System for preparing super-hydrophilic non-woven fabric

A non-woven fabric and super-hydrophilic technology, applied in the field of super-hydrophilic non-woven fabric preparation system, can solve the problems of waste of hydrophilic agent raw materials, low production efficiency, cumbersome operation, etc., and achieve enhanced hydrophilic performance and uniform thickness , the effect of meeting the requirements of hydrophilic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

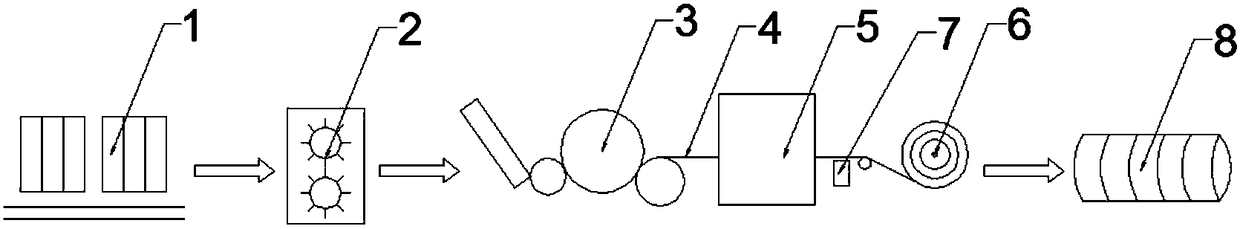

[0032] like figure 1 As shown, a system for preparing superhydrophilic nonwoven fabrics includes a cotton feeder 1, an opener 2, a carding machine 3, a mesh belt 4, a hot blast stove 5, a winding device 6 and a cutting machine connected in sequence. Device 8 is provided with a corona device 7 for increasing hydrophilic groups on the surface of the nonwoven fiber between the hot blast stove 5 and the winding device 6, and the corona device 7 is arranged below the nonwoven mesh surface, and the width is the same as The effective width of mesh belt 4 is the same.

[0033] Using PP / PE 2D two-component skin-core structural fibers as raw materials to prepare super-hydrophilic nonwovens includes the following steps:

[0034] S1, opening: the fiber is opened by the opening machine 2;

[0035] S2, carding: after the fibers after opening are carded by the carding machine 3, the mesh is laid on the mesh belt 4;

[0036] S3, hot air setting: thermally bonding the fiber web after laying...

Embodiment 2

[0042] Using PET / PE 1.5D two-component skin-core structural fibers as raw materials to prepare super-hydrophilic nonwovens, including the following steps:

[0043] S1, opening: the fiber is opened by the opening machine 2;

[0044] S2, carding: after the fibers after opening are carded by the carding machine 3, the mesh is laid on the mesh belt 4;

[0045] S3, hot air setting: thermally bonding the fiber web after laying through the hot air furnace 5, so that the nonwoven fabric is shaped;

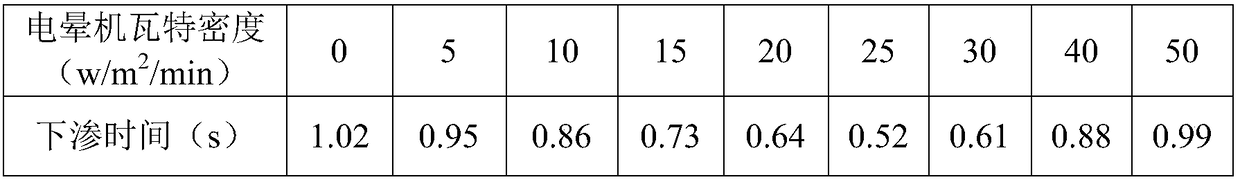

[0046] S4, corona treatment: Corona treatment is carried out on the nonwoven fabric after shaping through the corona device 7, so that the surface of the fiber generates hydrophilic groups, and the watt density parameter of the corona device 7 is set to 20w / m 2 / min;

[0047] S5, winding: the nonwoven fabric treated by the corona device 7 is wound into a roll by the winding device 6;

[0048]S6. Slitting and packaging: the roll-shaped nonwoven fabric is slit and packaged by the slitting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com