Efficient non-phosphorus reverse osmosis scale-inhibiting dispersant

A technology of scale inhibitor and reverse osmosis membrane, which is applied in the field of scale inhibitor and dispersant for phosphorus-free reverse osmosis, can solve the problems of phosphate precipitation pollution of membrane elements, reduce membrane flux, increase membrane cleaning times, etc., and achieve elimination of biological pollution. And the hidden danger of bacteria exceeding the standard, excellent control ability, and the effect of providing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

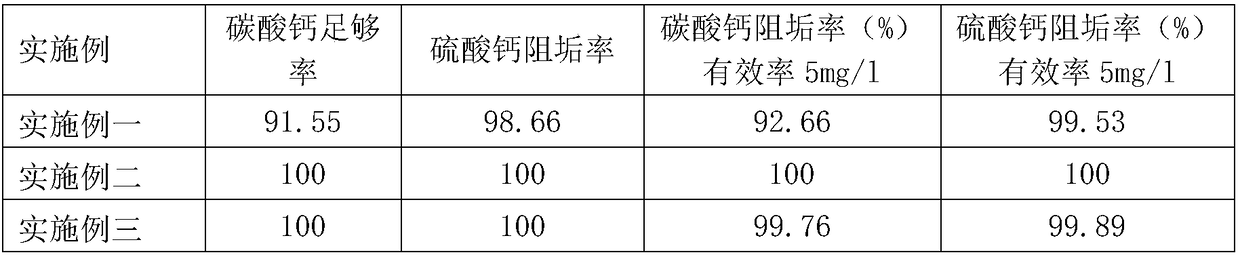

Examples

no. 1 example ;

[0031] 2.1 parts of PH regulator;

[0032] 12 parts of sodium styrene sulfonate polymer;

[0033] 38 parts of carboxylate polymer;

[0034] 1.5 parts of aldehydes;

[0035] 10 parts of carboxylic acid polymer;

[0036] 10 parts of sulfonic acid copolymer;

[0037] 5 parts of dioctadecyl dimethyl ammonium bromide;

[0038] 5 parts gelatin;

[0039] 5 parts of deionized water;

[0040] Its preparation steps are as follows:

[0041] 1) the pH regulator, sodium styrene sulfonate polymer, carboxylic acid copolymer, aldehydes, sulfonic acid copolymer, polyamino acid, dioctadecyl dimethyl ammonium bromide and deionized water Add to the container at room temperature, stir until a uniform and transparent solution;

[0042] 2) Add gelatin, raise the temperature to 35-45 degrees, stir evenly to form a transparent solution;

[0043] 3) Insert the trachea connected to the high-pressure air source into the solution, the air pressure is between 1.5-3 atmospheres, the gas outlet end ...

no. 2 example

[0047] 3.5 parts of pH regulator;

[0048] 14 parts of sodium styrene sulfonate polymer;

[0049] 50 parts of carboxylate polymer;

[0050] 2.5 parts of aldehydes;

[0051] 15 parts of carboxylic polymers;

[0052] 20 parts of sulfonic acid copolymer;

[0053] 15 parts of dioctadecyl dimethyl ammonium bromide;

[0054] 8 parts gelatin;

[0055] 10 parts of deionized water;

[0056] Its preparation steps are as follows:

[0057] 1) the pH regulator, sodium styrene sulfonate polymer, carboxylic acid copolymer, aldehydes, sulfonic acid copolymer, polyamino acid, dioctadecyl dimethyl ammonium bromide and deionized water Add to the container at room temperature, stir until a uniform and transparent solution;

[0058] 2) Add gelatin, raise the temperature to 35-45 degrees, stir evenly to form a transparent solution;

[0059] 3) Insert the trachea connected to the high-pressure air source into the solution, the air pressure is between 1.5-3 atmospheres, the air outlet end of...

no. 3 example

[0063] 2.8 parts of pH regulator;

[0064] 13 parts of sodium styrene sulfonate polymer;

[0065] 45 parts of carboxylate polymer;

[0066] 2 parts of aldehydes;

[0067] 12.5 parts of carboxylic polymers;

[0068] 15 parts of sulfonic acid copolymer;

[0069] 10 parts of dioctadecyl dimethyl ammonium bromide;

[0070] 6 parts gelatin;

[0071] 7 parts deionized water;

[0072] Its preparation steps are as follows:

[0073] 1) the pH regulator, sodium styrene sulfonate polymer, carboxylic acid copolymer, aldehydes, sulfonic acid copolymer, polyamino acid, dioctadecyl dimethyl ammonium bromide and deionized water Add to the container at room temperature, stir until a uniform and transparent solution;

[0074] 2) Add gelatin, raise the temperature to 35-45 degrees, stir evenly to form a transparent solution;

[0075] 3) Insert the trachea connected to the high-pressure air source into the solution, the air pressure is between 1.5-3 atmospheres, the air outlet end of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com