Filling material for bone defect part caused after giant bone cell tumor removal operation and preparation method of filling material

A technology for giant cell tumor of bone and bone defect, which is applied in the field of medical engineering to achieve the effects of reducing corrosion rate, good biocompatibility, and inhibiting vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

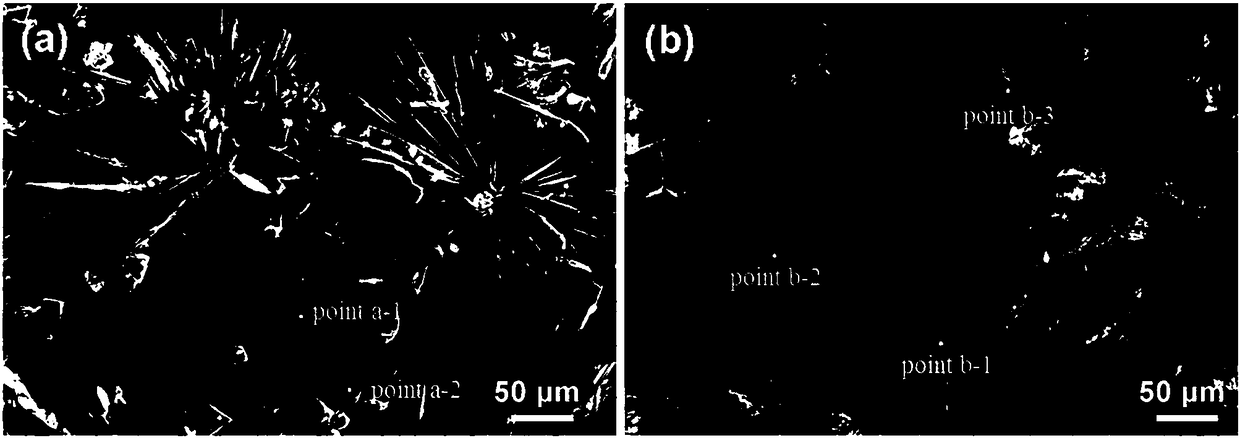

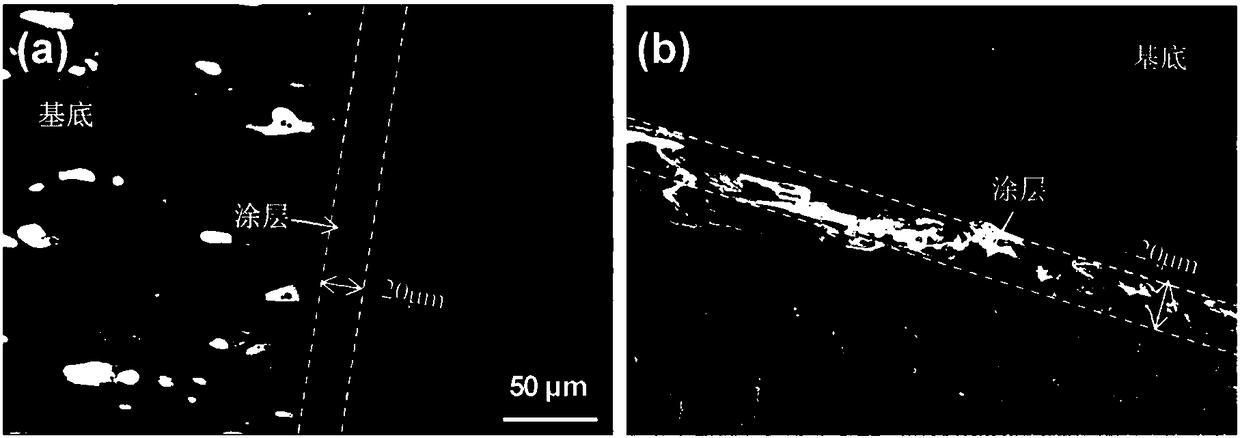

[0031] The magnesium-strontium alloy (Mg-1.5wt.%Sr) substrate was cut to a suitable size, polished on No. 220 sandpaper until there was no oxide layer, and then successively polished on 800-mesh alumina water-resistant sandpaper and 2000-mesh SiC water sandpaper. The polished magnesium alloy substrate was ultrasonically cleaned in acetone and alcohol for 30 minutes in sequence, washed with distilled water and dried for later use. Soak the sample in 0.1M potassium fluoride solution for 24 hours for fluorination pretreatment, then soak the pretreated magnesium-strontium alloy in a solution containing 60g / L NaNO 3 ,15g / LCa(H 2 PO 4 ) 2 ·H 2 O and 20mL / LH 2 o 2 In the phosphate mixture for 24 hours, a calcium-phosphorus coating is formed on the surface. Soak the magnesium-strontium alloy substrate with calcium-phosphorus coating in 5mL of 10 -2 In the μM zoledronic acid solution, incubate at 37°C for 24 hours to form a zoledronic acid coating on the surface of the magnesium...

Embodiment 2

[0033] Cut the magnesium-strontium alloy (Mg-1.5wt.%Sr) substrate to a suitable size, polish it on No. 220 sandpaper until there is no oxide layer, and then successively polish it on 800 mesh alumina water-resistant sandpaper and 2000 mesh SiC water sandpaper. The polished magnesium alloy substrate was ultrasonically cleaned in acetone and alcohol for 30 minutes in sequence, washed with distilled water and dried for later use. Soak the sample in 0.1M potassium fluoride solution for 24 hours for fluorination pretreatment, then soak the pretreated magnesium strontium alloy in 60g / L NaNO 3 ,15g / L Ca(H 2 PO 4 ) 2 ·H 2 O and 20mL / L H 2 o 2 After 24 hours in the middle, a calcium phosphorus coating is formed on the surface. Soak calcium-phosphorus-coated magnesium-strontium alloy in 5mL of 10 -2 In the μM sodium pamidronate solution, incubate at 37°C for 24 hours, and form a bisphosphonate coating on the surface of the magnesium alloy substrate through the chelation of sodium...

Embodiment 3

[0035] Cut the magnesium-strontium alloy (Mg-1.5wt.%Sr) substrate to a suitable size, polish it on No. 220 sandpaper until there is no oxide layer, and then successively polish it on 800 mesh alumina water-resistant sandpaper and 2000 mesh SiC water sandpaper. The polished magnesium alloy substrate was ultrasonically cleaned in acetone and alcohol for 30 minutes in sequence, washed with distilled water and dried for later use. Soak the sample in 0.1M potassium fluoride solution for 24 hours for fluorination pretreatment, then soak the pretreated magnesium strontium alloy in 60g / L NaNO 3 ,15g / L Ca(H 2 PO 4 ) 2 ·H 2 O and 20mL / L H 2 o 2 After 24 hours in the middle, a calcium phosphorus coating is formed on the surface. Soak calcium-phosphorus-coated magnesium-strontium alloy in 5mL of 10 -2 Incubate in μM sodium allenphosphate solution at 37°C for 24 hours to form a bisphosphonate coating on the surface of the magnesium alloy substrate through the chelation of sodium all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com