Manufacturing method of heat exchanger based on combination of vacuum hot melting and explosion cladding

A manufacturing method and heat exchanger technology, which are applied in the field of heat exchangers, can solve problems such as heat exchangers that have not yet been consulted, and achieve the effects of low cost, stable operation, and guaranteed sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

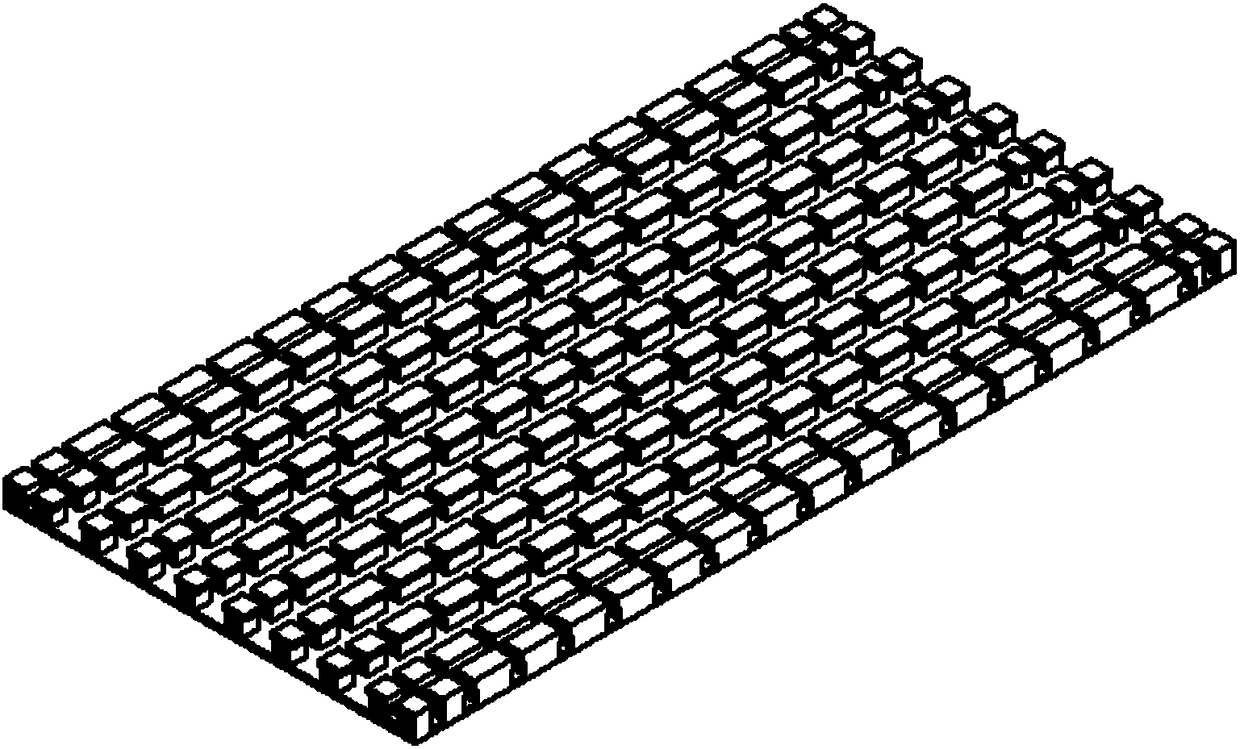

[0045] Step (1) see figure 1 Customized slotted tungsten plate, which can be micro-machined according to the needs of the slot type;

