Single and double hanging point conversion type lifting device

A hoisting device and transforming technology, which is applied to portable hoisting devices, hoisting devices, clockwork mechanisms, etc., can solve the problems of heavy equipment, complicated operation, and many operation links of the hoisting mechanism, and achieve the reduction of equipment weight, The overall structure is simple and the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

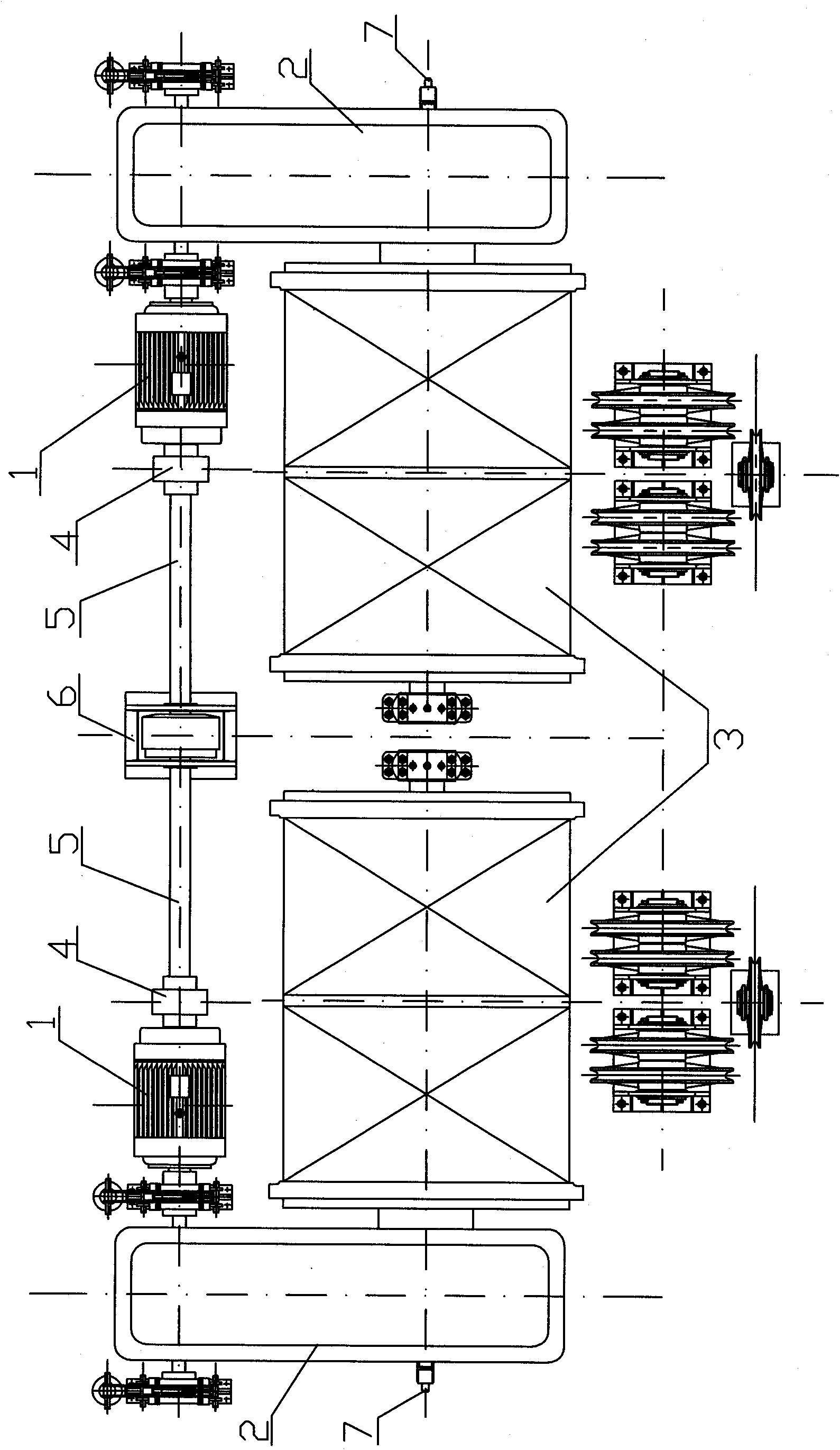

[0010] As shown in the figure, the single-double lifting point conversion type lifting device described in the present invention includes a working motor 1, a reducer 2 driven by the working motor 1 and a reel 3 for winding a wire rope; The two sets of 2 and reel 3 are symmetrically arranged; the other end of the output shaft of the working motor 1 is connected with a synchronous shaft 5 through a coupling 4, and the two synchronous shafts 5 are connected by an electromagnetic clutch 6; The outside of the output shaft of the reducer 2 at the end of the reel 3 is respectively provided with a head indicator and a position control device 7, and the head indicator and position control device 7 includes an absolute value encoder, a stroke limit switch and a display instrument; The head indication and position control devices 7 on the output shafts of the two reducers 2 are arranged symmetrically.

[0011] Two sets of lifting mechanisms consisting of working motor 1, reducer 2 and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com