Lithium ion battery negative electrode material, lithium ion battery negative electrode plate and preparation method thereof and lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of easy detachment of negative electrode active materials and reduced cycle life of lithium ion batteries, and achieves convenient operation and improved Low temperature performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] According to a third aspect of the present invention, the present invention provides a method for preparing the above-mentioned lithium-ion battery negative plate, comprising the steps of:

[0064] (a) dispersing the lithium-ion battery negative electrode material in water to prepare the lithium-ion battery negative electrode slurry;

[0065] (b) Coating the negative electrode slurry of the lithium ion battery on the current collector, followed by drying and rolling to obtain the negative electrode sheet of the lithium ion battery.

[0066] The preparation method of the lithium ion battery negative plate provided by the present invention adopts cheap and pollution-free water as a solvent, and adopts an adhesive including a polyacrylamide adhesive as an adhesive, which reduces environmental pollution, saves energy, and at the same time The process is simple, the operation is convenient, and it can be applied to large-scale industrial production.

[0067] In a preferred ...

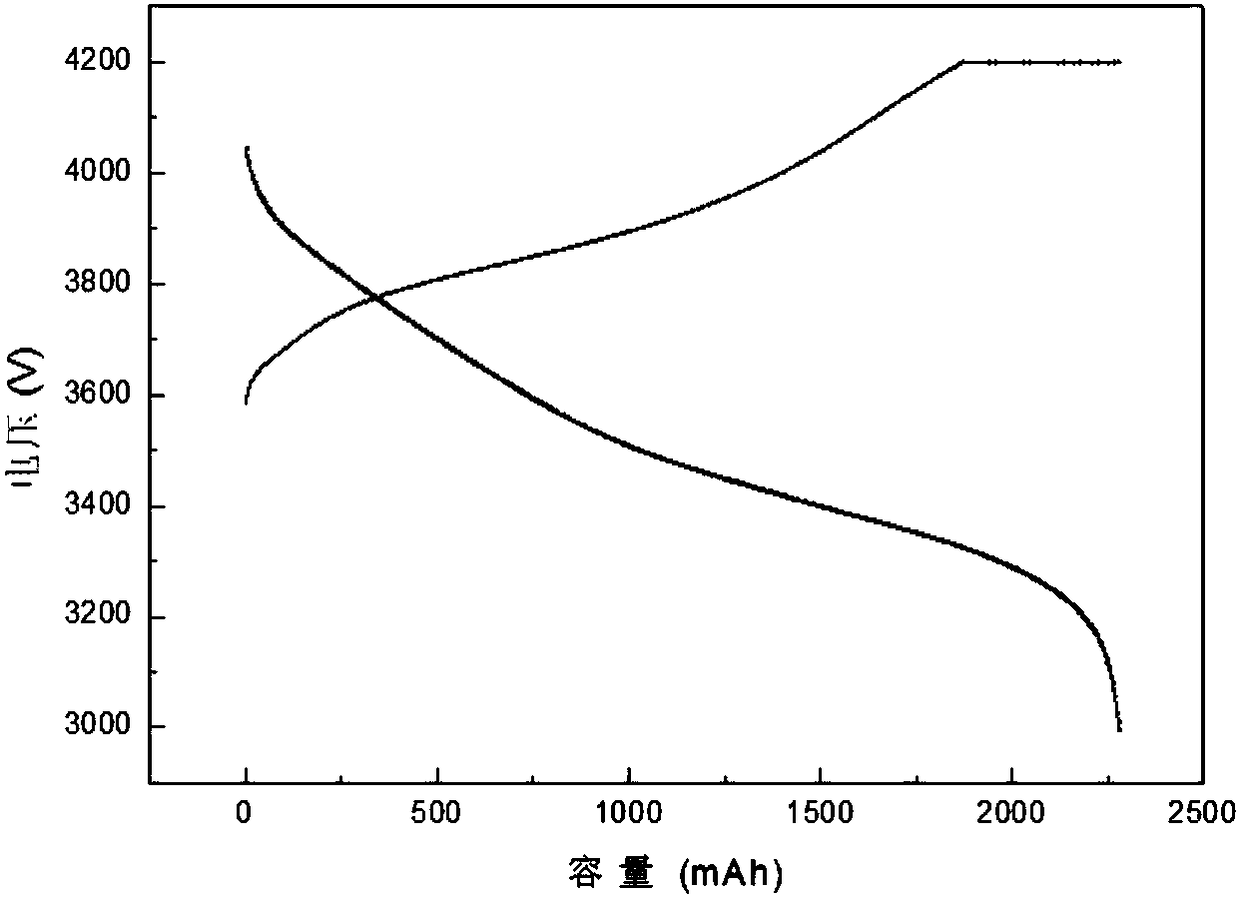

Embodiment 1

[0074] This embodiment provides a lithium-ion battery, including a lithium-ion battery positive electrode sheet and a lithium-ion battery negative electrode sheet, the lithium-ion battery negative electrode sheet is prepared by coating a lithium-ion battery negative electrode material on a copper foil, and the lithium-ion battery negative electrode sheet The material is prepared from the following raw materials: artificial graphite: 97wt%, polyacrylamide binder: 1wt%, LA132: 0.5wt% and carbon black: 1.5wt%; wherein, the polyacrylamide binder is acrylamide - Vinyl alcohol-n-butyl acrylate block copolymer, the number average molecular weight is 1 million, and the proportion of the polymer block of the acrylamide monomer unit is 50wt%, and the proportion of the polymer block of the vinyl alcohol monomer unit is 20wt% %, n-butyl acrylate monomer unit polymer block accounts for 30wt%.

