Total-synthesis water-based cutting fluid for sapphire and preparation method of cutting fluid

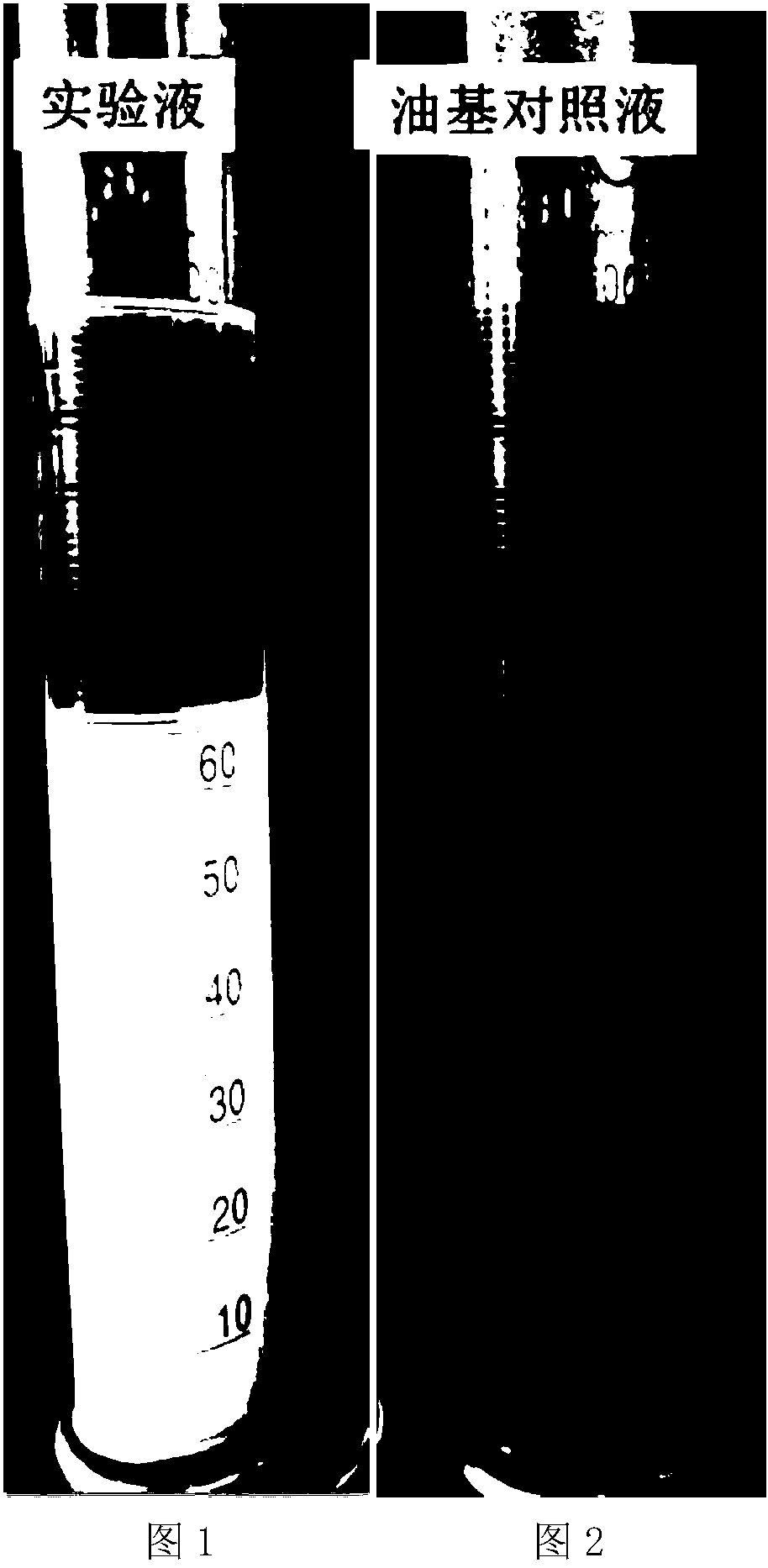

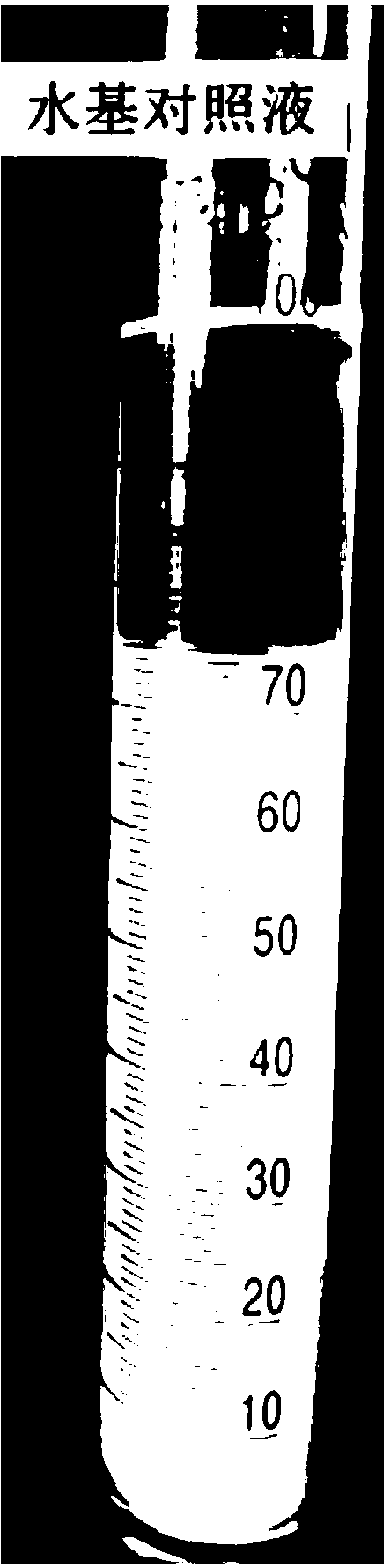

A sapphire and cutting fluid technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of insufficient wetting penetration, pungent odor, dry cutting wear, etc., achieve good sedimentation effect, improve wetting penetration, and lubricate extremely Pressure boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of fully synthetic water-based sapphire cutting fluid, its preparation method comprises the following steps:

[0040] (1) Weigh 10% trans polyether, 6% polyethylene glycol 600, 5% organic trivalent polycarboxylic acid, 5% borate, 1% phosphoric acid ester, 2% water-soluble DPZ, 0.25% modified cationic polyether, 0.25% polyoxyethylene dodecyl dimethyl ammonium bromide, 0.5% alkylisothiazolinone, 1.5% hydroxyethyl hexahydro-s-triazine, 0.5% secondary alcohol polyoxyethylene ether surfactant, 4% isononanoic acid, 3% diglycolamine, 7% triethanolamine, 0.5% silicone defoamer and 53.5% water;

[0041] (2) Put 53.5% of the water weighed in step (1) into the stirred reactor, then add 3% of diglycolamine and 7% of triethanolamine to it, stir until evenly mixed, then add 5% of Organic ternary polycarboxylic acid, 5% borate, heated to 60°C in a water bath and kept stirring until the solution in the kettle was transparent and uniform, then stopped heating;

[0042] (3) Add ...

Embodiment 2

[0044] A kind of fully synthetic water-based sapphire cutting fluid, its preparation method comprises the following steps:

