Anti-explosion anti-shock steel deck pavement structure and pavement method

A steel bridge deck, anti-shock technology, used in bridges, bridge parts, bridge construction and other directions, can solve the problems of the anti-explosion design method to be optimized, the anti-explosion design method lacks consideration of anti-explosion performance, etc., and achieves good low temperature crack resistance. The effect of deformation ability with followers, good interlayer bonding, and enhanced applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

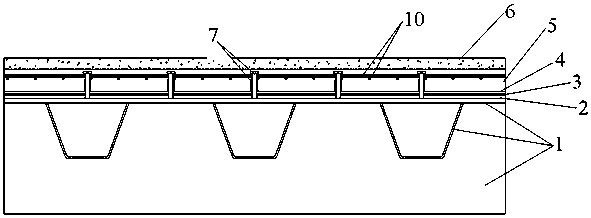

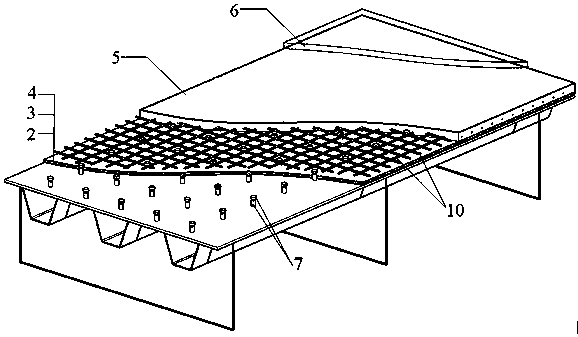

[0042] Such as figure 1 , figure 2 As shown, an explosion-proof and impact-proof steel bridge deck pavement structure, including orthotropic steel bridge deck 1, Eliminator waterproof bonding layer 2, Kevlar laminated sheet 3, bonding layer 4. Steel fiber concrete explosion-proof layer 5 and asphalt concrete wear layer 6;

[0043] The Eliminator waterproof adhesive layer 2 is laid on the orthotropic steel bridge deck 1, and the Eliminator waterproof adhesive layer 2 and the Kevlar laminated sheet 3 are bonded with epoxy resin;

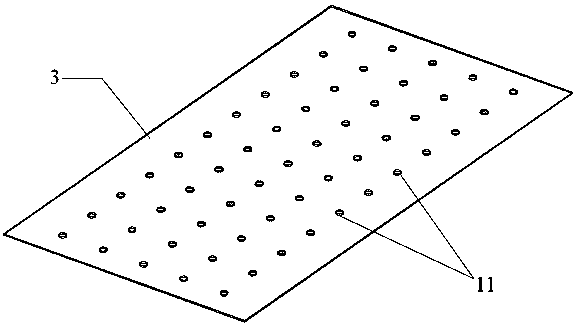

[0044] The upper surface of the orthotropic steel bridge deck 1 is provided with a welding stud-rubber flexible combined connector 7, and the Kevlar laminated sheet 3 is provided with holes corresponding to the position of the welded stud-rubber flexible combined connector 7 11; the top surface of the welding stud-rubber flexible combined connector 7 is 5mm lower than the surface of the steel fiber concrete explosion-proof layer 5; the inside of the...

Embodiment 2

[0063] An explosion-proof and impact-proof steel bridge deck pavement structure, comprising orthotropic steel bridge deck 1, Eliminator waterproof bonding layer 2, Kevlar laminated sheet 3, bonding layer 4, steel Fiber concrete explosion-proof layer 5 and asphalt concrete wear layer 6;

[0064] The Eliminator waterproof adhesive layer 2 is laid on the orthotropic steel bridge deck 1, and the Eliminator waterproof adhesive layer 2 and the Kevlar laminated sheet 3 are bonded with epoxy resin;

[0065] The upper surface of the orthotropic steel bridge deck 1 is provided with a welding stud-rubber flexible combined connector 7, and the Kevlar laminated sheet 3 is provided with holes corresponding to the position of the welded stud-rubber flexible combined connector 7 11; the top surface of the welding stud-rubber flexible combined connector 7 is 10mm lower than the surface of the steel fiber concrete explosion-proof layer 5; the inside of the steel fiber concrete explosion-proof l...

Embodiment 3

[0084] An explosion-proof and impact-proof steel bridge deck pavement structure, comprising orthotropic steel bridge deck 1, Eliminator waterproof bonding layer 2, Kevlar laminated sheet 3, bonding layer 4, steel Fiber concrete explosion-proof layer 5 and asphalt concrete wear layer 6;

[0085] The Eliminator waterproof adhesive layer 2 is laid on the orthotropic steel bridge deck 1, and the Eliminator waterproof adhesive layer 2 and the Kevlar laminated sheet 3 are bonded with epoxy resin;

[0086] The upper surface of the orthotropic steel bridge deck 1 is provided with a welding stud-rubber flexible combined connector 7, and the Kevlar laminated sheet 3 is provided with holes corresponding to the position of the welded stud-rubber flexible combined connector 7 11; the top surface of the welding stud-rubber flexible combined connector 7 is lower than the surface of the steel fiber concrete explosion-proof layer 5 by 8mm; the inside of the steel fiber concrete explosion-proof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com