Integrated heat pipe heat dissipation device

A cooling device and an integrated technology, applied in the field of heat transfer, can solve the problems that the life of the heat pipe system is easy to cause risks, the problem of corrosion protection cannot be completely solved, and the reliability of the heat pipe system is reduced, so as to shorten the flow path of the boundary layer flow and enhance the air quality. Effect of permeable, high-efficiency heat transfer surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

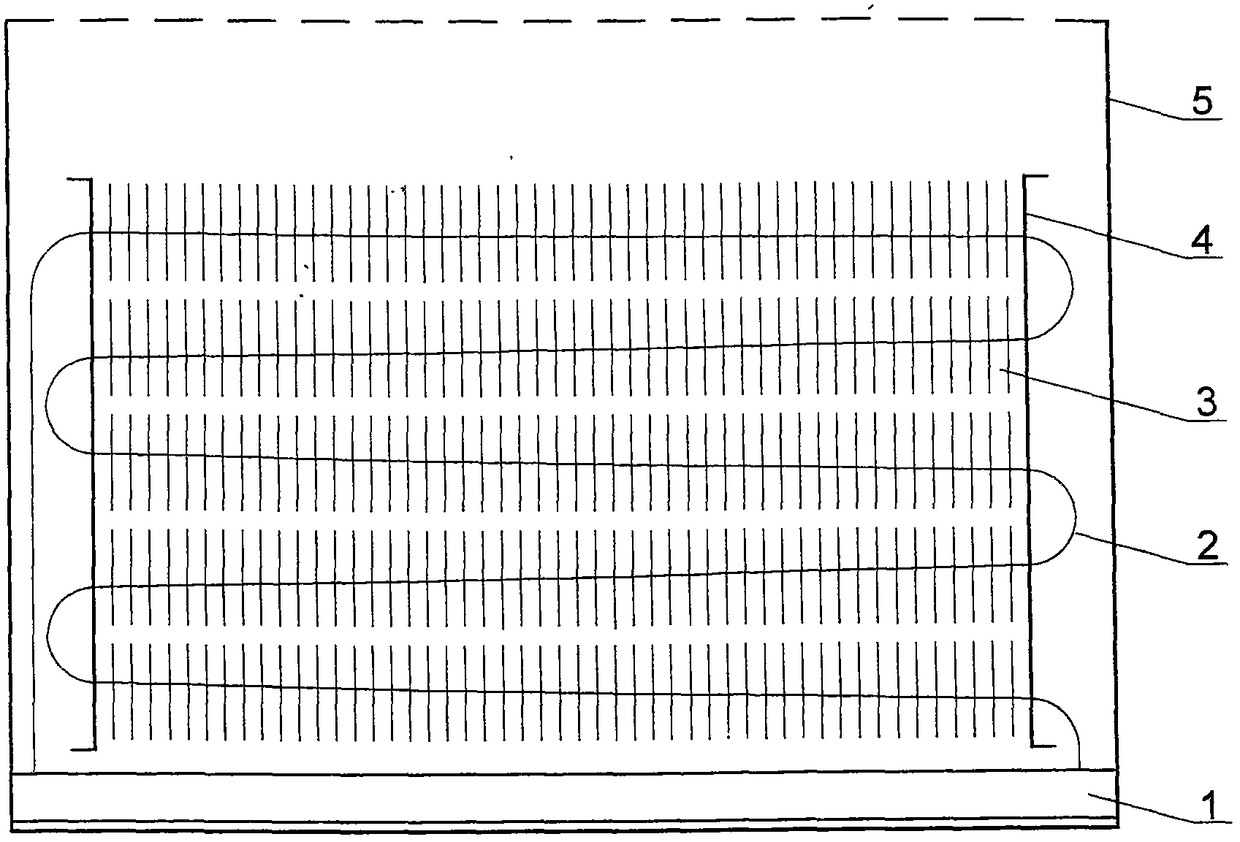

[0024] Such as figure 1 As shown, an integrated heat pipe cooling device provided by the present invention includes: an evaporator (1), a heat pipe (2), a cooling fin (3), a fixed end plate (4) and an outer cover (5); the heat pipe (2) It is made by bending the whole continuous pipe through a loop, and there is a certain angle between the transverse axis of the heat pipe and the horizontal direction. The cooling fins (3) are small rectangular fins, which are tightly fixed on the heat conducting pipes (2) through expansion tubes. The fixed end plate (4) is installed on the curved end of the heat pipe (2), parallel to the heat dissipation fins (3), and is used for assembling and forming the heat dissipation inner core and installing and fixing the outer cover.

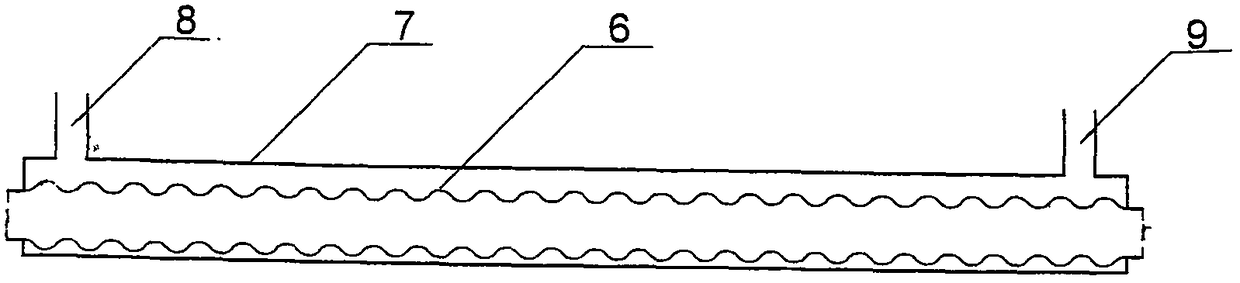

[0025] Such as figure 2 or figure 1 As shown: the evaporator is composed of a sealed cavity composed of a heat source tube (6) and an evaporator shell (7). The evaporator shell (7) is provided with a steam outlet (8)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com