Traditional Chinese medicine crusher having auxiliary grinding function

A technology of traditional Chinese medicine pulverizer and pulverizer, which is applied in the direction of grain processing, etc., and can solve the problems of filtration treatment and inability to pulverize all medicinal materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

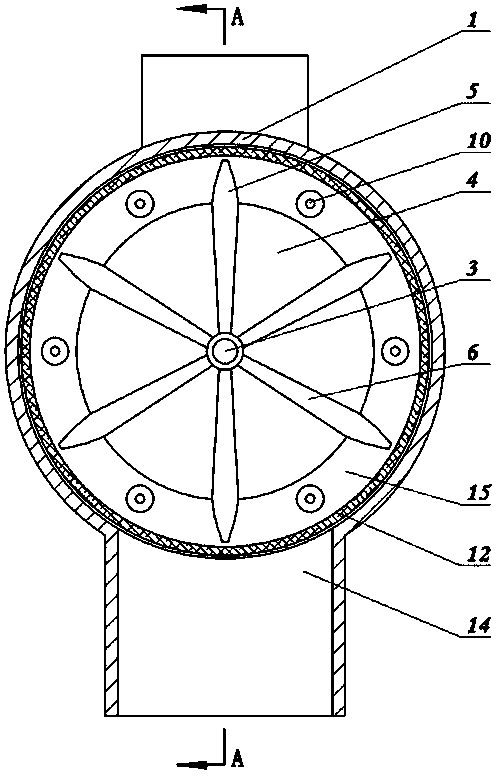

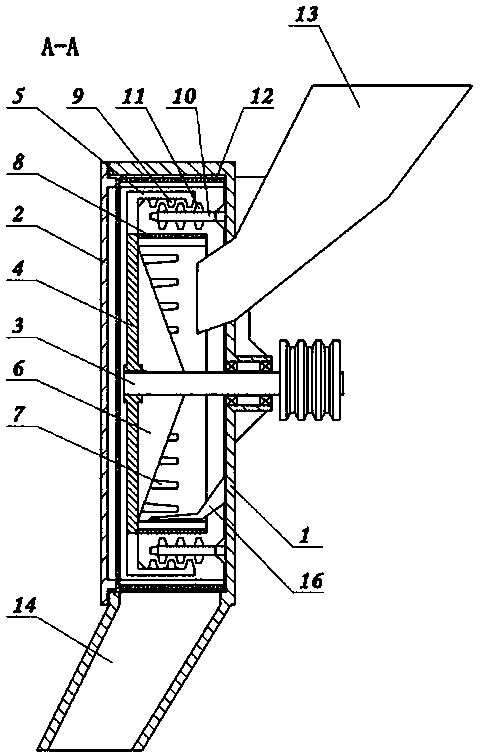

[0016] Embodiment 1: as figure 1 The shown traditional Chinese medicine grinder has dual functions of crushing and auxiliary grinding. The pulverizer includes a pulverizer shell 1, a rotating shaft 3, a driving mechanism, and structures such as a feed hopper 13 and a discharge hopper 14 communicated with the pulverizer chamber.

[0017] A turntable 4 is fixed on the rotating shaft 3, and radial ribs 6 are evenly distributed on the turntable 4. On the basis of each radial rib 6, outwardly protruding crushing teeth 7 are arranged in the axial direction. On the turntable 4 The periphery of the ring is provided with an annular inner layer filter screen 8. Among them, the radial ribs 6 on the turntable 4 are thicker near the rotating shaft 3 than the surrounding area, forming a triangular structure, and each crushing tooth 7 is respectively located on the hypotenuse of the corresponding radial ribs 6 .

[0018] Utilize the outer filter 12 to wrap the inside of the turntable 4 to ...

Embodiment 2

[0021] Embodiment 2: On the basis of Embodiment 1, an outer layer filter screen 12 is matched in the crushing chamber, the feeding hopper is connected to the middle part of the outer layer filter screen 12, and the outlet hopper is located at the outer layer filter screen. 12 below.

Embodiment 3

[0022] Embodiment 3: The crushing teeth 7 include blunt-face teeth and face-face teeth, which are distributed alternately. Utilizing the cutting function of the facet teeth, large pieces of branches and leaves can be shortened and shredded to prevent the problem that large pieces of flexible or damp materials cannot fall off and cannot be crushed when attached to the turntable 4 and the crushing teeth 7 . The blunt teeth can be used to quickly impact harder medicines to crush them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com