Flue-curing method for flue-cured tobacco NC87 tobacco leaves

A technology of flue-cured tobacco varieties and curing methods, applied in the fields of tobacco, tobacco preparation, application, etc., which can solve the problems of reduced oil content, reduced aroma, and light color of tobacco leaves, and achieve a high aroma, high aroma quality, and low starch content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

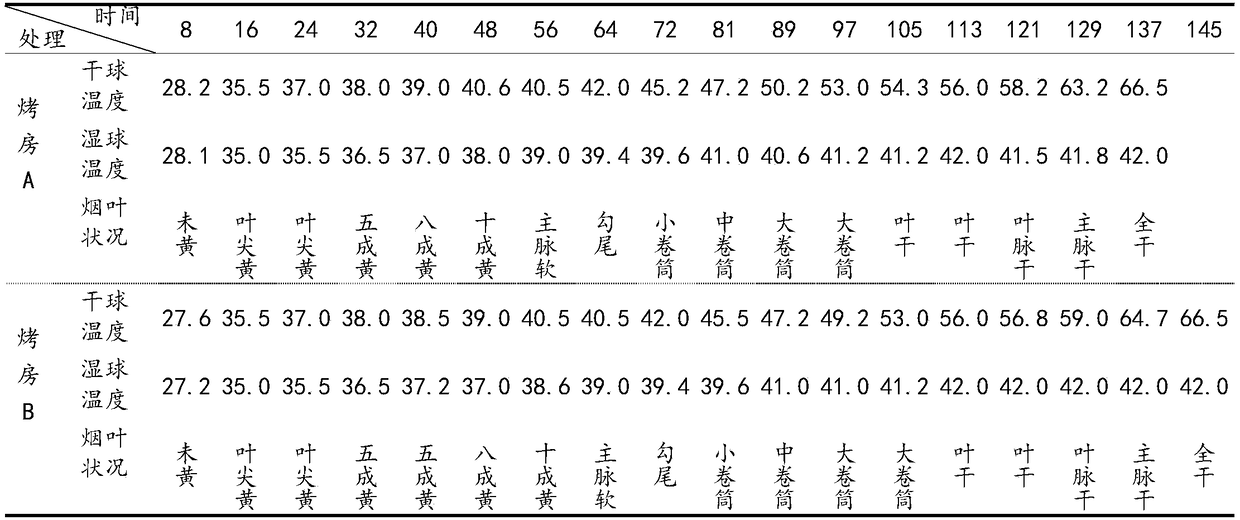

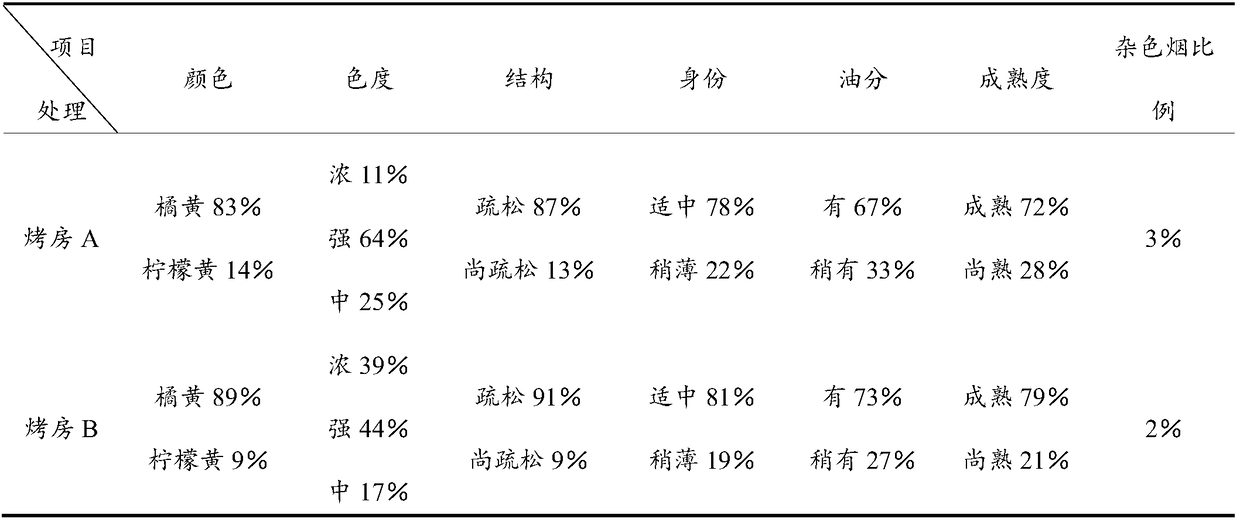

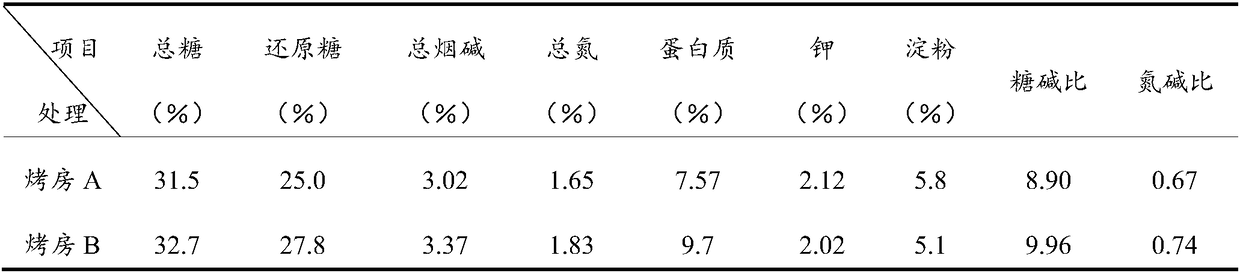

[0038] A method for curing tobacco leaves of a flue-cured tobacco variety Yunyan 87. The Yunyan 87 is planted in purple soil, and the leaf age in the middle part is 104 days. The roasting process includes the yellowing period, the color fixing period and the gluten-drying period.

[0039] Yellowing period:

[0040] (1) Fire temperature control: raise the temperature in the barn to 35.5°C at a rate of 1°C / 3h, control the wet bulb temperature to 35.0°C, and stabilize the temperature for 2h; the frequency of the motor is changed to 30Hz, and the speed is 500r / min.

[0041] (2) Initial stage of yellowing: Raise the temperature in the barn to 37.0°C at a rate of 0.1°C / h, control the wet bulb temperature to 35.5°C, and stabilize the temperature for 30 hours; the frequency of the motor changes to 35Hz, and the speed is 720r / min.

[0042] (3) Middle stage of yellowing: Raise the temperature in the barn to 38.0°C at a rate of 0.1°C / h, control the wet bulb temperature to 36.5°C, and keep...

Embodiment 2

[0053] A method for curing tobacco leaves of flue-cured tobacco variety Yunyan 87. Yunyan 87 is planted in purple soil, and the lower tobacco leaves of Yunyan 87 are 55 days old during curing. The roasting process includes the yellowing period, the color fixing period and the gluten-drying period.

