Robot big cover plate and preparation process thereof

A preparation process and robot technology, applied in the field of metal materials, can solve problems such as many cracks, poor elongation, and complex aluminum alloys, and achieve the effects of refining grains, improving comprehensive performance, and eliminating segregation of components in the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

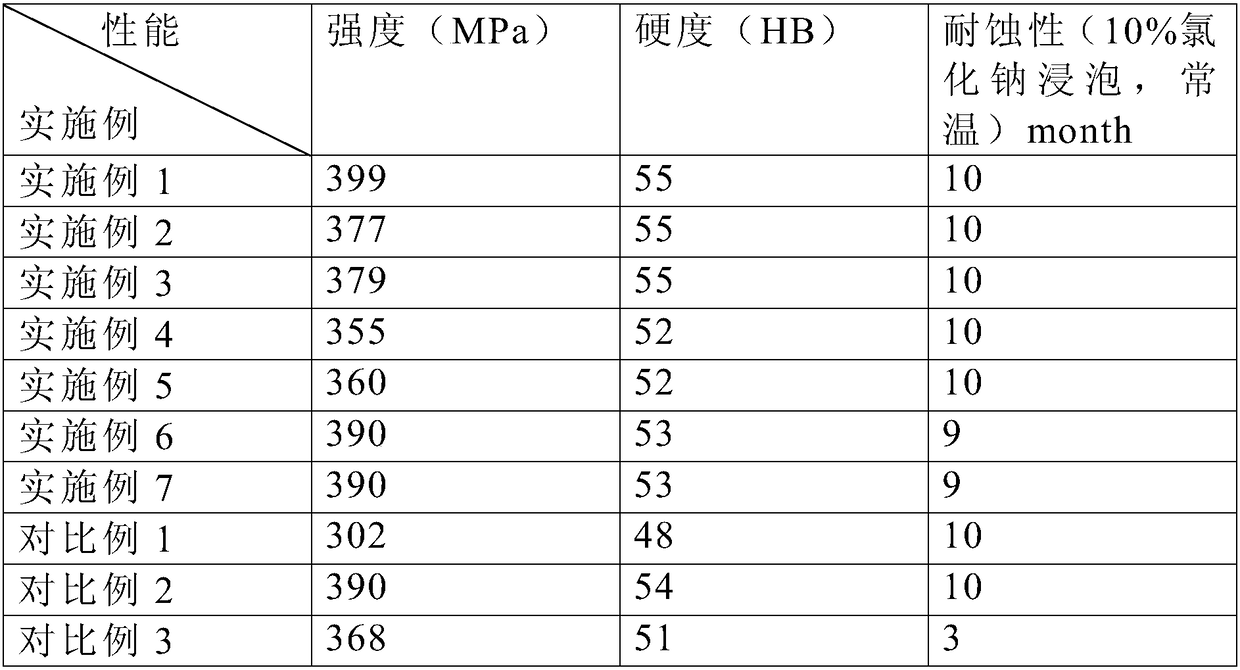

Examples

Embodiment 1

[0034] Ingredients: Weigh raw materials according to the composition and mass percentage of the above-mentioned large cover plate, including Fe: 0.4-0.8%, Si: 0.5-0.7%, Ti: 0.02-0.04%, Mg: 0.05-0.09%, Be: 0.01- 0.03%, the balance is Al and impurities, wherein the impurities include H<0.004%, O<0.006%. The raw materials are smelted and cast into aluminum alloy plates.

[0035] Heat treatment: The aluminum alloy plate is first subjected to progressive normalizing treatment, specifically: first heat the aluminum alloy plate to 420°C and keep it for 7 minutes, then heat the aluminum alloy plate to 535°C at a heating rate of 2°C / s and keep it 3min; after cooling, perform tempering treatment, the temperature of tempering treatment is 325°C, and keep for 50min; then perform homogenization annealing treatment, specifically: cool the tempered aluminum alloy plate to room temperature, and immerse it in the prepared salt solution , heated to 250°C, kept for 1.5h, and naturally cooled to...

Embodiment 2

[0039] Ingredients: Weigh raw materials according to the composition and mass percentage of the above-mentioned large cover plate, including Fe: 0.4%, Si: 0.5%, Ti: 0.02%, Mg: 0.05%, Be: 0.01%, and the balance is Al and impurities. The impurities include H<0.004%, O<0.006%. The raw materials are smelted and cast into aluminum alloy plates.

[0040]Heat treatment: The aluminum alloy plate is first subjected to progressive normalizing treatment, specifically: first heat the aluminum alloy plate to 420°C and keep it for 7 minutes, then heat the aluminum alloy plate to 535°C at a heating rate of 2°C / s and keep it 3min; after cooling, perform tempering treatment, the temperature of tempering treatment is 325°C, and keep for 50min; then perform homogenization annealing treatment, specifically: cool the tempered aluminum alloy plate to room temperature, and immerse it in the prepared salt solution , heated to 250°C, kept for 1.5h, and naturally cooled to room temperature, wherein th...

Embodiment 3

[0044] Ingredients: Weigh raw materials according to the composition and mass percentage of the above-mentioned large cover plate, including Fe: 0.8%, Si: 0.7%, Ti: 0.04%, Mg: 0.09%, Be: 0.03%, and the balance is Al and impurities. The impurities include H<0.004%, O<0.006%. The raw materials are smelted and cast into aluminum alloy plates.

[0045] Heat treatment: The aluminum alloy plate is first subjected to progressive normalizing treatment, specifically: first heat the aluminum alloy plate to 420°C and keep it for 7 minutes, then heat the aluminum alloy plate to 535°C at a heating rate of 2°C / s and keep it 3min; after cooling, perform tempering treatment, the temperature of tempering treatment is 325°C, and keep for 50min; then perform homogenization annealing treatment, specifically: cool the tempered aluminum alloy plate to room temperature, and immerse it in the prepared salt solution , heated to 250°C, kept for 1.5h, and naturally cooled to room temperature, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com