Bamboo fiber/polylactic acid composite material and preparation method thereof

A composite material and bamboo fiber technology, applied in the field of bamboo fiber/polylactic acid composite material and its preparation, can solve the problems of bamboo fiber not easy to disperse, poor compatibility, black spots on the surface, etc., and achieve excellent surface appearance, phase The effect of improved capacitance and improved hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

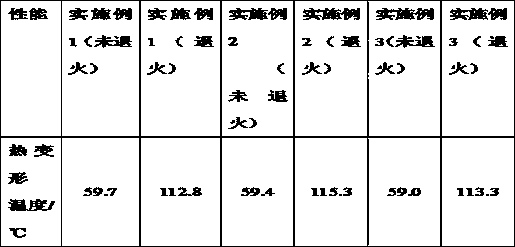

Examples

Embodiment 1

[0043] Weigh respectively 600g of polylactic acid, 100g of talcum powder with a particle size of 2 microns, 30g of 20 mesh modified bamboo fiber, 20g of toughening agent, 1g of coupling agent, 1g of antioxidant, 2g of auxiliary antioxidant, 2g of lubricant, Nucleating agent 2g, anti-floating agent 1g and anti-hydrolysis agent 5g;

[0044] The preparation steps of modified bamboo fiber:

[0045] a. the bamboo fiber is alternately washed 2 times with sodium hydroxide solution and water, and dried after washing;

[0046] b. According to the mass ratio of 1:10, add the dried bamboo fiber into the polyethylene glycol solution with a mass fraction of 5% and add liquid paraffin wax with a mass of 5% of the bamboo fiber, heat up to 100°C, stir mechanically for 20 minutes, and add sixteen Alkyl sodium sulfate, the addition is 10% of the liquid paraffin mass, stirred at 800r / min to obtain a mixed solution;

[0047] c. Add 1% citric acid by mass of the mixed solution to the mixed solut...

Embodiment 2

[0060] Weigh respectively 700g of polylactic acid, 200g of talc powder with a particle size of 3 microns, 100g of modified bamboo fiber of 100 mesh, 100g of toughening agent, 2g of coupling agent, 2g of antioxidant, 4g of auxiliary antioxidant, 4g of lubricant, Nucleating agent 8g, anti-floating agent 2g and anti-hydrolysis agent 10g;

[0061] The preparation steps of modified bamboo fiber:

[0062] a. the bamboo fiber is alternately washed 2 times with sodium hydroxide solution and water, and dried after washing;

[0063] b. According to the mass ratio of 1:10, add the dried bamboo fiber into the polyethylene glycol solution with a mass fraction of 5% and add liquid paraffin wax with a mass fraction of 7% of the bamboo fiber, raise the temperature to 110°C, stir mechanically for 25 minutes, and add sixteen Alkyl sodium sulfate, the addition is 15% of the liquid paraffin quality, stirred at a speed of 900r / min to obtain a mixed solution;

[0064] c. Add 2% citric acid of the...

Embodiment 3

[0077] Weigh respectively 800g of polylactic acid, 300g of talc powder with a particle size of 4 microns, 150g of 200 mesh modified bamboo fiber, 150g of toughening agent, 3g of coupling agent, 3g of antioxidant, 6g of auxiliary antioxidant, 5g of lubricant, Nucleating agent 10g, anti-floating agent 3g and anti-hydrolysis agent 30g;

[0078] The preparation steps of modified bamboo fiber:

[0079] a. Bamboo fibers are washed 3 times alternately with sodium hydroxide solution and water, and dried after washing;

[0080] b. According to the mass ratio of 1:10, add the dried bamboo fiber into the polyethylene glycol solution with a mass fraction of 5% and add liquid paraffin wax with a mass fraction of 10% of the bamboo fiber, raise the temperature to 120°C, stir mechanically for 30 minutes, and add sixteen Alkyl sodium sulfate, the addition is 20% of the liquid paraffin quality, stirred at a speed of 1000r / min to obtain a mixed solution;

[0081] c. Add 3% citric acid of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com