A kind of processing method of dust-suppressing sludge solidifying agent

A processing method and curing agent technology, applied in chemical instruments and methods, fixed/solidified sludge treatment, sludge treatment, etc., can solve problems such as agglomeration and pilling, curing agent failure, etc., and achieve good dispersibility, wetting Good permeability, lowering temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

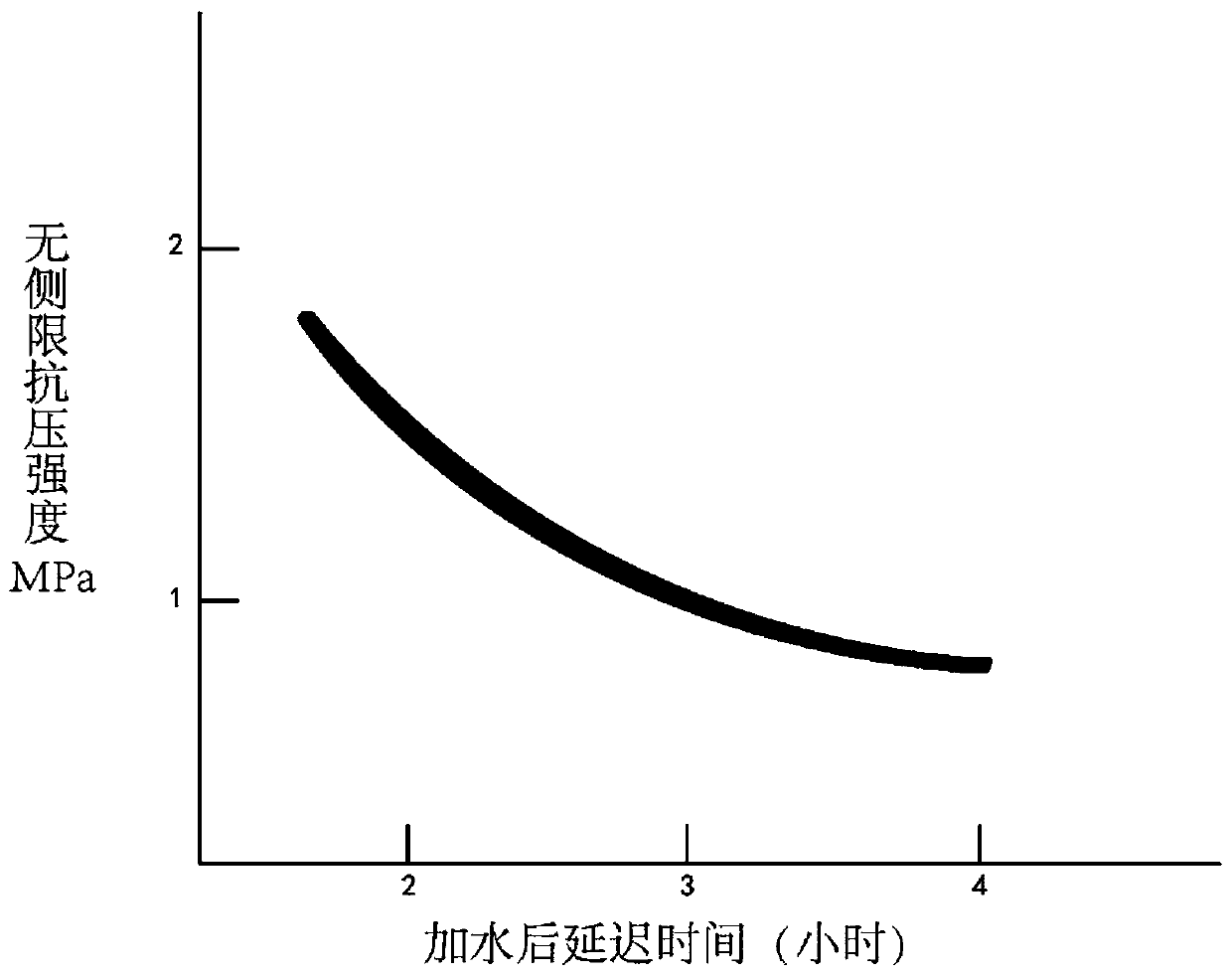

[0035] Example 1: Effect of Delay Time of Humidified Curing Agent on Unconfined Compressive Strength

[0036] Silt from Haixu Road, Sino-Singapore Tianjin Eco-city, with a moisture content of 89% and a wet density of 1.45g / cm 3 , the green belt solidification soil strength design site is 0.3Mpa, and the subgrade solidification design value site is 0.4Mpa; Carry out the influence of the delay time of humidification curing agent on the unconfined compressive strength in the laboratory, the curing agent used is embodiment 2 in CN101081718A Middle curing agent:

[0037] Sodium α-olefin sulfonate, nonylphenol polyoxyethylene ether and water are formulated into an aqueous surfactant solution, wherein the mass percentage of alpha-olefin sulfonate sodium is 0.05%, and the mass percentage of nonylphenol polyoxyethylene ether is 0.01% , The balance is tap water. The addition amount of the surfactant aqueous solution is 8% of the weight of the curing agent, and the usage amount of the ...

