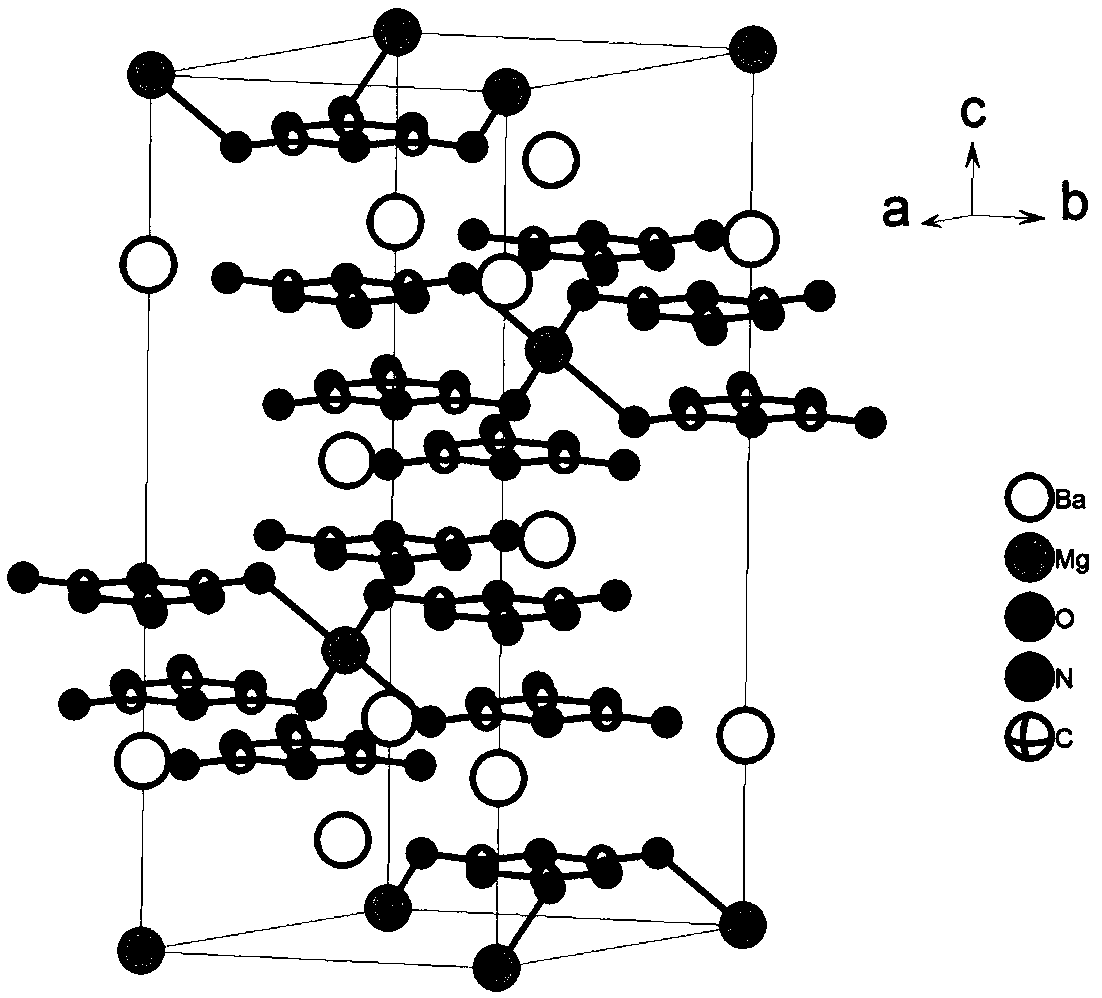

Barium magnesium cyanurate birefringent crystals for ultraviolet visible wavebands and preparation method and application of crystals

A technology of birefringent crystals and barium cyanurate, which is applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of crystal quality, crystal deliquescence, low permeability, etc., and achieve easy storage and polishing , easy-to-grow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, adopt high temperature melt spontaneous crystallization method to prepare Ba 2 Mg(C 3 N 3 o 3 ) 2 Crystal:

[0046] Weigh 4.166 g of BaCl 2 , 0.952 g MgCl 2 and 4.866 grams of KCNO (i.e. BaCl 2 : MgCl 2 : KCNO=0.02mol: 0.01mol:0.06mol), after mixing evenly, put it into a quartz glass tube of Φ20mm×100mm, and evacuate to 10 -3 After that, it was packaged with an oxyhydrogen flame and placed in a tube-type growth furnace, slowly raised to 500°C, kept at a constant temperature for 72 hours, and slowly cooled to room temperature at a rate of 1°C / h, and the tube-type growth furnace was closed; after the quartz tube cooled Cut, can get colorless and transparent Ba 2 Mg(C 3 N 3 o 3 ) 2 crystals.

