A preparation method and production device of battery-grade iron phosphate

An iron phosphate and battery-level technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of inability to obtain stable products, blockage of undissolved solids, high local concentration, etc., to eliminate quality differences and artificial interference factors, reduced back-mixing, and short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

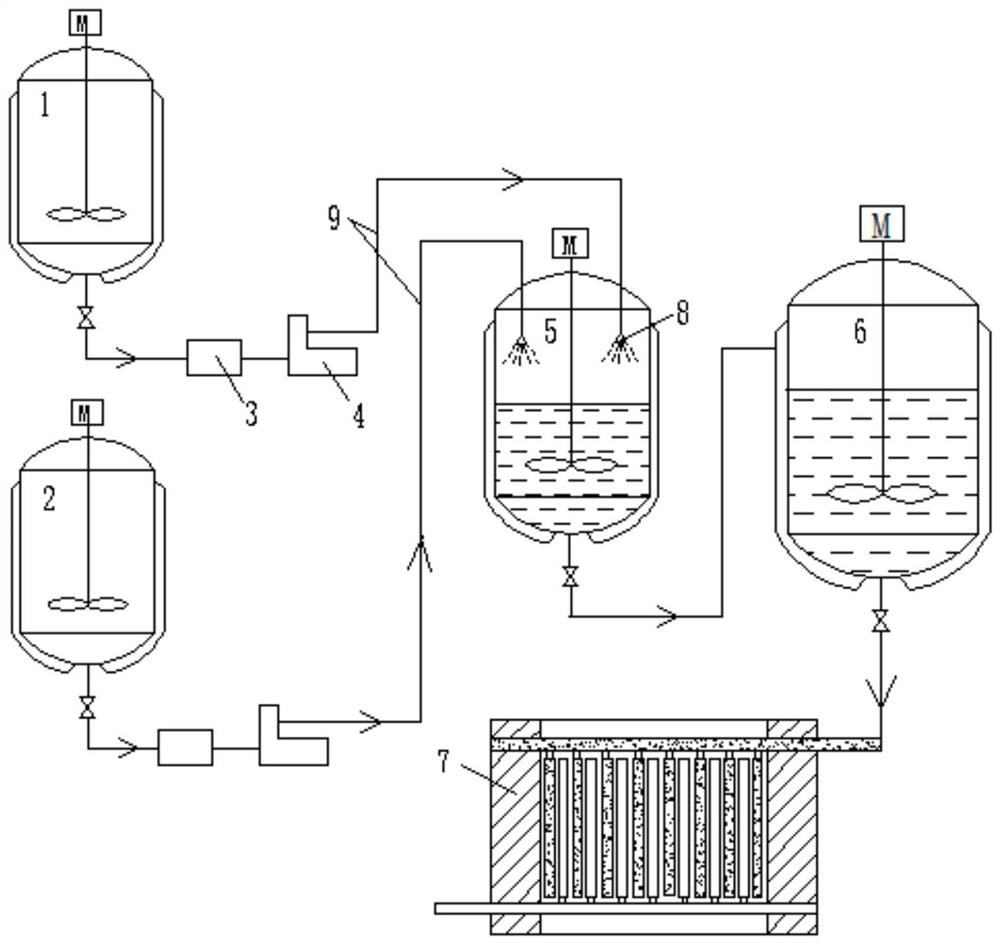

[0028] The preparation method of ferric phosphate of the present invention, comprises the steps:

[0029] Step a, preparation of iron salt solution: iron source is dissolved in pure water of 15 ℃-40 ℃ to make iron salt solution, the mass percentage concentration of ferrous ion in the solution is 5%-8% (wt), the solution after dissolving The pH value is 2.0-4.0. The iron source is one of ferrous sulfate, ferrous chloride, ferrous nitrate or ferrous oxalate.

[0030] Iron powder can also be placed in sulfuric acid, hydrochloric acid, nitric acid or oxalic acid solution to react to obtain iron salt solution.

[0031] Step b. Prepare phosphorus source solution: add phosphorus source into pure water at a temperature of 20°C-35°C, dissolve and add oxidant and surfactant, and stir evenly to prepare phosphorus source solution. The pH of the solution was 7-8.5.

[0032] The phosphorus source is one of sodium phosphate, potassium phosphate, disodium hydrogen phosphate, sodium dihydro...

Embodiment 1

[0042] In the phosphate storage tank of 1000L, add 235.0kg disodium hydrogen phosphate solid and 700.0kg pure water, after dissolving, add 70.8kg hydrogen peroxide (the concentration of hydrogen peroxide is 30%) and 2.0kg triethanolamine oleic acid soap, stir well and set aside , make phosphorus source solution, the concentration of phosphate ion in the solution is 15.60%. In another 2000L ferric salt storage tank, prepare 1200kg concentration of 14.0% ferrous chloride solution for subsequent use to make ferric salt solution, the concentration of iron ions in the solution is 6.17%.

[0043] Add 10kg of pure water to a 100L reactor, and use two metering pumps to add the filtered phosphorus source solution and iron salt solution to the reactor at the same time. The temperature of the feed liquid in the reactor is 57°C, and the phosphorus source solution The addition amount of the ferrous solution is 0.616kg / min, the addition amount of the ferrous solution is 0.984kg / min, and the...

Embodiment 2

[0046] Take a 1000L phosphate storage tank, add 256.0kg of disodium hydrogen phosphate solid, 700.0kg of pure water, 70.8kg of hydrogen peroxide (concentration is 30%) and 2.5kg of PEG-400, stir well and set aside to make phosphorus source solution , the concentration of phosphate ions in the solution is 16.64%. In another 2000L ferric salt storage tank, prepare 1200kg concentration of 14.0% ferrous chloride solution as ferric salt solution.

[0047] Add 40kg of pure water to a 250L reactor in advance, and then use two metering pumps to add the filtered phosphorus source and iron salt solution to the reactor at the same time. The pump is 0.616kg / min, the ferrous metering pump is 0.923kg / min, and the stirring speed is 300rpm. After the material in the kettle stays for 40 minutes, start to continuously extract the material, so that the output speed and the feeding speed are kept consistent. Collect the reaction liquid for 1 hour, press filter and wash, and obtain the iron phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com