Embodiment 2

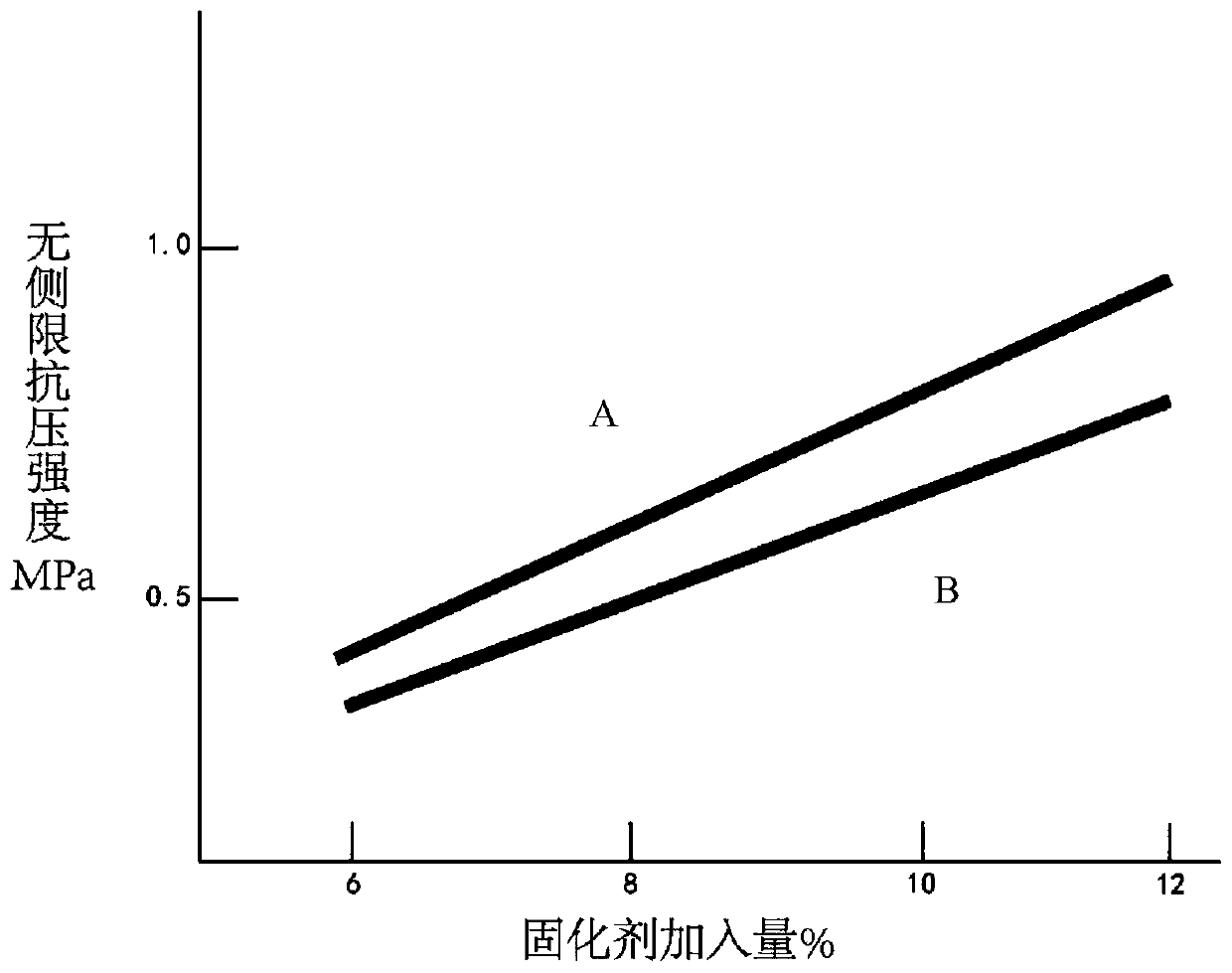

[0039] Example 2: The effect of humidified curing agent and the amount of curing agent used on the unconfined compressive strength

[0040] Humidification curing agent is used for the consolidation of the silt in the east (li) embankment of Sino-Singapore Tianjin Eco-city, the moisture content of the silt is 67%, and the wet density is 1.64g / cm 3 .

[0041]Sodium α-olefin sulfonate and water are prepared into an aqueous surfactant solution, wherein the mass percentage of sodium α-olefin sulfonate is 0.1%, and the balance is tap water. The curing agent in Example 2 in CN101081718A is placed in a double-helix mixer, and then the surfactant aqueous solution is sprayed into the double-helix mixer, and stirred while spraying, so that the curing agent is humidified evenly, thereby obtaining a humidification curing agent; surface active The addition of the aqueous solution of the curing agent is 8% of the weight of the curing agent. Put the humidifying and curing agent on an ordina...

Embodiment 3

[0045] Sino-Singapore Tianjin Eco-city Dongdi Road silt consolidation adopts humidification and curing agent, the moisture content of the silt is 67%, and the wet density is 1.64g / cm 3 .

[0046] Sodium α-olefin sulfonate and water are prepared into an aqueous surfactant solution, wherein the mass percentage of sodium α-olefin sulfonate is 0.1%, and the balance is tap water. The curing agent of Example 3 in CN101081718A is placed in a double-helix mixer, and then the surfactant aqueous solution is sprayed into the double-helix mixer, and stirred while spraying, so that the curing agent is humidified evenly, thereby obtaining a humidification curing agent; surfactant The added amount of aqueous solution is 8% of curing agent weight. Put the humidifying and curing agent on an ordinary light truck, cover it with a tarpaulin, transport it to the destination, and pour it directly on the mud. The usage of the humidifying and curing agent is 9% of the weight of the mud; then use the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com