Embodiment 2

[0047] Embodiment 2, adopt crucible descending method to prepare Ba 2 Mg(C 3 N 3 o 3 ) 2 Crystal:

[0048] Weigh 8.332 grams of BaCl 2 , 1.904 g MgCl 2 and 9.732 grams of KCNO (BaCl 2 : MgCl 2 : KCNO=0.04mol:0.02mol:0.12mol), after mixing evenly, put it into a quartz glass tube of Φ25mm×200mm, and evacuate to 10 -3 After that, it was packaged with an oxyhydrogen flame and placed in a tubular growth furnace, slowly raised to 400°C to react the raw materials in solid state for 96 hours, then the tubular growth furnace was closed, and the obtained product was washed repeatedly with methanol to remove the by-product KCl, dried and ground Crushed to get Ba 2 Mg(C 3 N 3 o 3 ) 2 powder. Will Ba 2 Mg(C 3 N 3 o 3 ) 2 Put the powder into a quartz glass tube of Φ25mm×200mm, and evacuate to 10 -3 After Pa, it is packaged with an oxyhydrogen flame and placed in a crystal growth furnace, and slowly raised to 500°C. After the raw materials are completely melted, the growt...

Embodiment 3

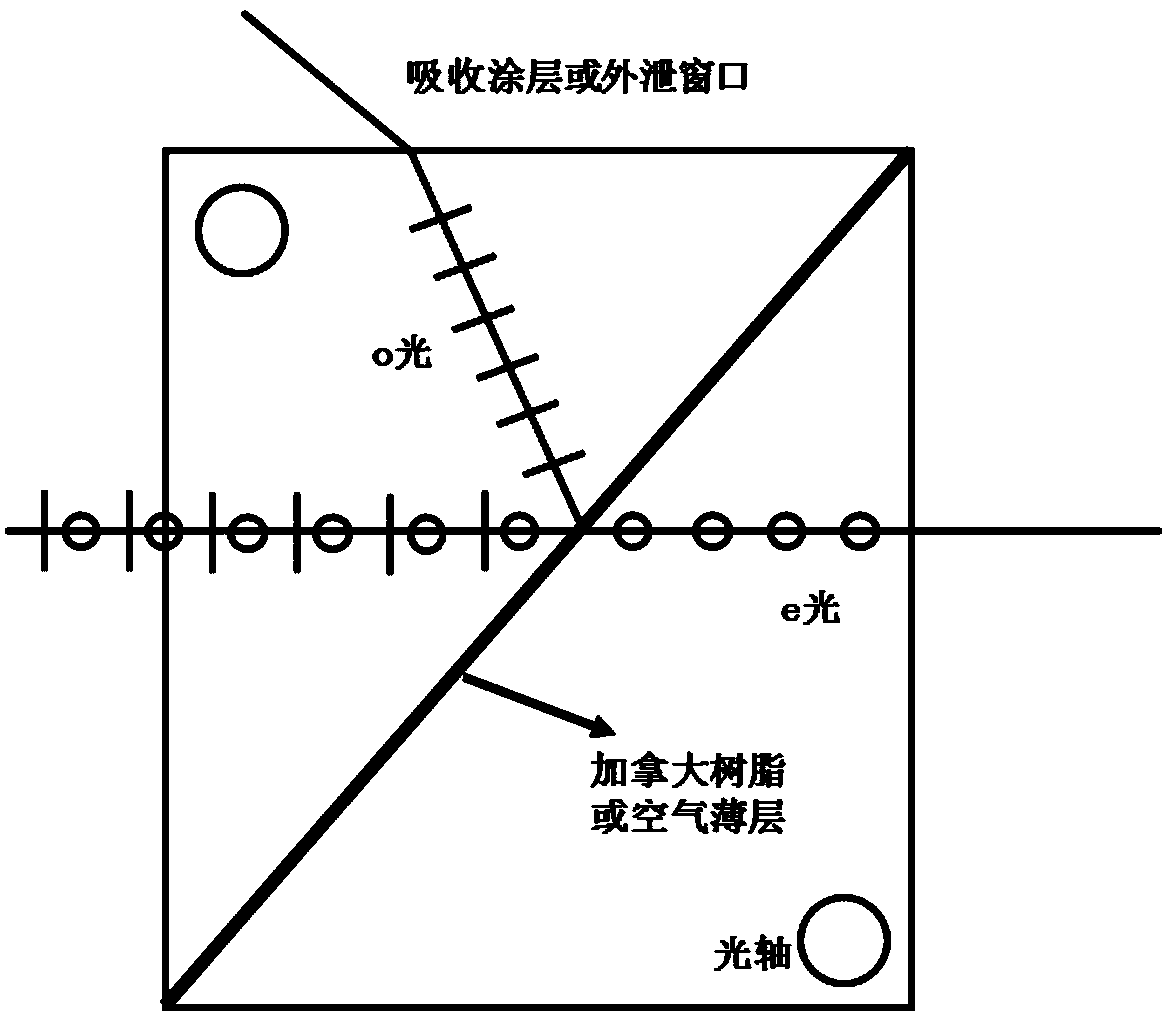

