Double-silk fibroin nerve graft

A silk fibroin and nerve transplantation technology, applied in the field of biomedical materials, can solve the problems of lack of flexibility and strength, poor mechanical properties of scaffolds, etc., and achieve the effect of improving mechanical properties, good mechanical properties, and good tissue compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

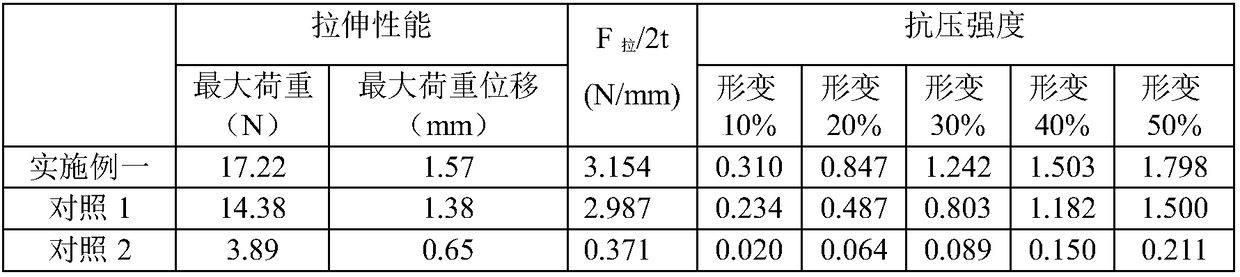

Embodiment 1

[0032] The preparation of double silk fibroin nerve graft described in embodiment 1 of the present invention

[0033] (1) The preparation of mulberry silk fibroin fiber: get mulberry silk, in 0.2% Na 2 CO 3 Boil in the solution to remove the outer sericin, repeat 3 times for 30 minutes each time, thoroughly wash with three-distilled water, and then place it in an ultra-clean bench to dry to obtain silk fibroin fiber.

[0034] (2) Preparation of tussah silk fibroin protein: get 25g tussah silk, put it in 1000ml0.2% Na 2 CO 3 Boil in the solution for 30 minutes each time, repeat 3 times, thoroughly wash with triple-distilled water, and then place it on a super-clean table to dry to obtain tussah silk fibroin.

[0035] Preparation of regenerated tussah silk fibroin protein: get 6 g of tussah silk fibroin protein prepared above and dissolve in 25 mL lithium thiocyanate solution (9mol / L) to obtain a brown solution. The dissolution temperature is 40° C., and the solution is packe...

Embodiment 2

[0039] The preparation of embodiment two control catheters

[0040] Referring to the method of Example 1, a catheter with silk fibroin skeleton and shell (control 1) was prepared.

[0041] The 3% regenerated tussah silk fibroin protein solution is concentrated to 5-10%, poured into a mold, and freeze-dried at -70°C to form a conduit. The obtained catheter was soaked in 60% ethanol for 12 hours to make it denatured, then soaked and washed with deionized water, and dried naturally to obtain a catheter with only tussah silk fibroin shell (control 2).

Embodiment 3

[0042] Example 3 Investigation of Cell Adhesion and Growth Performance

[0043] (1) Preparation of mulberry silk fibroin film: the mulberry silk fiber obtained in Example 1 (1) is dissolved in a ternary solvent system (anhydrous CaCl 2 : Anhydrous C 2 h 5 OH: triple distilled water = 1:2:8) to obtain a yellow transparent solution with a dissolution temperature of 73±2°C. The solution was placed in a cellulose tube (molecular weight cut-off: 12-14KD), and dialyzed with triple distilled water for 3 days. The dialyzed silk fibroin solution was poured into a petri dish, and placed in an ultra-clean bench to air dry. After being dried, it is peeled off to form a silk fibroin film.

[0044] (2) Preparation of tussah silk fibroin protein film: Pour the tussah silk fibroin protein solution dialyzed in Example 1 (2) into a petri dish, and put it in an ultra-clean table to blow air to dry. After drying, it is peeled off to form a tussah silk film.

[0045] (3) Cell culture: steril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com