Composite material structural part with metal flange and preparation method thereof

A technology of composite materials and structural parts, used in flange connection, passing components, mechanical equipment, etc., can solve the problem of difficult to guarantee sealing performance, and achieve the effect of improving sealing performance, reducing weight, and ensuring accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

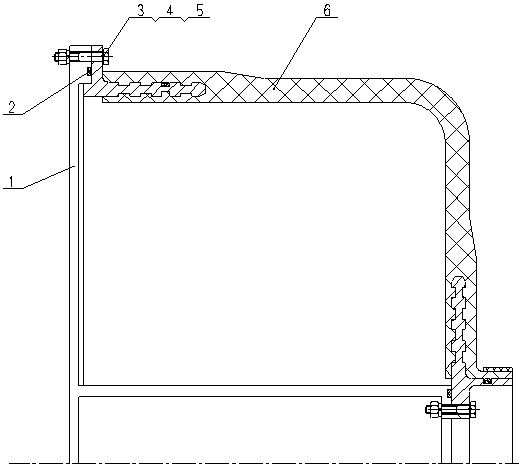

[0034] refer to figure 1 As shown, the composite structural member 6 and the external structural member 1 are fixedly connected together by bolts 3, elastic gaskets 4 and nuts 5, and the O-ring 2 is made of fluororubber to play a sealing role.

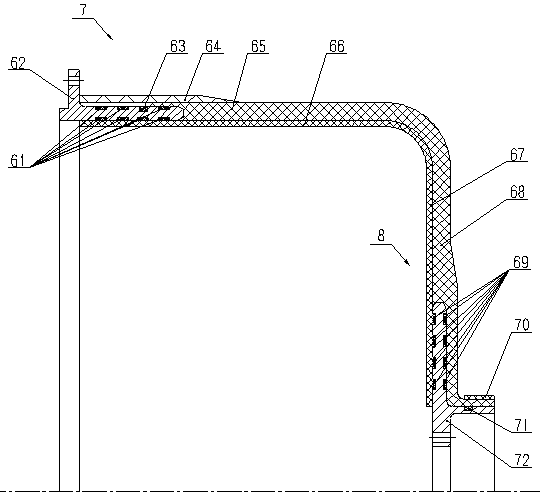

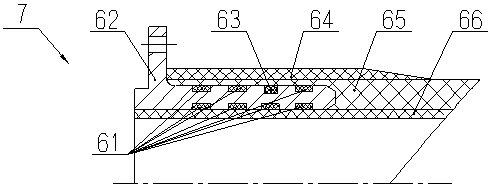

[0035] refer to figure 2 As shown, the composite material structure 6 of the present invention is composed of metal flanges at both ends, a composite material body and an O-shaped sealing ring 2, and the composite material body is selected from a material that matches the sealing liquid and the service temperature. Type sealing ring 2 is pre-embedded in the sealing groove of the metal flange, and the material matching the composite material resin and curing temperature is selected. The connection method of the sealing ring connects the composite material structural part and the external structural part 1 together to achieve the functions of sealing and bearing.

[0036]Among them, the metal flange has two structural forms:

[0037]...

Embodiment 2

[0043] Example 2 is a further example.

[0044] The difference from Embodiment 1 is that the circular metal flange 62 and the end plate metal flange 72 are made of ordinary carbon steel Q235B.

Embodiment 3

[0045] Embodiment 3 is yet a further embodiment.

[0046] The difference from Embodiment 1 is that the annular metal flange 62 and the end plate metal flange 7272 are made of high-strength aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com