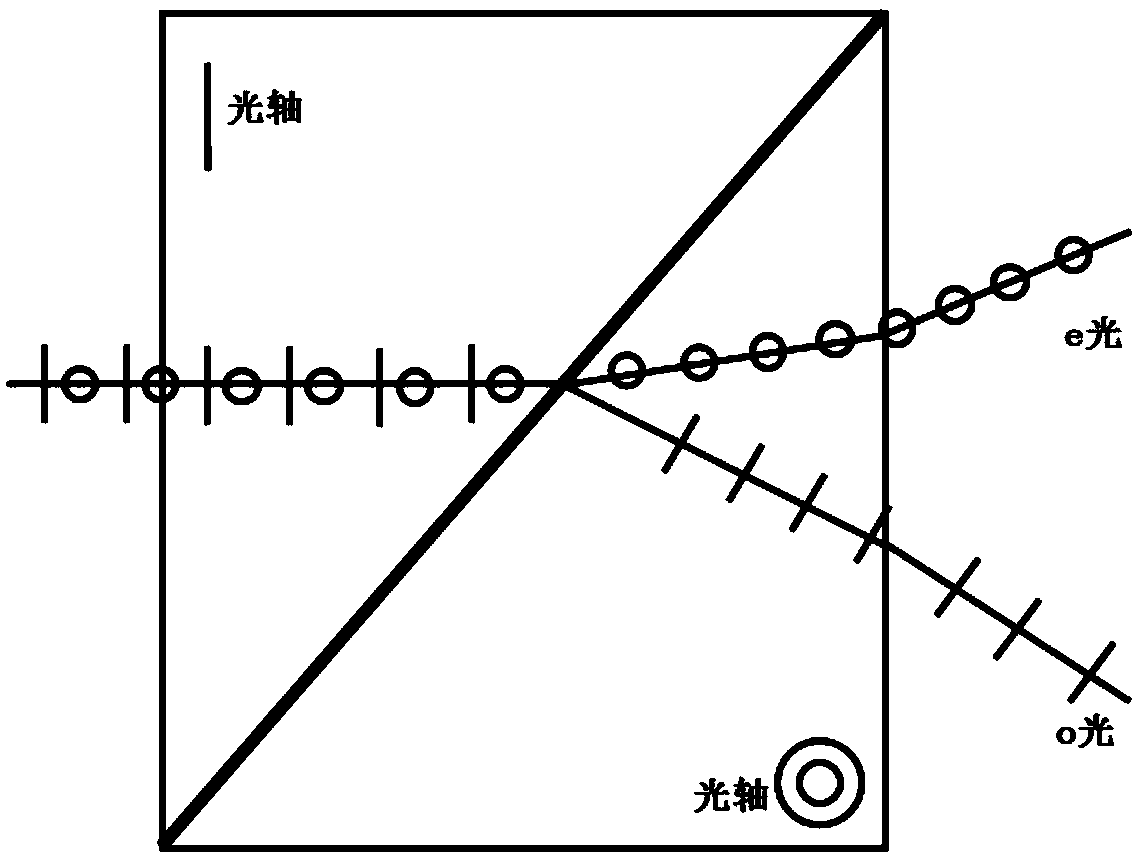

[0050] Embodiment 3, using the Ba of the present invention for the ultraviolet-visible band 2 Mg(C 3 N 3 o 3 ) 2 Birefringent crystals make Glan-type prisms:

[0051] Use Ba 2 Mg(C 3 N 3 o 3 ) 2 Crystals - Canadian resin (or air thin layer) - Ba 2 Mg(C 3 N 3 o 3 ) 2 The crystal constitutes a Glan-type prism ( figure 2 ), crystal n e o. When the incident light is incident perpendicular to the end face of the prism, neither the o-ray nor the e-ray will be deflected, and the incident angle on the inclined plane is equal to the angle between the inclined plane of the prism and the right-angled plane. During production, the angle between the oblique surface of the prism and the right-angled surface is greater than the critical angle of the o-ray on the glued surface, so that the o-ray will be totally reflected on the glued surface, and will be absorbed by the coating on the right-angled surface of the prism or leak out through the o-ray The window leaks out, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com