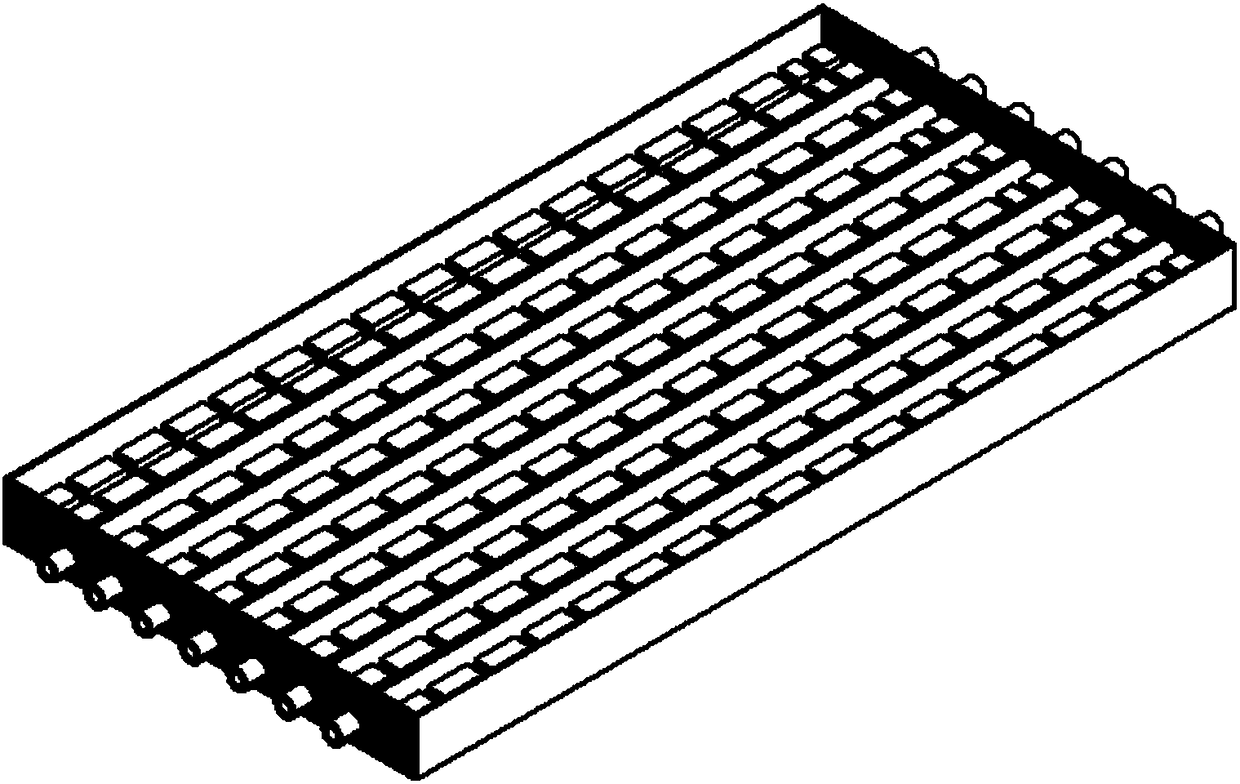

[0046] Step (2) Polish the front and back of the tungsten plate and its surroundings with sandpaper to make the surface of the tungsten plate smooth and smooth, then scrub the groove surface with alcohol, and then put the tungsten plate into a special mold, such as figure 2 ;

[0047] Step (3) preset the stainless steel tube on the tungsten plate;

[0048] Step (4) Put the copper block (copper plate) in the mold, that is, on the tungsten plate and the stainless steel tube, and put them into the high-temperature furnace together;

[0049]Step (5) Start the vacuum high-temperature furnace and heat it to between 1083.4°C and 1300°C. The copper is fully melted, but the stainless steel tube and tungsten are not melted. Part of the molten copper flows into the tungsten tank, and at the same time immerses the stainless steel pipe. Under the therma...

Embodiment 2

[0055] Step (1) see figure 1 Customized slotted tungsten plate, which can be micro-machined according to the needs of the slot type;

[0056] Step (2) Polish the front and back of the tungsten plate and its surroundings with sandpaper to make the surface of the tungsten plate smooth and smooth, then scrub the groove surface with alcohol, and then put the tungsten plate into a special mold, such as figure 2 ;

[0057] Step (3) preset the stainless steel tube on the tungsten plate at a certain distance, such as figure 2 ;

[0058] Step (4) Put the copper block (copper plate) in a special high-temperature-resistant container, start the high-temperature furnace, and heat until the copper is fully melted;

[0059] Step (5) Take out the container containing the copper liquid from the high-temperature furnace with special equipment, and immediately cast it on the tungsten plate. The copper liquid fully flows into the groove gap of the tungsten plate. , to achieve the initial co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com