Chlorination tail water recycling method and chlorination tail water recycling device

A chlorination tail and water recovery technology, which is applied to calcium carbide feed generators, petroleum industry, acetylene generators, etc., can solve the problems of unreasonable utilization of chlorination tail water, so as to eliminate the impact of odor, eliminate environmental impact, The effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The method for recycling chlorinated tail water provided by the present invention includes the following steps: S1: injecting chlorinated tail water into the calcium carbide slag slurry concentration tank through the tail water circulation pump; S2: adding trace free chlorine, sulfide Odor gases such as hydrogen and phosphine are reacted and solidified and separated by sedimentation; S3: the supernatant from the calcium carbide slag concentration tank flows into the supernatant tank through the potential difference; S4: the supernatant in the supernatant tank passes through the supernatant pump Sent into the washing and cooling tower; S5: The supernatant is washed and condensed in the washing and cooling tower, and then pumped into the acetylene generator through the slag water recycling pump to react with calcium carbide to produce acetylene gas. There is no need to add industrial water, the amount of water added is reduced, the utilization rate of water is improved, th...

Embodiment 2

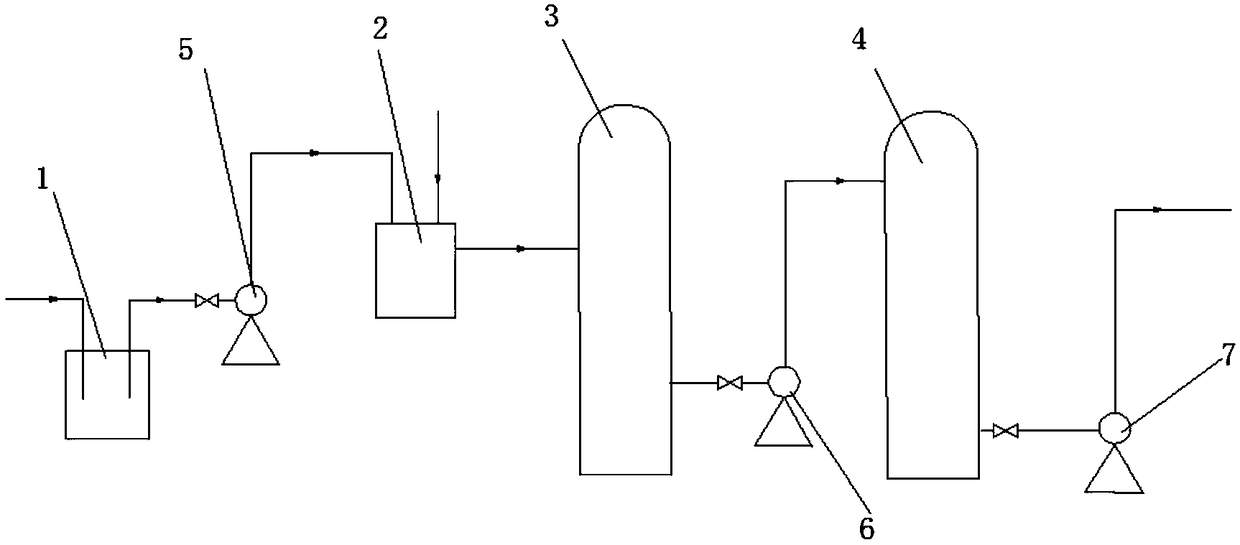

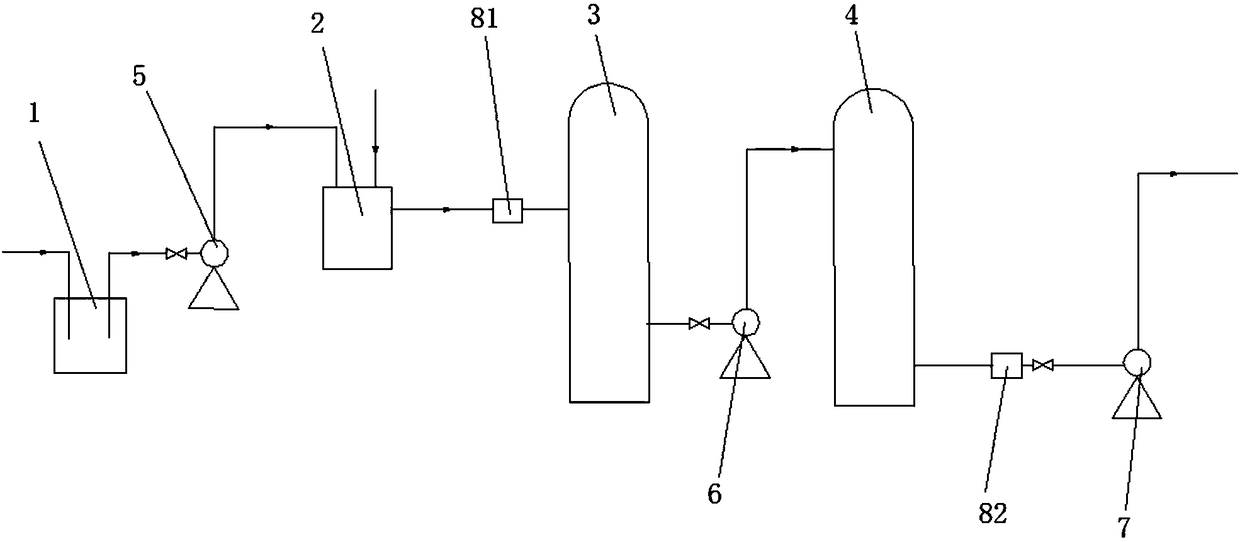

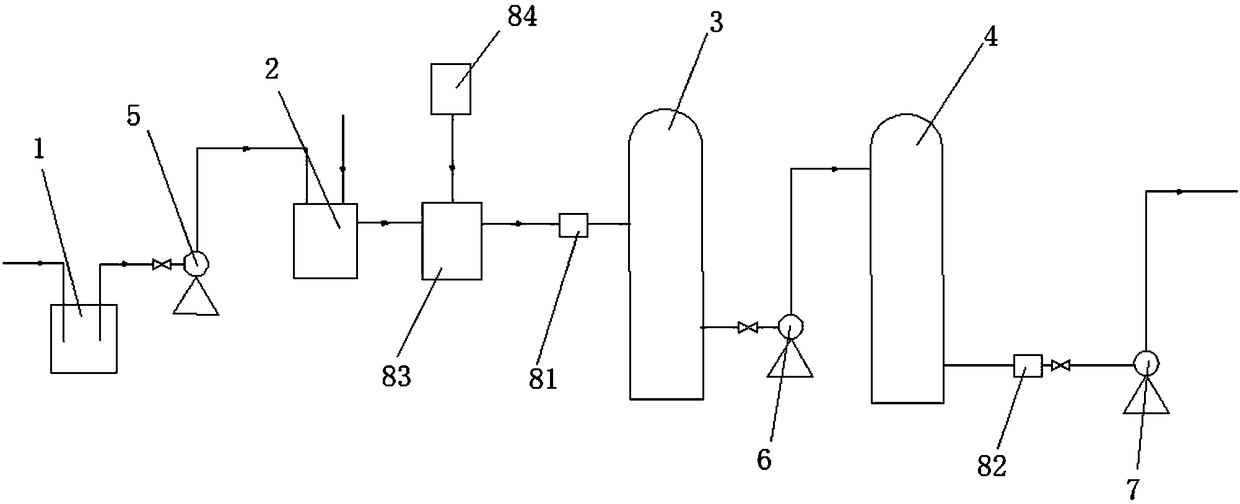

[0050] Such as figure 1 As shown in -4, the chlorinated tail water recovery and utilization device provided by Embodiment 2 of the present invention includes: a chlorinated tail water storage tank 1, a calcium carbide slag concentration tank 2, a supernatant tank 3 and a washing cooling tank connected in sequence through pipelines. Tower 4; a tail water circulation pump 5 is set between the chlorination tail water storage tank 1 and the calcium carbide slag slurry concentration tank 2; a supernatant liquid pump 6 is set between the supernatant liquid tank 3 and the washing cooling tower 4.

[0051] This scheme fully analyzes the properties of each trace impurity in the two waste waters, and uses the principle of redox to transform them into other stable substances through chemical reactions, turning waste water into profit. The specific principles are as follows:

[0052] h 2 S+NaClO=NaCl+S↓+H 2 o

[0053] 2H 3 P+3NaClO=3NaCl+2P↓+3H 2 o

[0054] The chlorinated tail wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com