[0054] Yellowing period:

[0055] (1) Fire temperature control: Raise the temperature in the barn to 35.3°C at a rate of 1°C / 3h, control the wet bulb temperature to 35.2°C, and stabilize the temperature for 2h; the frequency of the motor changes to 32Hz, and the speed is 480r / min.

[0056] (2) Initial stage of yellowing: Raise the temperature in the barn to 36.8°C at a rate of 0.1°C / h, control the wet bulb temperature to 35.7°C, and stabilize the temperature for 34 hours; the frequency of the motor changes to 37Hz, and the speed is 700r / min.

[0057] (3) Middle stage of yellowing: Raise the temperature in the barn to 37.9°C at a rate of 0.1°C / h, control the wet bulb temperature to...

Embodiment 3

[0068] A method for curing tobacco leaves of flue-cured tobacco variety Yunyan 87. Yunyan 87 is grown in purple soil, and the upper leaf of Yunyan 87 is 115 days old during curing. The roasting process includes the yellowing period, the color fixing period and the gluten-drying period.

[0069] Yellowing period:

[0070] (1) Fire temperature control: Raise the temperature in the barn to 35.7°C at a rate of 1°C / 3h, control the wet bulb temperature to 35.2°C, and stabilize the temperature for 2h; the frequency of the motor changes to 28Hz, and the speed is 520r / min.

[0071] (2) Initial stage of yellowing: Raise the temperature in the barn to 36.8°C at a rate of 0.1°C / h, control the wet bulb temperature to 35.7°C, and keep the temperature stable for 28 hours; the frequency of the motor changes to 33Hz, and the speed is 740r / min.

[0072] (3) Middle stage of yellowing: Raise the temperature in the barn to 37.9°C at a rate of 0.1°C / h, control the wet bulb temperature to 36.7°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com