[0075] The preparation steps of lithium ion battery negative plate are as follows:

[0076] (a)...

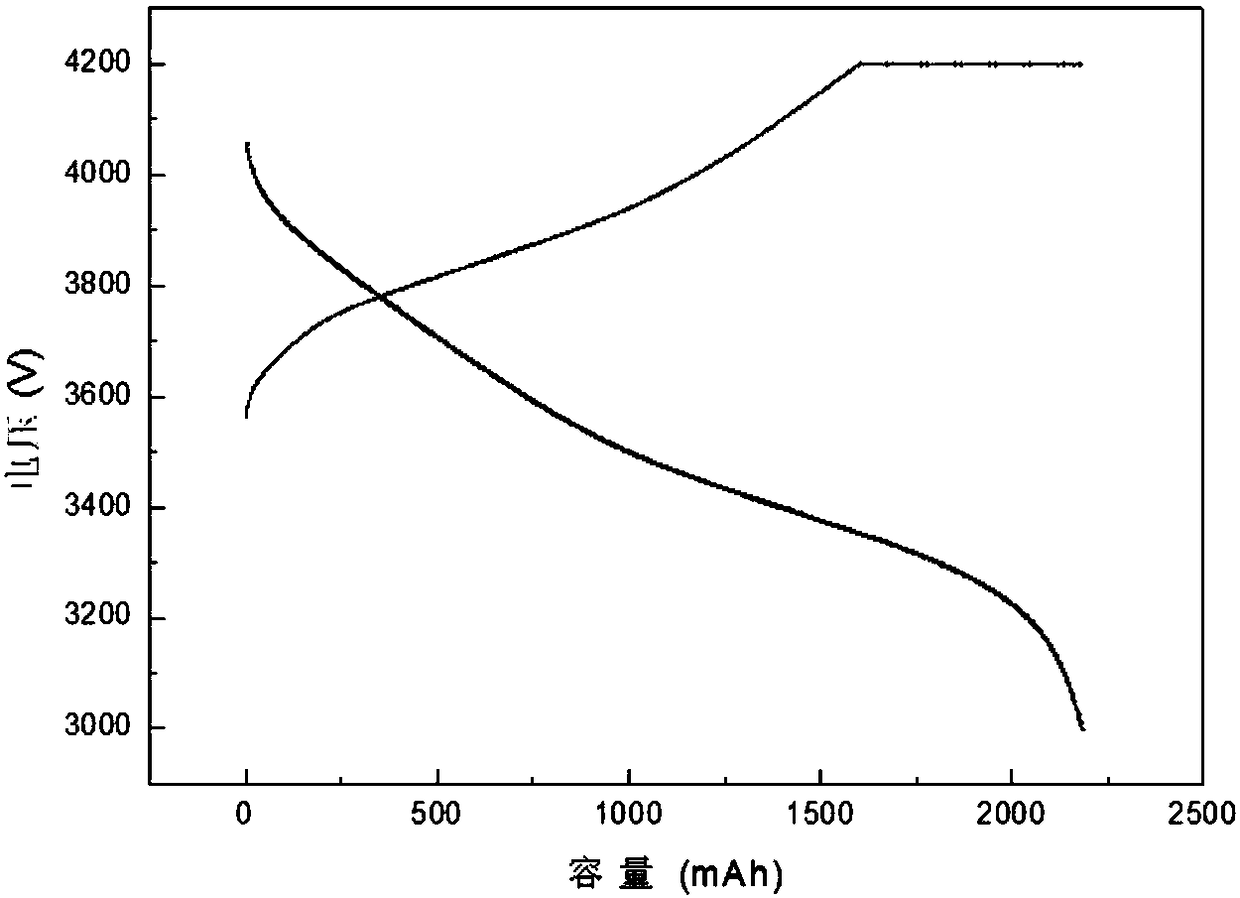

Embodiment 2

[0080] This embodiment provides a lithium-ion battery, including a lithium-ion battery positive electrode sheet and a lithium-ion battery negative electrode sheet, the lithium-ion battery negative electrode sheet is prepared by coating a lithium-ion battery negative electrode material on a copper foil, and the lithium-ion battery negative electrode sheet The material is prepared from the following raw materials: lithium titanate: 96.5wt%, polyacrylamide binder: 2.5wt%, carbon black: 1wt%; among them, the polyacrylamide binder is acrylamide-vinyl alcohol- N-hexyl acrylate block copolymer, the number average molecular weight is 22 million, and the proportion of polymer block of acrylamide monomer unit is 80wt%, the proportion of polymer block of vinyl alcohol monomer unit is 10wt%, n-butyl acrylate The ester monomer unit polymer block accounts for 10wt%.

[0081] The preparation steps of lithium ion battery negative plate are as follows:

[0082] (a) adding the negative electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com