A kind of expandable graphite flame retardant with surface coated nanoparticles and preparation method thereof

A technology of expanded graphite and nano particles, which is applied in the field of expandable graphite halogen-free flame retardants, can solve the problems of poor compatibility between expandable graphite and polyurethane matrix, and the expansion ratio of expandable graphite has not been improved, so as to achieve optimal compatibility, Increased expansion ratio and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Another specific embodiment of the present invention discloses a preparation method of an expandable graphite flame retardant coated with nanoparticles on the surface. When performing a coating, the specific process steps are as follows:

[0058] Step 1. Add the metal salt and expandable graphite into the three-necked flask at the same time, add enough water or distilled water to dissolve the metal salt, and completely dissolve the metal salt by stirring at 200rad / min to 800rad / min;

[0059] Step 2. Use alkaline solution to adjust the pH of the solution. When the set pH value is reached, start to heat up to 50°C-90°C, and ripen in the temperature range of 40°C-95°C for 1h-24h, and the stirring rate during ripening is 100rad / min-500rad / min, and finally air-cooled to room temperature;

[0060] Step 3. Washing with an appropriate amount of water or distilled water, filtering, and drying to obtain an expandable graphite flame retardant coated with a metal hydroxide nanopar...

Embodiment 1

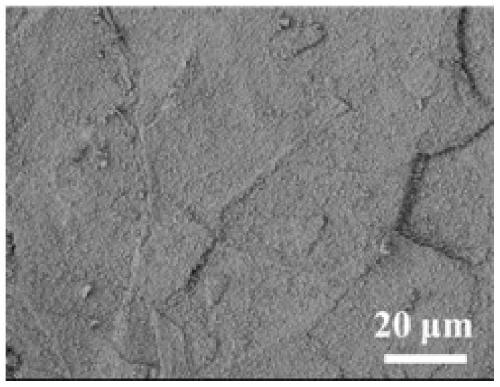

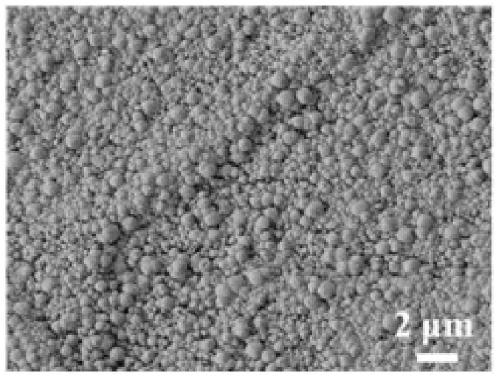

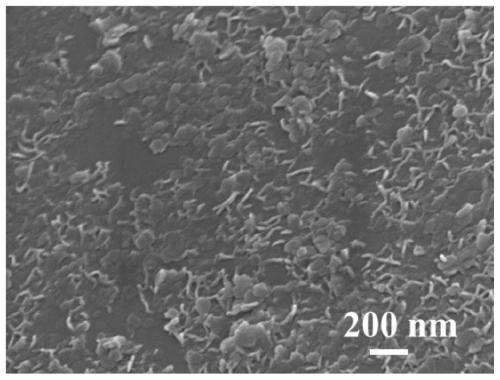

[0081] Add 88.5g of aluminum sulfate octadecahydrate, 25g of 50-mesh EG and 500ml of deionized water into a 1000ml three-necked flask, adjust the pH to 4 with sodium hydroxide solution, raise the temperature to 80°C, reflux for 6 hours, and cool down to room temperature , washed with sufficient deionized water, filtered, and dried to obtain gray powder EG@ATH, whose SEM is as follows Picture 1-1 , 1-2 shown. The expansion ratio results are shown in Table 1. Expansion rate from 163ml g -1 Increased to 197ml g-1 .

Embodiment 2

[0083] Add 88.5g of aluminum sulfate octadecahydrate, 11.16g of 50-mesh EG and 500ml of deionized water into a 1000ml three-neck flask, adjust the pH to 4.5 with sodium hydroxide, heat up to 90°C, reflux for 8 hours, and cool down to room temperature , washed with sufficient deionized water, filtered, and dried to obtain gray powder EG@ATH. The expansion ratio results are shown in Table 1. Expansion rate from 163mlg -1 Increased to 197ml g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com