Glass Gradient Bevel Grinding Method

A grinding and glass technology, applied in grinding/polishing equipment, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problems of low product added value, inability to grind variable width bevels, and single product form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

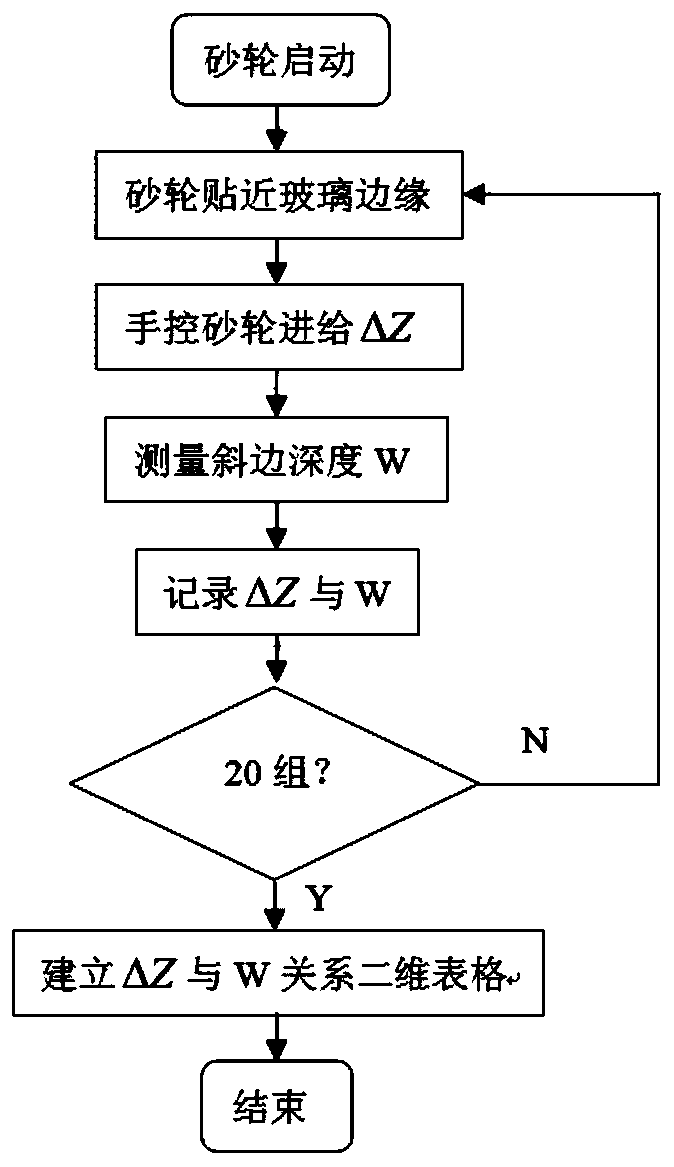

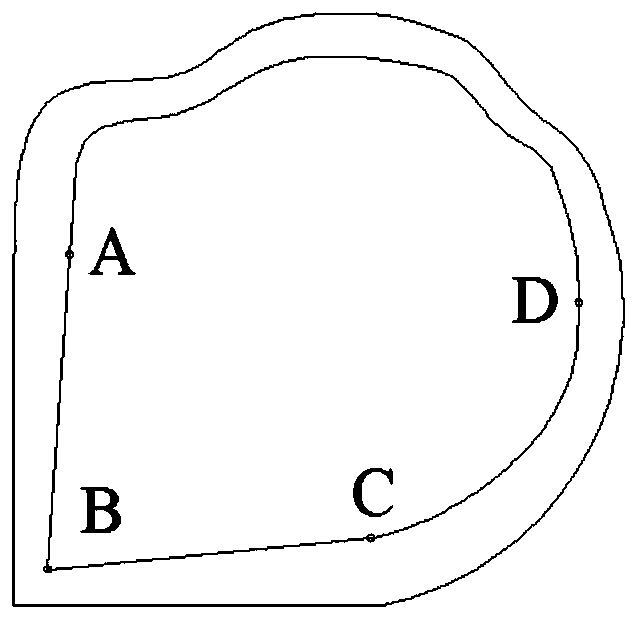

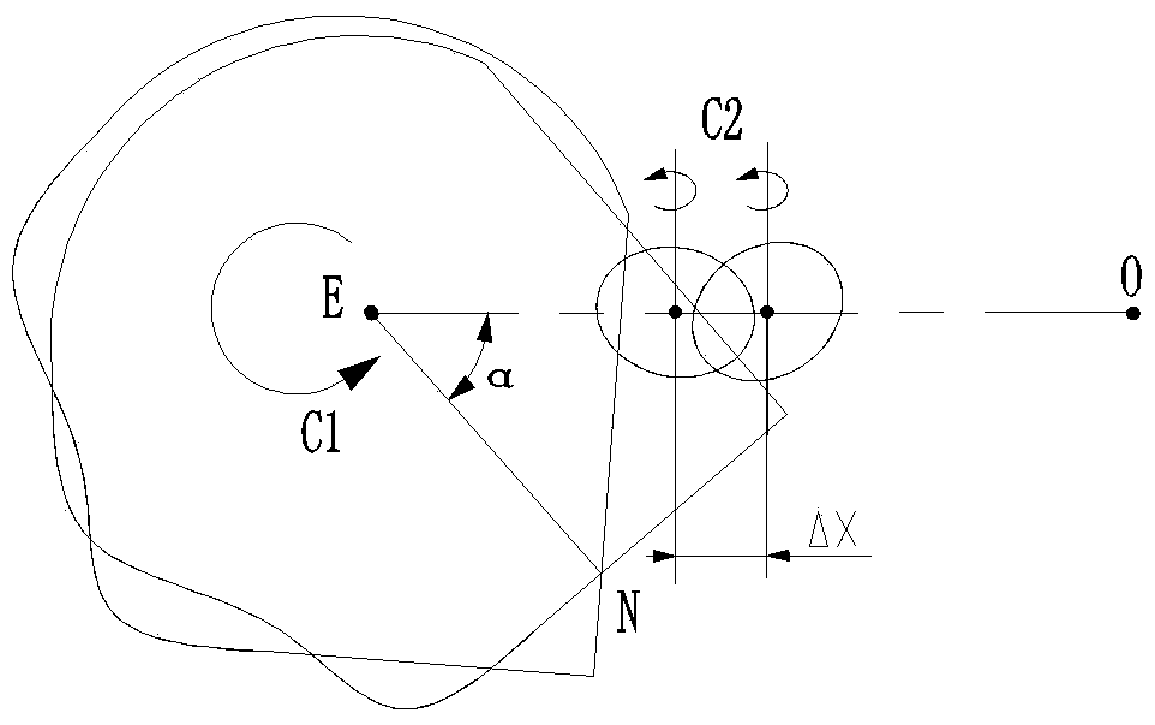

[0081] In the glass gradient bevel grinding method, the realization of the method is based on a four-axis linkage glass edge grinding equipment, wherein the four axes are: C1 axis, X axis, Z axis and C2 axis; specifically, C1 axis It can realize the rotating movement of the glass during the grinding process; the X axis can realize the forward and backward movement of the grinding wheel during the grinding process; the Z axis can realize the up and down movement of the grinding wheel during the grinding process; the C2 axis can realize the rotating movement of the grinding wheel around the Z axis, and The grinding direction is always tangential to the direction of the glass contour.

[0082] Among them, the four-axis linkage glass edging equipment includes a feeding device, which includes three CNC axes of X, Y and C. The three CNC axes of X, Y and C can realize the three-point positioning function of the glass and the automatic conveying of the glass between different stations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com