Liquid mulch film containing micro nano micro silica fume suspension matter and preparation method of mulch film

A technology of liquid mulch and micro-silica fume, applied in botany equipment and methods, liquid fertilizer, plant protection, etc., can solve the problems of poor film formation, reduce production costs, improve natural disaster resistance, and simplify the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

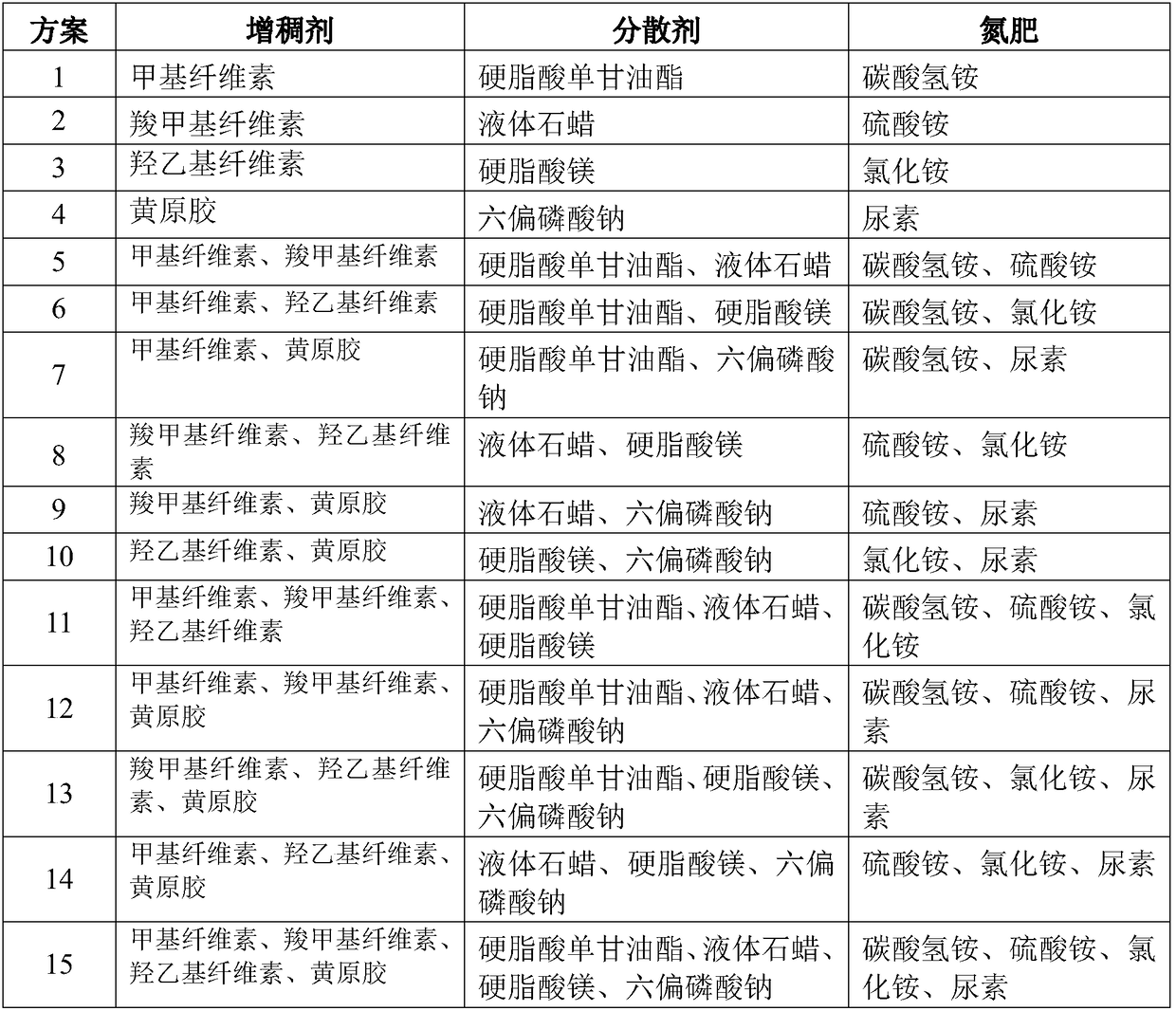

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the liquid mulch containing micro-nano micro-silica powder suspension in this embodiment is:

[0034] Calculate according to the total weight of 100g, (1) take 20g and the density is 1.83g / m 3 10g of stearic acid monoglyceride as a dispersant and 35g of water, mix well and ultrasonically for 16min under mechanical stirring conditions to obtain a stable and uniformly dispersed microsilica suspension aqueous solution; (2) Weigh 10g of methyl fiber As a thickener, 10g of ammonium bicarbonate as nitrogen fertilizer and 12g of water, mix well and let stand for 2h; (3) Add 3g of polyvinyl alcohol to the solution prepared in (1)(2) above, Under the condition of 95℃ water bath, the reaction is mechanically stirred for 60min; cooled to normal temperature, the sample is taken and tested after being qualified, and then the finished product is measured and packaged. The liquid mulch film obtained above is sprayed on the surface of the ground by spraying equip...

Embodiment 2

[0036] The preparation method of the liquid mulch containing micro-nano micro-silica powder suspension in this embodiment is:

[0037] Calculated according to the total weight of 100g, (1) Take 19g and the density is 1.60g / m 3 1g of liquid paraffin as a dispersant and 45g of water, mix well and ultrasonicate for 14 minutes under mechanical stirring conditions to obtain a stable and uniformly dispersed microsilica suspension aqueous solution; (2) Weigh 1g of carboxymethyl cellulose as a Thickener, 5.5g of ammonium bicarbonate as nitrogen fertilizer and 28g of water, mix well and let stand for 2h; (3) Add 0.5g of polyvinyl alcohol to the solution prepared in (1)(2) above, Under the condition of water bath at ℃, the reaction is mechanically stirred for 20 minutes; cooled to normal temperature, and the sample is taken after the inspection is qualified, and then measured and packaged, and then enters the finished product. The liquid mulch film obtained above is sprayed on the surface ...

Embodiment 3

[0039] The preparation method of the liquid mulch containing micro-nano micro-silica powder suspension in this embodiment is:

[0040] Calculated according to the total weight of 100g, (1) take 10g density as 1.42g / m 3 5g of magnesium stearate as a dispersant and 38.5g of water, mixed well and ultrasonicated for 10min under mechanical stirring conditions to obtain a stable and uniformly dispersed microsilica suspension aqueous solution; (2) Weigh 8g of hydroxyethyl fiber As a thickener, 6g of ammonium chloride as a nitrogen fertilizer and 30g of water, mix well and let stand for 2h; (3) Add 2.5g of polyvinyl alcohol to the solution prepared in (1) and (2) above, Under the conditions of a water bath at 80°C, the reaction is mechanically stirred for 40 minutes; cooled to room temperature, and the sample is taken to pass the inspection, and then the finished product is measured and packaged. The liquid mulch film obtained above is sprayed on the surface of the ground by spraying equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com