CHA type heteroatomic metal aluminum phosphate molecular sieve and premolding synthetic method

A metalloaluminophosphate and molecular sieve technology, which is applied in the direction of molecular sieve compounds, molecular sieve characteristic aluminum phosphate, molecular sieve catalysts, etc., can solve the problems of raw material waste, environmental pollution, etc., and achieve the effect of less usage, performance maintenance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

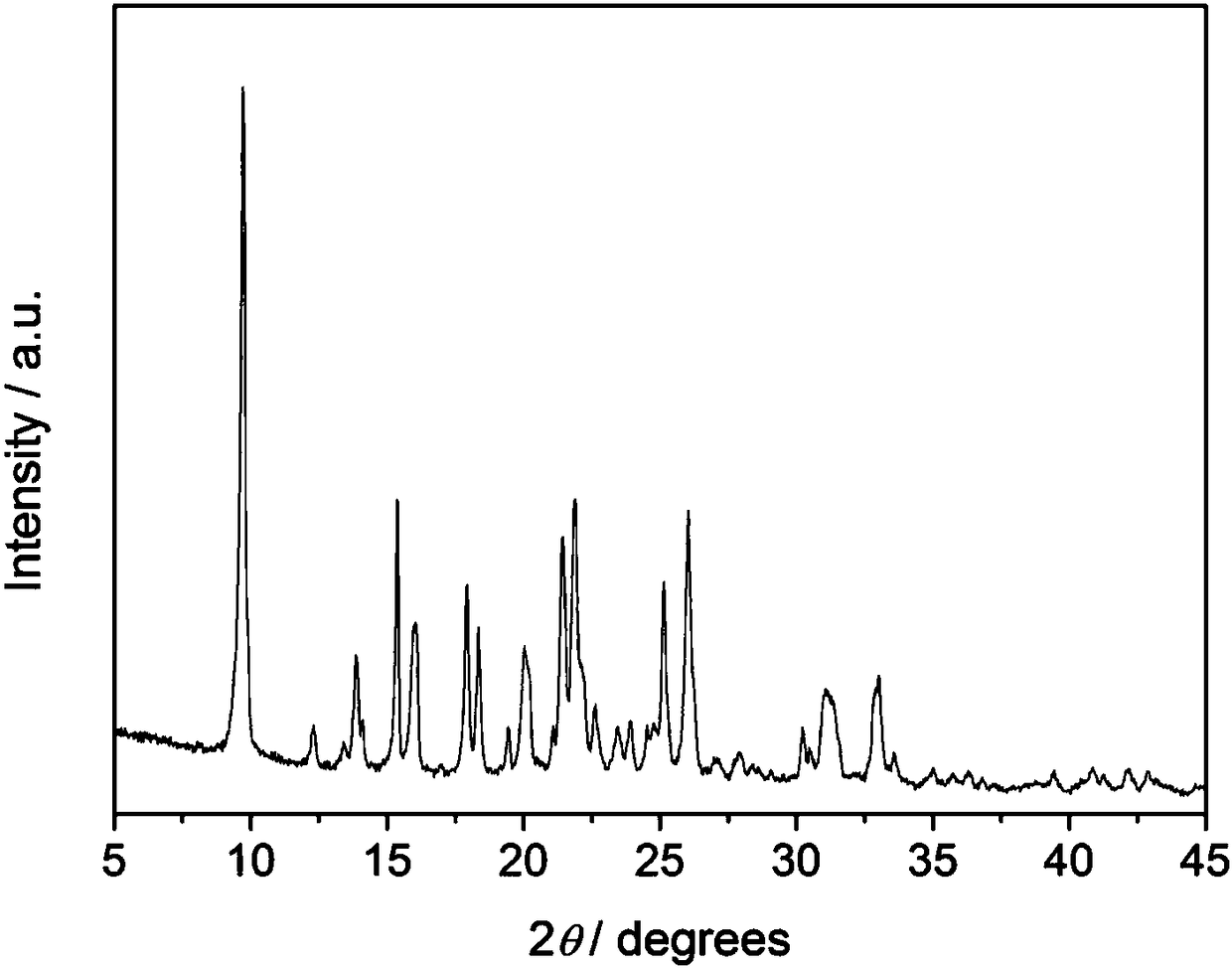

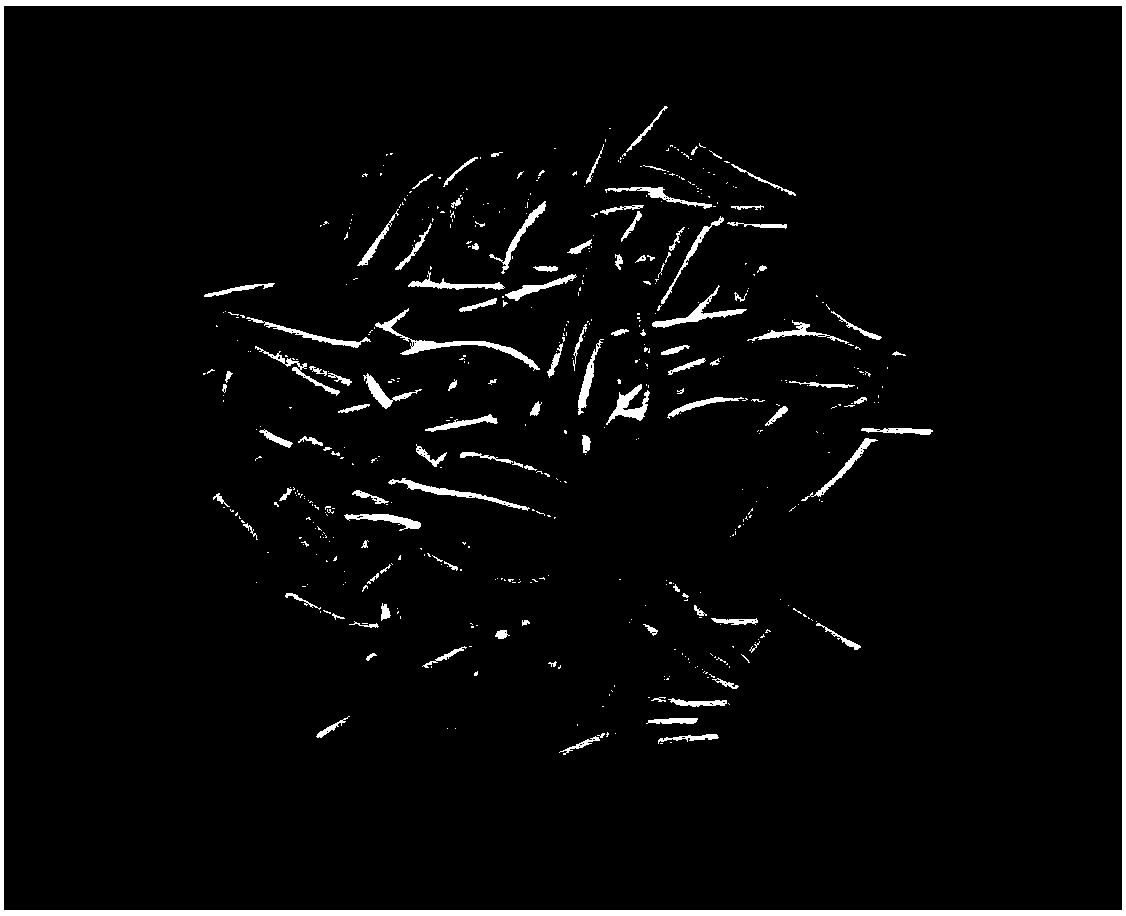

[0041] 17.35g pseudo-boehmite (78.6wt%Al 2 o 3 ) in a 250ml beaker, add 95.39g of deionized water, stir at room temperature for 30 minutes, add 36.98g of phosphoric acid with a concentration of 85wt%, stir at room temperature for 3 hours, add 1.76g of zinc acetate and stir for 30 minutes, add 6.01g of phosphoric acid 40wt% hydrofluoric acid, continue stirring for 30 minutes, add 7.68g of N-methylimidazole (1-mim), stir until uniform and evaporate to dryness at 90°C to obtain dry glue. The above dry glue is extruded into a cylindrical strip. Take 1g of molded dry glue and put it into a crystallization kettle with a polytetrafluoroethylene kettle lining, add 5g of 1-ethyl-3-methylimidazolium bromide ionic liquid into the crystallization kettle, and crystallize at 170°C for 7 sky.

[0042] After the crystallization, the synthesis kettle was cooled to room temperature, and the crystallized product was washed with deionized water and dried at 80° C. to obtain a shaped molecular ...

