Indexable cutting blade for cutting machining of engineering rubber materials

A technology for engineering rubber and cutting blades, which is applied in the direction of milling cutting blades, cutting blades, and tools for lathes, etc. It can solve the problems of large cutting resistance, low thermal conductivity of rubber materials, and difficult heat diffusion, etc., to increase the heat dissipation space , reduce heat, reduce the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

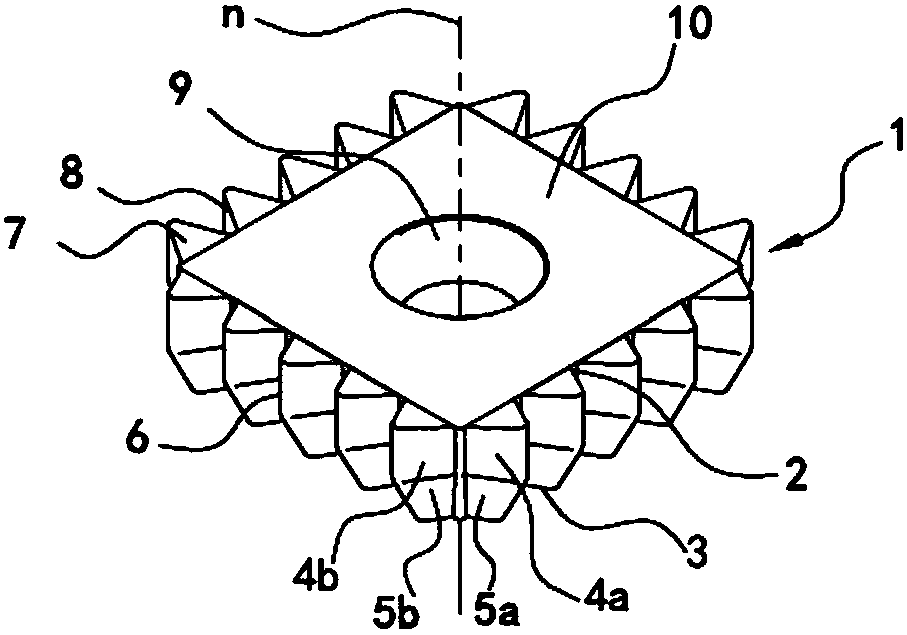

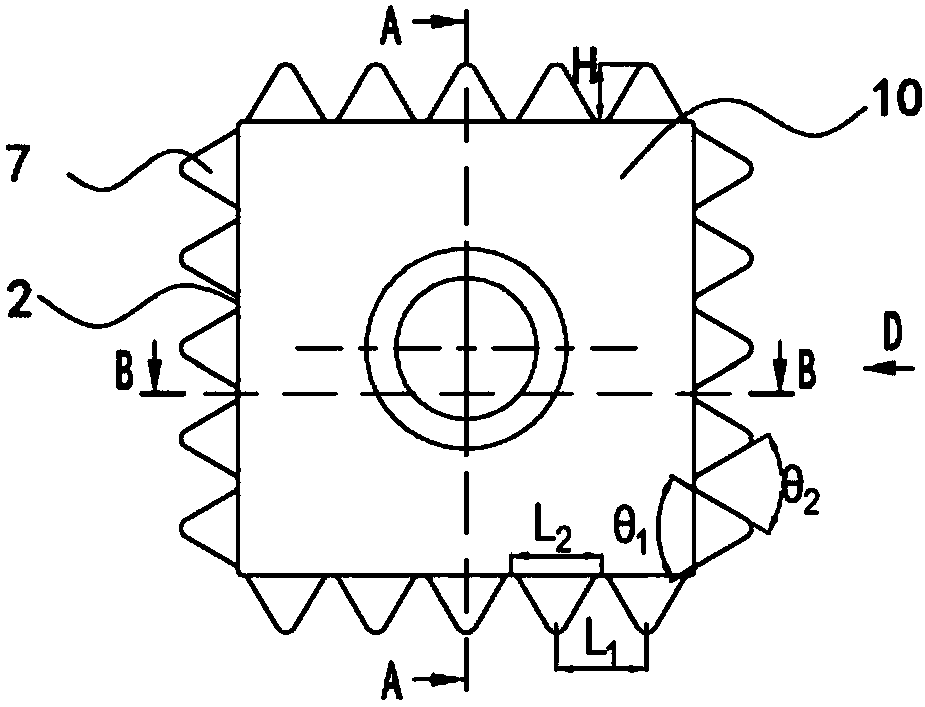

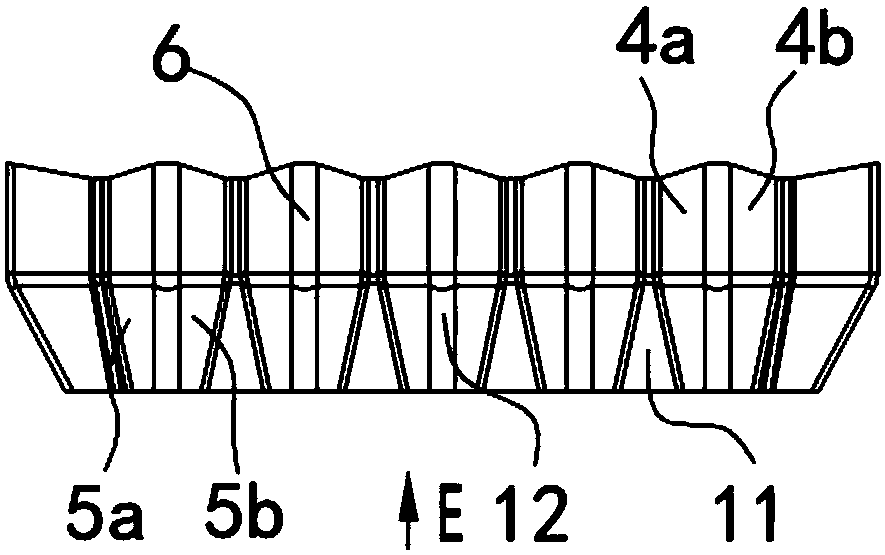

[0033] see Figure 1 to Figure 6 As shown, an indexable cutting insert for cutting engineering rubber materials according to the present invention includes an insert body 1 projected in a substantially square shape on a horizontal plane, and the insert body 1 includes an upper surface 10, a lower surface 3 and a surrounding The side of the periphery, and the lower surface 3 is a plane; a plurality of tooth-shaped protrusions are also extended outward on the side of the blade body 1, which makes each side of the blade body 1 form a tooth-shaped structure when projected on a horizontal plane. The edge of the upper surface of the convex portion forms the cutting edge portion 8, and the projection of the cutting edge portion 8 on the horizontal plane is tooth-shaped. The rake face 7 and the flanks of the tooth-shaped protrusion constitute the flank of the cutting insert, and the flank is at least two faces from top to bottom. The flank is composed of at least two faces, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com