[0045] (1) Weigh 12% of modified polyalkylene glycol, 6% of polyethylene glycol 600, 2% of sebacic acid, 8% of boric acid ester, 2% of phosphoric acid ester, 2% of water soluble Organic molybdenum, 0.5% modified cationic polyether, 0.5% polydichloroethyl ether tetramethylethylenediamine, 1% hydroxyethyl hexahydro-s-triazine, 1% iodopropynyl butyl Urethane, 0.8% silicone polyether surfactant, 3% isononanoic acid, 4% ethanolamine and 6% triethanolamine, 0.3% silicone defoamer and 50.9% water;

[0046] (2) Put 50.9% of the water weighed in step (1) into the stirred reactor, then add 4% ethanolamine and 6% triethanolamine therein, stir until the mixture is uniform, then add 2% sebacic acid and 8% boric acid ester, heated in a water bath to 60°C and kept stirring until the solution in the kettle was transparent and uniform, then stopped heating;

[0047] (3...

Embodiment 3

[0049] A kind of fully synthetic water-based sapphire cutting fluid, its preparation method comprises the following steps:

[0050] (1) Weigh 12% of modified polyalkylene glycol, 6% of glycerin, 3% of organic trivalent polycarboxylic acid, 5% of borate, 1% of phosphoric acid ester, 3% of water soluble Organic molybdenum, 0.5% modified cationic polyether, 1% polydichloroethyl ether tetramethylethylenediamine, 2.5% alkylisothiazolinone, 0.5% iodopropynyl alcohol butyl aminomethyl ester, 0.6% silicone polyether surfactant, 5% n-octanoic acid, 3% diethanolamine, 8% triethanolamine, 0.6% silicone defoamer and 48.3% water;

[0051] (2) Put 48.3% of the water weighed in step (1) into the stirred reactor, then add 3% of diethanolamine and 8% of triethanolamine to it, stir until evenly mixed, and then add 3% of organic triethanolamine Polycarboxylate and 5% borate, heated to 60°C in a water bath and kept stirring until the solution in the kettle was transparent and uniform, then stopp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com