A method for producing a light-emitting device

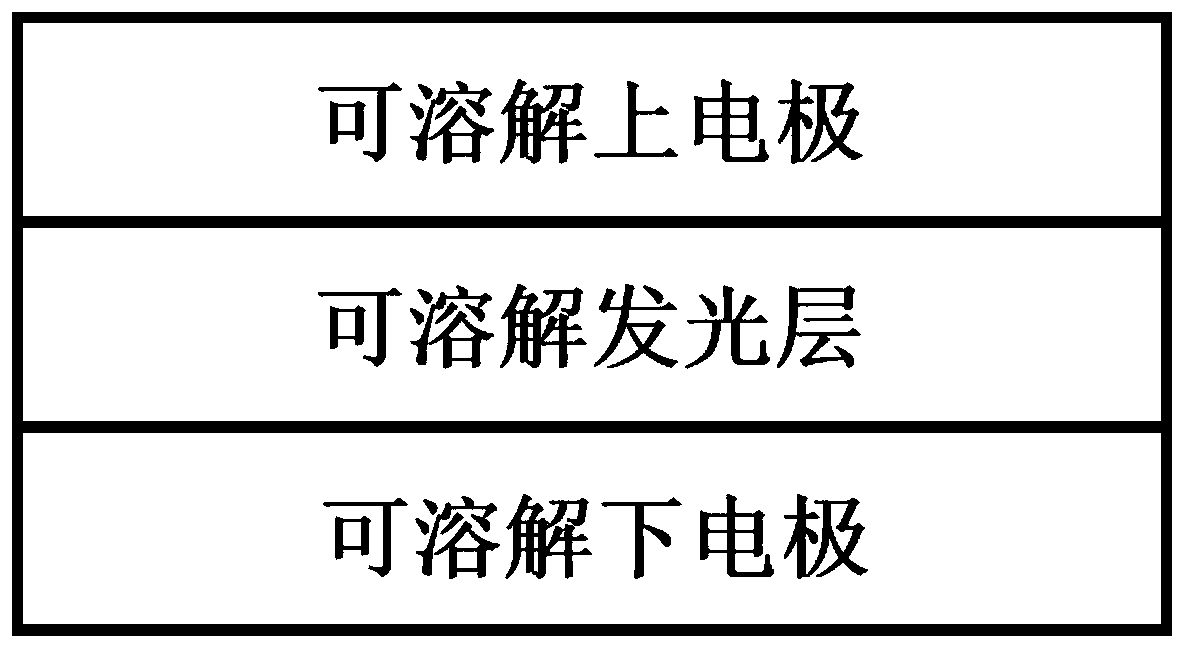

A technology for light-emitting devices and light-emitting layers, which is applied in the field of preparation of dissolvable light-emitting devices, can solve problems such as missing, and achieve the effects of reduced roughness, simple method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Ag nanowires synthesized by polyol method were used as device electrode materials. 0.01g of sodium bromide, 0.66g of polyvinylpyrrolidone, 16ml of ethylene glycol solution were added to the reactor, heated by stirring, wherein the stirring speed was 200rpm, and the heating temperature was 165°C, then 0.05g of silver chloride powder was added to react. After 3min, 4ml of silver nitrate ethylene glycol solution containing 0.22g was slowly added, the dropping rate was 0.4ml / min, and cooled to room temperature after 30min. Finally, the obtained solution was centrifuged at 2000 rpm for 30 min, the lower sediment was discarded, and the upper layer was retained, and then 4 times the volume of ethanol of the upper solution was added and centrifuged at 6000 rpm, the supernatant was removed, and the procedure was repeated 3 times to obtain a silver nanowire ethanol solution.

[0038] 2) Configure 30mg / ml polyvinyl alcohol aqueous solution for the preparation of the lower elect...

Embodiment 2

[0049]1) Silver nanowires synthesized by polyol method are used as device electrode materials. Add 0.01g sodium bromide, 0.66g polyvinylpyrrolidone, 16ml ethylene glycol solution in the reactor, heat by stirring, wherein the stirring speed is 200rpm, and the heating temperature is 165°C, then add 0.05g of silver chloride powder, react After 3 minutes, slowly add 4ml of silver nitrate ethylene glycol solution containing 0.22g at a rate of 0.4ml / min, and cool to room temperature after 30 minutes. Finally, by centrifuging the obtained solution at 2000rpm for 30min, discarding the lower precipitate and retaining the upper layer, then adding ethanol with 4 times the volume of the upper layer solution and centrifuging at 6000rpm, removing the supernatant, repeating 3 times, and then obtaining the silver nanowire ethanol solution.

[0050] 2) Configure 60mg / ml polyvinyl alcohol aqueous solution for the preparation of the lower electrode, weigh 1.2g polyvinyl alcohol powder, add 20ml ...

Embodiment 3

[0059] 1) Silver nanowires synthesized by polyol method are used as device electrode materials. Add 0.01g sodium bromide, 0.66g polyvinylpyrrolidone, 16ml ethylene glycol solution in the reactor, heat by stirring, wherein the stirring speed is 200rpm, and the heating temperature is 165°C, then add 0.05g of silver chloride powder, react After 3 minutes, slowly add 4ml of silver nitrate ethylene glycol solution containing 0.22g at a rate of 0.4ml / min, and cool to room temperature after 30 minutes. Finally, by centrifuging the obtained solution at 2000rpm for 30min, discarding the lower precipitate and retaining the upper layer, then adding ethanol with 4 times the volume of the upper layer solution and centrifuging at 6000rpm, removing the supernatant, repeating 3 times, and then obtaining the silver nanowire ethanol solution.

[0060] 2) Configure 20mg / ml polyvinyl alcohol aqueous solution for the preparation of the lower electrode, weigh 0.4g polyvinyl alcohol powder, add 20ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com