Preparation method for novel magnetic induction C3N4/Fe3O4 composite film and application of composite film

A technology of C3N4 and composite membranes, which is applied in chemical instruments and methods, chemical/physical processes, and water treatment of special compounds, etc., can solve problems such as catalyst embedding, achieve degradation, improve degradation efficiency, and improve photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034](1)C 3 N 4 / Fe 3 o 4 Preparation of composite catalyst

[0035] Weigh 20g of melamine in a crucible, dry it, transfer it to a muffle furnace, and calcinate it at 550°C for 4h with a heating rate of 2.3°C / min, take it out after natural cooling, and grind it into powder with a mortar to obtain C 3 N 4 Photocatalyst, stand-by; take 2.3gC 3 N 4 Dispersed in a mixture of 600mL ethanol and water (1:3), ultrasonicated to obtain C 3 N 4 Dispersion; take 0.27g FeCl 3 ·6H 2 O and 0.099 g FeCl 2 4H 2 O was dissolved in 20ml deionized water and poured into C 3 N 4 In the dispersion liquid, stir at 80 degrees Celsius for 1 hour, then immediately inject 10ml of ammonia water, and stir for 1 hour to obtain C 3 N 4 / Fe 3 o 4 composite photocatalyst.

[0036] (2) Magnetic induction C 3 N 4 / Fe 3 o 4 Catalytic membrane prepared from composite materials

[0037] Take 0.1g C 3 N 4 / Fe 3 o 4 Add the composite photocatalyst to 17.9g DMSO, ultrasonically disperse for...

Embodiment 2

[0039] Under the condition that other conditions are kept unchanged, establish a comparative test as follows: make C 3 N 4 / Fe 3 o 4 When composite catalyst, take 2.3g C 3 N 4 Dispersed in 40mL of water, ultrasonically dissolved to obtain C 3 N 4 Dispersion; take 1.622g FeCl 3 ·6H 2 O and 0.596g FeCl 2 4H 2 O was dissolved in 20 ml deionized water and added to the above C 3 N 4 In the dispersion liquid, stir at 80 degrees Celsius for 1 hour, then immediately inject 10ml of ammonia water, and stir for 1 hour to obtain C 3 N 4 / Fe 3 o 4 composite photocatalyst.

Embodiment 3

[0041] Preparation of magnetically induced C 3 N 4 / Fe 3 o 4 When the composite material photocatalytic film (other conditions remain unchanged), by changing the magnetic induction time (30min, 60min, 180min) to investigate the influence of induction time on the migration process of the catalyst, as well as the effect on the photocatalytic degradation effect; preparation of magnetic induction C 3 N 4 / Fe 3 o 4 When the composite material photocatalytic film (other conditions remain unchanged), by changing the amount of PVDF added (1g, 3g, 4g) to investigate the influence of the viscosity coefficient of the casting solution on the magnetic field induction, so as to further explore the optimal Matching. The catalytic membrane constructed under magnetic induction has a degrading effect of more than 90% on methyl orange.

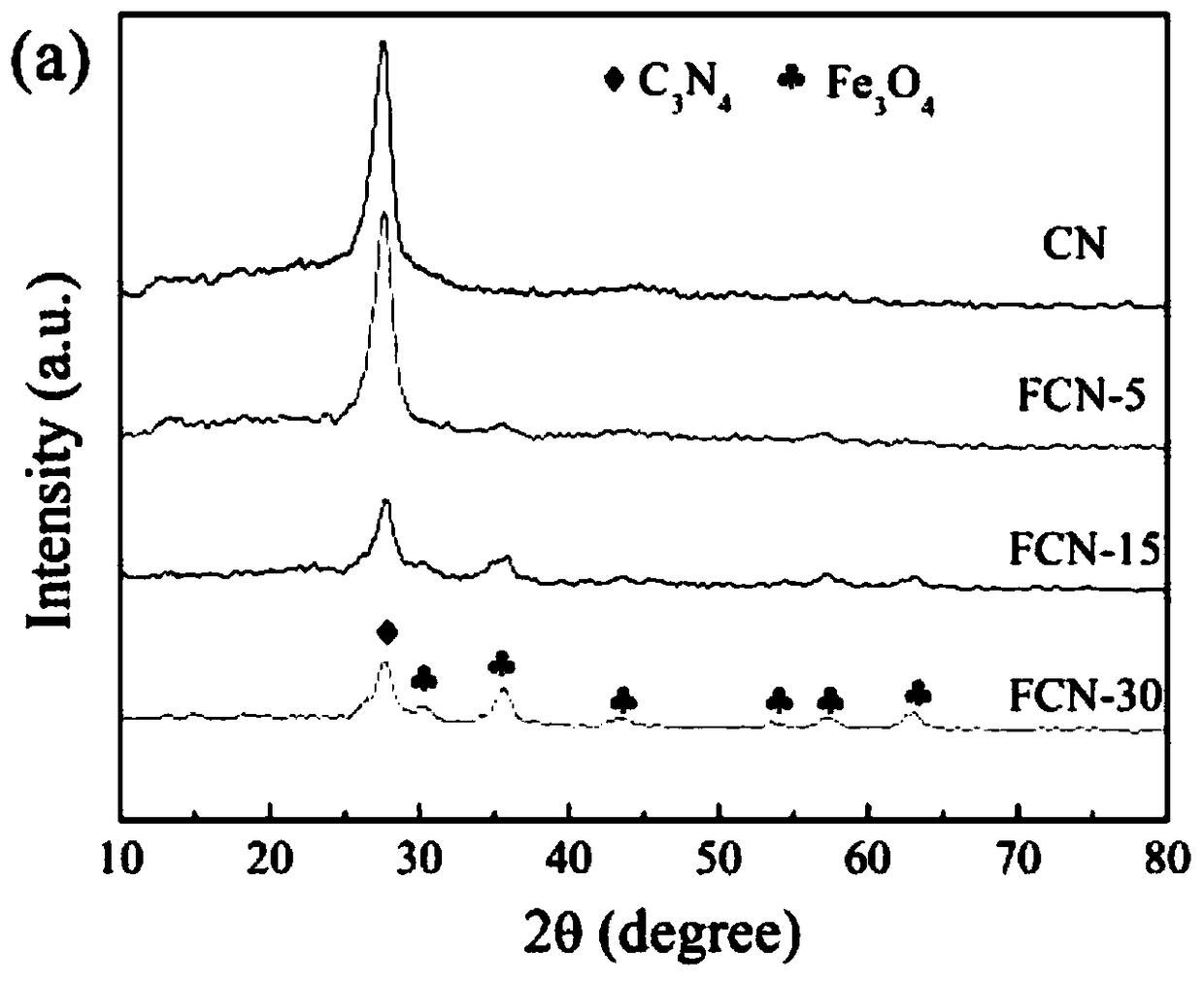

[0042] from figure 2 It can be seen that the composite material has Fe 3 o 4 and C 3 N 4 characteristic peaks, proving the successful synthesis of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com