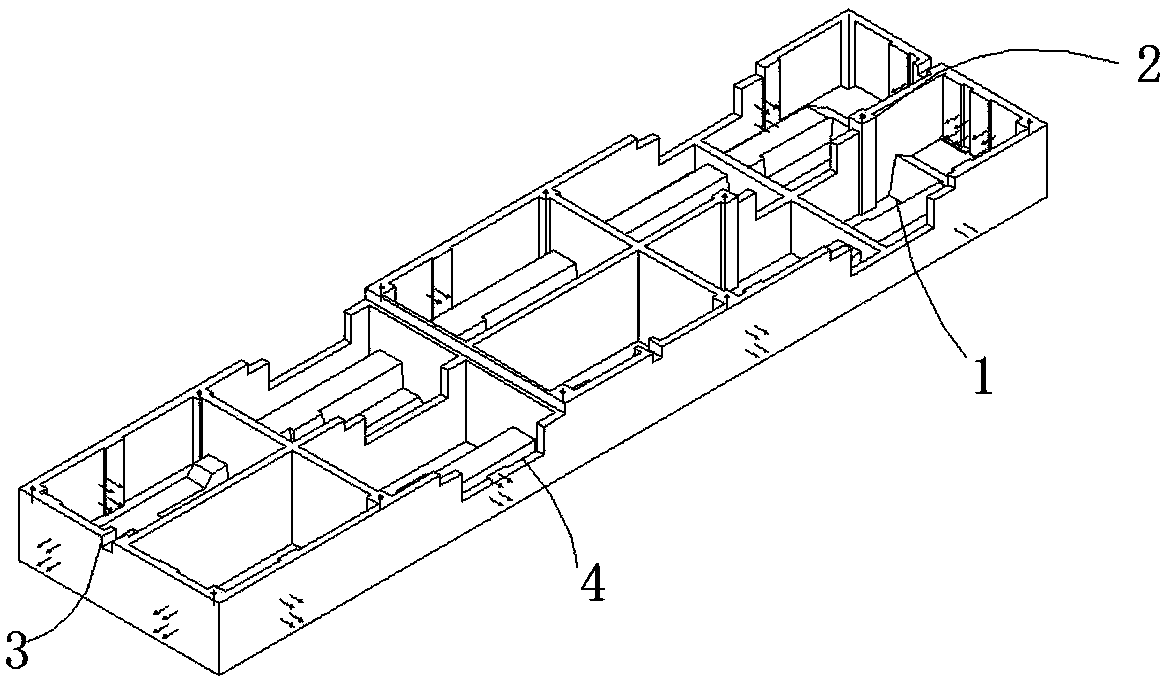

Quick casting process for door-type plates in household appliance industries

A rapid casting and home appliance technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as low operating efficiency, difficulty in guaranteeing casting quality, and inability to cover molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

