A new type of composite block

A block and silt technology, applied in the field of new composite sintered block production, can solve problems such as lack of mechanical properties, different types of mortise and dovetail grooves, lack of design methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

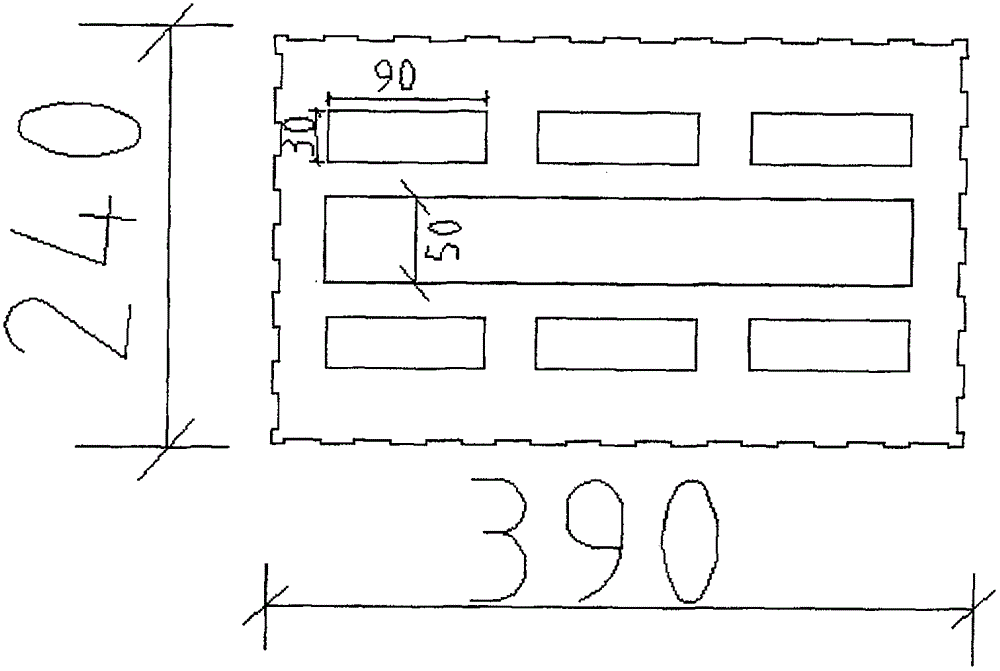

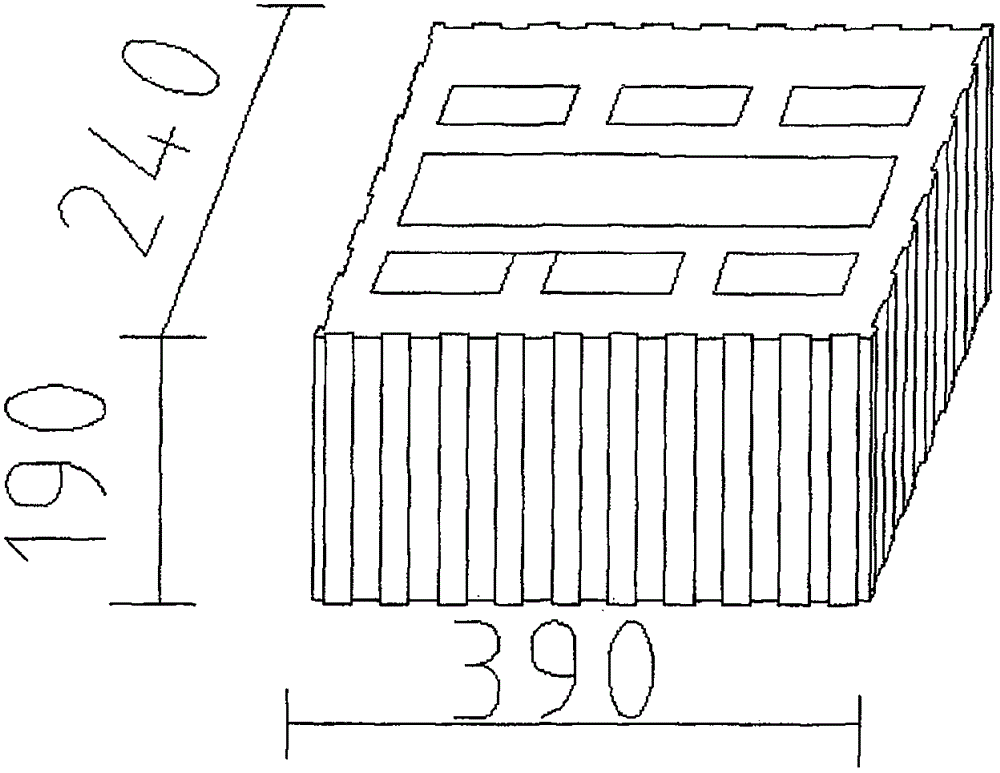

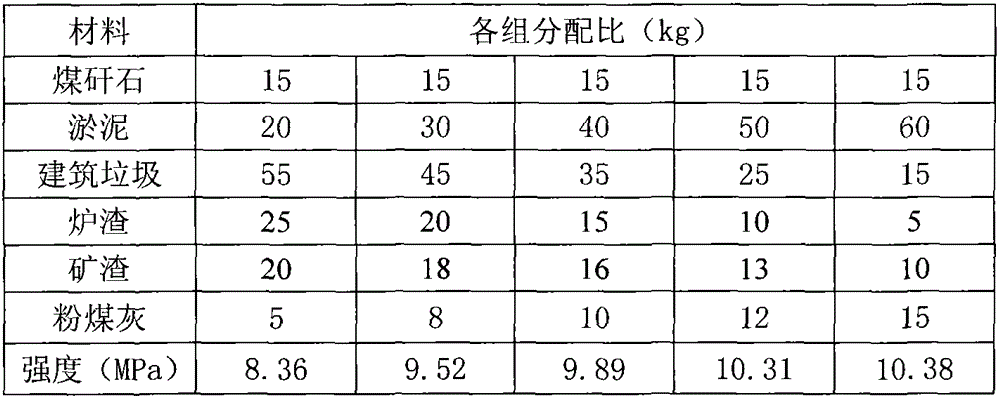

[0010] After the designed and measured coal gangue, fly ash, mud cake, construction waste powder, slag, slag, waste coal slag and reinforcing agent are uniformly stirred, they are aged for 48 hours and set aside. The aged material is made into adobe, and the dimensions of the wet adobe are: length 250mm, width 250mm, height 92mm. After drying (by using the heat released from the flue of the roasting kiln), the dimensions of the dry brick are: length 242mm, width 242mm, height 91mm, moisture content less than 7%. Send it to the wheel kiln for roasting, the empty box roasting temperature is 800℃~1100℃, and it can be made into solid waste sintered bricks. The finished bricks were tested for compressive strength, and the experimental results are shown in Tables 1-4.

[0011] Table 1 The weight ratio of each component in the trial mixing process of solid waste sintered bricks (admixture 0%)

[0012]

[0013] Table 2 The weight ratio of each component in the trial mixing proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com