Preparation method of high-calcium aluminum residue balls

A technology of aluminum slag balls and high calcium, which is applied in the field of molten steel refining and slag adjustment, can solve the problems of large air pollution and high cost of pure aluminum, and achieve the effects of good surface stability, high raw material utilization rate, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

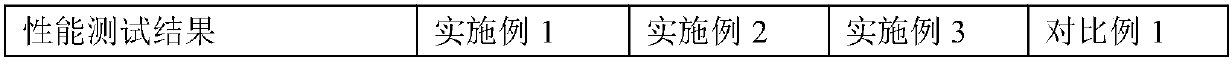

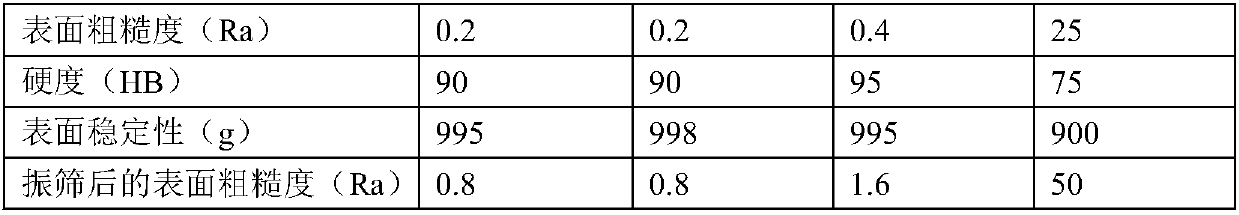

Examples

Embodiment 1

[0037] A preparation method of high-calcium aluminum slag balls, comprising the following steps:

[0038] S1: Take 100kg of bauxite and pour it into the first reaction tank, add hydrochloric acid to the first reaction tank to submerge the bauxite, and soak for 4 hours, the Al in the bauxite 2 o 3 The content is 70wt%, and the concentration of hydrochloric acid is 5mol / L;

[0039] S2: Filter the solution in the first reaction tank and transfer it to the second reaction tank, and pass ammonia gas into the solution in the second reaction tank until the pH of the solution reaches 7;

[0040] S3: Pump out the solution in the second reaction tank and dry it in a reaction kettle with a pressure of 4kPa and a temperature of 30°C for 2 hours to obtain NH 4 Cl crystallization;

[0041] S4: Take out the solid in the second reaction tank and put it into a stirring pot, add 100kg of limestone, stir evenly, move it to a high-temperature reaction furnace, and calcinate at a temperature of...

Embodiment 2

[0046] A preparation method of high-calcium aluminum slag balls, comprising the following steps:

[0047] S1: Take 110kg of bauxite and pour it into the first reaction tank, add hydrochloric acid to the first reaction tank to submerge the bauxite, and soak for 4 hours, the Al in the bauxite 2 o 3 The content is 68wt%, and the concentration of hydrochloric acid is 5.3mol / L;

[0048] S2: filter the solution in the first reaction tank and transfer it to the second reaction tank, and pass ammonia gas into the solution in the second reaction tank until the pH of the solution reaches 7.5;

[0049] S3: Pump out the solution in the second reaction tank and dry it in a reaction kettle with an air pressure of 3.5kPa and a temperature of 28°C for 2.5 hours to obtain NH 4 Cl crystallization;

[0050] S4: Take out the solid in the second reaction tank and put it into the stirring pot, add 105kg of limestone, stir evenly, move it to a high-temperature reaction furnace, and calcinate at 9...

Embodiment 3

[0055] A preparation method of high-calcium aluminum slag balls, comprising the following steps:

[0056] S1: Take 98kg of bauxite and pour it into the first reaction tank, add hydrochloric acid to the first reaction tank to submerge the bauxite, and soak for 4 hours, the Al in the bauxite 2 o 3 The content is 72wt%, and the concentration of hydrochloric acid is 4.8mol / L;

[0057] S2: Filter the solution in the first reaction tank and transfer it to the second reaction tank, and pass ammonia gas into the solution in the second reaction tank until the pH of the solution reaches 7;

[0058] S3: Pump out the solution in the second reaction tank and dry it for 3 hours in a reaction kettle with an air pressure of 4.5kPa and a temperature of 35°C to obtain NH 4 Cl crystallization;

[0059] S4: Take out the solid in the second reaction tank and put it into a stirring pot, add 95kg of limestone, stir evenly, move it to a high-temperature reaction furnace, and calcinate at a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com