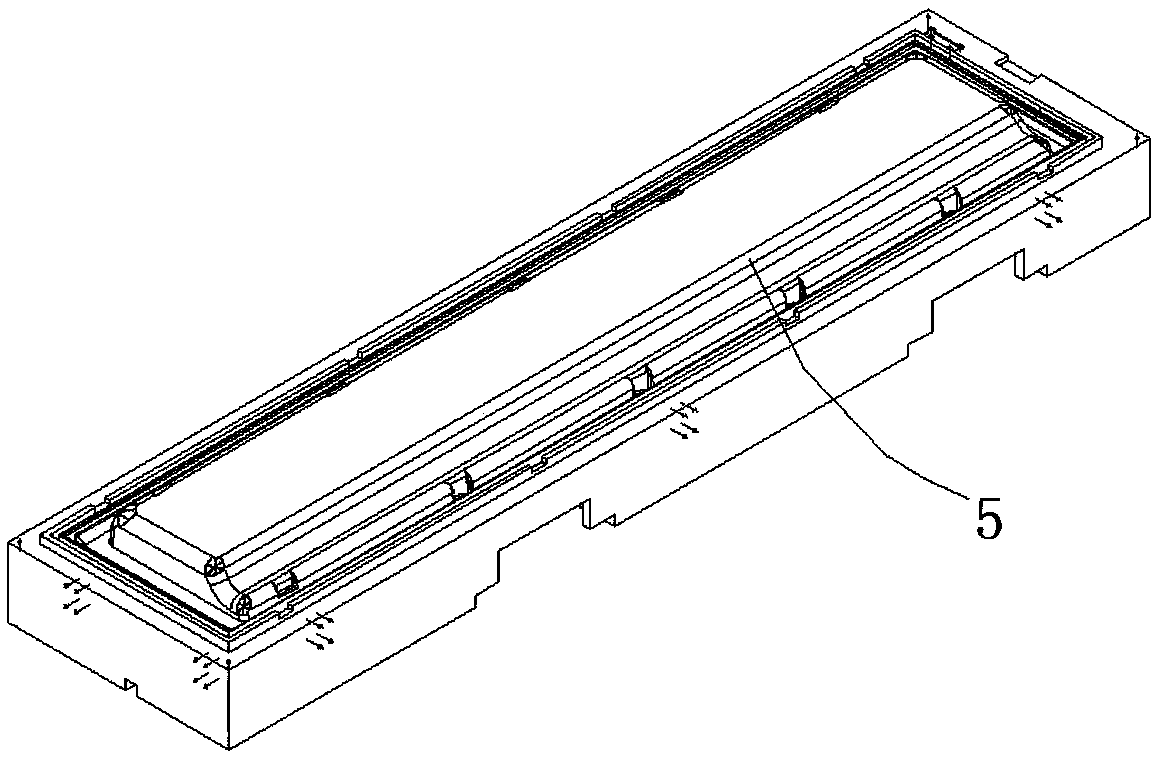

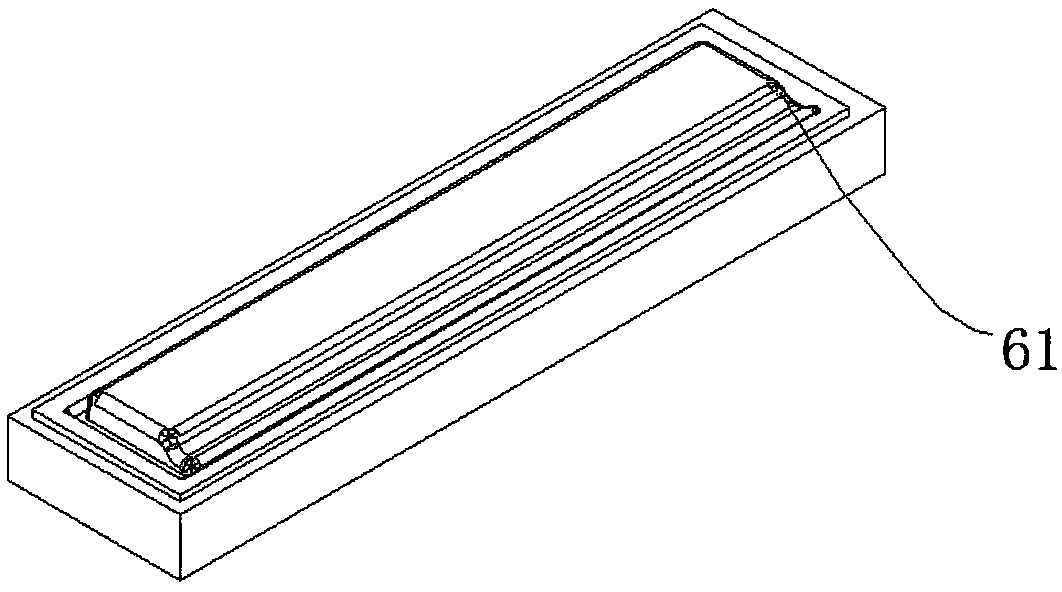

[0061] 1) Use the three-dimensional software to perform parting operation on the upper box, select the parting surface as the bottom surface, and the separated models are the rib model of foam material, the upper box upper mold model 62 adapted to the chamber, and the convex The upper box lower mold model 61 adapted from 5, wherein the upper box upper mold model 62 is an inner shape, in order to facilitate operation in the modeling, so the upper box upper mold model 62 and the upper box body should be taken as the zero point of the parting surface Make a convex shape, so that the above models are all convex;

[0062] 2) Send the output of the upper box body lower mold model 61, the upper box body upper mold model 62 and the rib model to the model processing workshop for processing, and the obtained casting model is to be cast;

[0063] 3) Place the upper mold model 62 of the upper box on the vacuum molding table panel 63 of the upper box, and control the negative pressure at 0...

Embodiment 2

[0069] 1) Use the three-dimensional software to carry out the parting operation of the lower box, select the parting surface as the bottom surface, and the separated models are the lower box lower mold model 81 and the lower box upper mold model 82, wherein the lower box upper mold The model 82 is an inner shape. In order to facilitate operation in the molding, the upper mold model 82 of the lower box body is made into a convex shape with the parting surface as the zero point, so that the above-mentioned models are all convex;

[0070] 2) Send the output of the lower box lower mold model 81 and the lower box upper mold model 82 to the model processing workshop for processing, and the obtained casting model is to be cast;

[0071] 3) Place the lower box lower mold model 81 on the lower box vacuum molding table panel 83, and control the negative pressure at 0.05Mpa. After baking and covering, put the No. 1 sandbox 84 of the lower box on the lower box On the lower mold model 81, ...

Embodiment 3

[0077] The V method casting coating includes the following components by weight: 100kg of composite refractory powder, 4kg of organic binder, 4kg of suspending agent, 1kg of auxiliary agent, and 40kg of solvent, wherein the particle size of the composite refractory powder is 5um. Prepared in the following steps:

[0078] S1. Prepare composite refractory powder, put zircon powder, graphite, bauxite, and iron red into a ball mill for ball milling, make it evenly mixed, and obtain a particle size of 3-7um;

[0079] S2. Mix the prepared refractory powder with other remaining ingredients, put them into a high-speed mixer, stir and disperse at a speed of 16000 rpm for 3 hours to obtain a mixture;

[0080] S3, put the mixed material into a ball mill for ball milling, so that the particle size of the obtained slurry is below 15 μm, and adjust the viscosity as required, to obtain final product;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com