DVB-based cation-exchange fibers can be soaked in 0.5M NaOH solution After 12 hours, wash with deionized water until neutral, and dry to constant weight to obtain Na-type PP-ST-DVB-based cation exchange fibers. The carboxyl group content was measured to be 7.4 ...

Embodiment 3

[0020] Succinic anhydride 0.7g, FeCl 3 -LiClO 4 Put 1.0g and 120mL of nitrobenzene into a three-necked flask and stir to dissolve, put in 1g of pretreated PP-ST-DVB fiber (the grafting amount of ST-DVB is 300%), and control the temperature at 10°C for ultrasonic oscillation React for 8 hours under the same conditions. After the reaction, take out the fiber, first extract the organic solvent in the fiber with absolute ethanol or acetone, and then wash it with deionized water until it is neutral; soak it with 0.5M acid for 12 hours, then wash it with deionized water until Neutral, dry to constant weight to obtain H-type PP-ST-DVB-based cation exchange fibers; or according to the needs of use, the obtained H-type PP-ST-DVB-based cation exchange fibers can be soaked in 0.5M NaOH solution for 12 hours , washed with deionized water to neutrality, and dried to constant weight to obtain Na-type PP-ST-DVB-based cation exchange fibers. The carboxyl group content was measured to be 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com