Embodiment 2

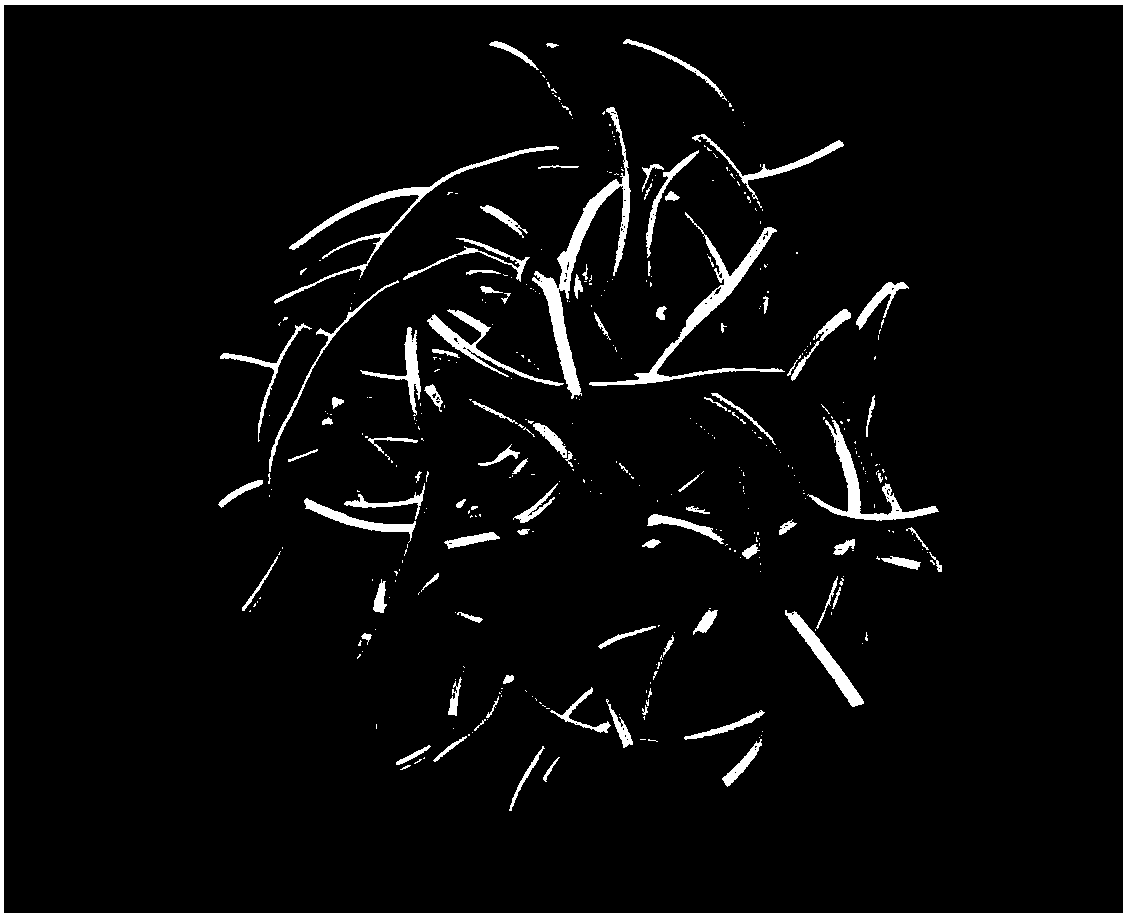

[0044] 17.35g pseudo-boehmite (78.6wt%Al 2 o 3 ) is placed in a 250ml beaker, add 129.23g deionized water, stir at room temperature for 30 minutes, add 66.35g of phosphoric acid with a concentration of 85wt% and 7.69g of ammonium dihydrogen phosphate with a purity of 99%, after stirring at room temperature for 3 hours, add Stir 0.06g of zinc acetate for 30 minutes, add 0.6g of 40wt% hydrofluoric acid, continue stirring for 30 minutes, add 32.92g of N-methylimidazole (1-mim), stir until uniform and evaporate at 110°C To dry to obtain dry glue. Extrude the above dry glue into clover strips. Take 1g of molded dry glue and put it into a crystallization kettle with a polytetrafluoroethylene kettle lining, add 10g of 1-ethyl-3-methylimidazolium bromide ionic liquid into the crystallization kettle, and crystallize at 230°C for 7 sky.

[0045] After the crystallization, the crystallization kettle was cooled to room temperature, and the crystallized product was washed with deionize...

Embodiment 3

[0047] 17.35g pseudo-boehmite (78.6wt%Al 2 o 3 ) in a 250ml beaker, add 44.23g of deionized water, stir at room temperature for 30 minutes, add 9.25g of phosphoric acid with a concentration of 85wt%, stir at room temperature for 3 hours, add 29.33g of zinc acetate and stir for 30 minutes, add 18.04g of phosphoric acid 40wt% of hydrofluoric acid and 1.49g of ammonium fluoride with a purity of 99%. After stirring for 30 minutes, add 1.1g of N-methylimidazole (1-mim), stir until uniform and evaporate to Dry to obtain dry glue. The above dry glue is extruded into a cylindrical strip. Take 1g of molded dry glue and put it into a crystallization kettle with a polytetrafluoroethylene kettle lining, add 5g of 1-ethyl-3-methylimidazolium bromide ionic liquid into the crystallization kettle, and crystallize at 230°C for 1 sky.

[0048] After the crystallization, the crystallization kettle was cooled to room temperature, and the crystallized product was washed with deionized water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com