Three-dimension carbon cloth/nickel iron layer shaped hydroxide nanosheet composite material and application thereof

A layered hydroxide and composite material technology, applied in nickel compounds, analytical materials, material analysis by electromagnetic means, etc., can solve the problems of cumbersome preparation process, hindering electrode surface charge transfer efficiency, etc., and achieves simple preparation method, The effect of high charge transfer efficiency and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

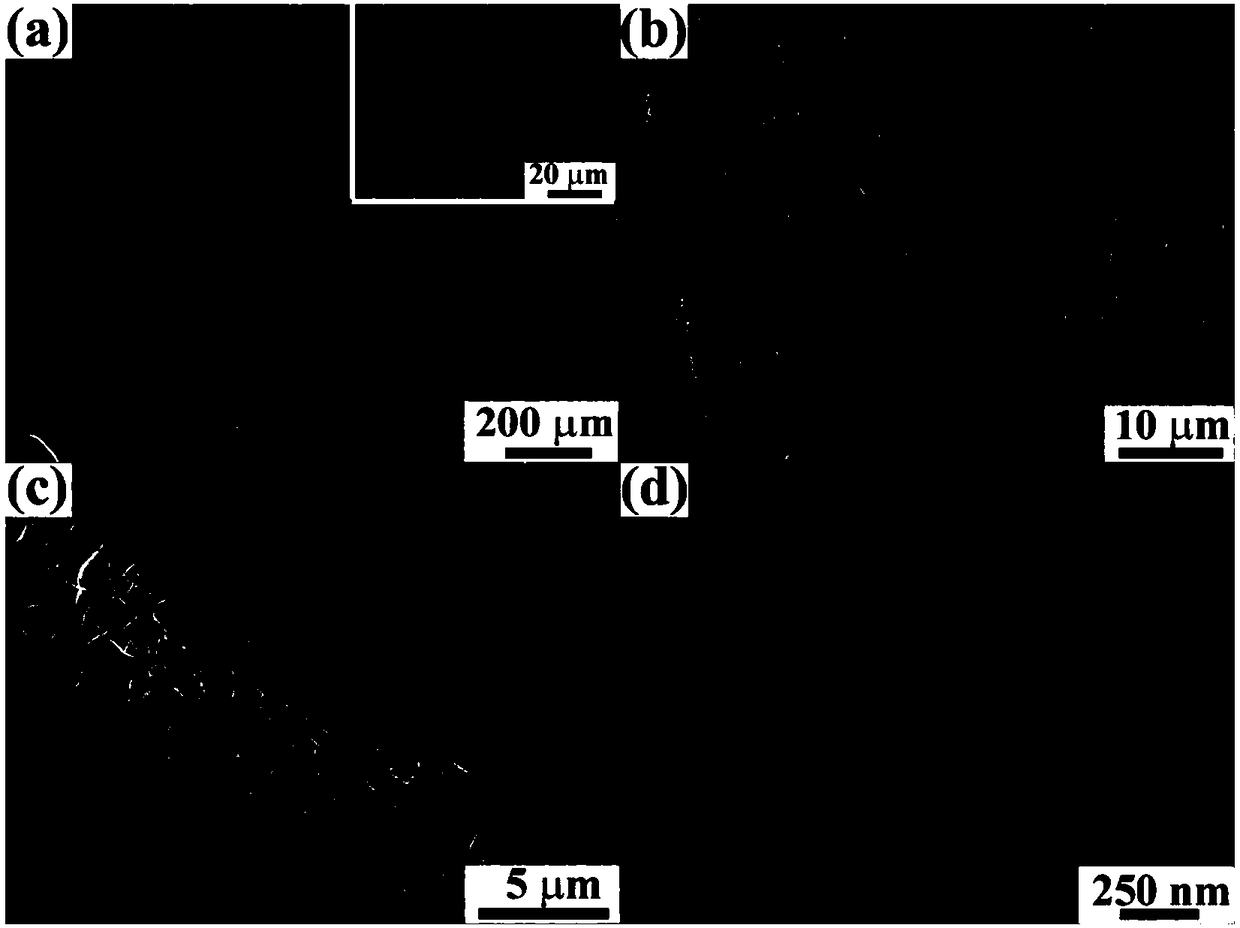

[0021] A three-dimensional carbon cloth / nickel-iron layered hydroxide nanosheet composite material, the preparation method of which comprises the following steps:

[0022] Step A, placing carbon in nitric acid with a concentration of 3 mol / L, and reacting for 2 hours at a reaction temperature of 100-120° C., so as to prepare a functionalized three-dimensional carbon cloth.

[0023] Step B, soaking the functionalized three-dimensional carbon cloth in ferric nitrate (ie Fe(NO 3 ) 3 ), nickel nitrate (i.e. Ni(NO ) 3 ) 2 ), urea (i.e. CO(NH 2 ) 2 ) and ammonium fluoride (ie NH 4 In the mixture of F), the molar ratio of ferric nitrate, nickel nitrate, urea and ammonium fluoride is 0.5:1.5:10:5, and the reaction temperature is 100-120 ℃ for 6-10 hours, and then cooled to room temperature, and washed and dried to prepare a three-dimensional carbon cloth / nickel-iron layered hydroxide nanosheet composite material.

[0024] Specifically, every 6cm 2 The amount of ferric nitrate ...

Embodiment 1

[0029] A three-dimensional carbon cloth / nickel-iron layered hydroxide nanosheet composite material, the preparation method of which comprises the following steps:

[0030] Step a. Arranging carbon with a size of 2cm×3cm in a high-pressure reactor filled with 3mol / L nitric acid, and reacting at a reaction temperature of 120°C for 2 hours to prepare a functionalized three-dimensional carbon cloth.

[0031]Step b. Dissolve 0.5mmol ferric nitrate, 1.5mmol nickel nitrate, 10mmol urea, and 5mmol ammonium fluoride in the same 35ml deionized water, mix them together, and then soak the functionalized three-dimensional carbon cloth in the mixture , continue stirring for 10 minutes, then transfer the mixture to a 50ml autoclave, and react at 120°C for 8 hours. After the reaction is completed, cool to room temperature, take out the obtained product and wash it thoroughly to remove the surface of the product. Physical attachment, and then place the product at 60°C for drying treatment, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com