Ordered membrane electrode based on metal oxide nanoribbon as well as preparation and application thereof

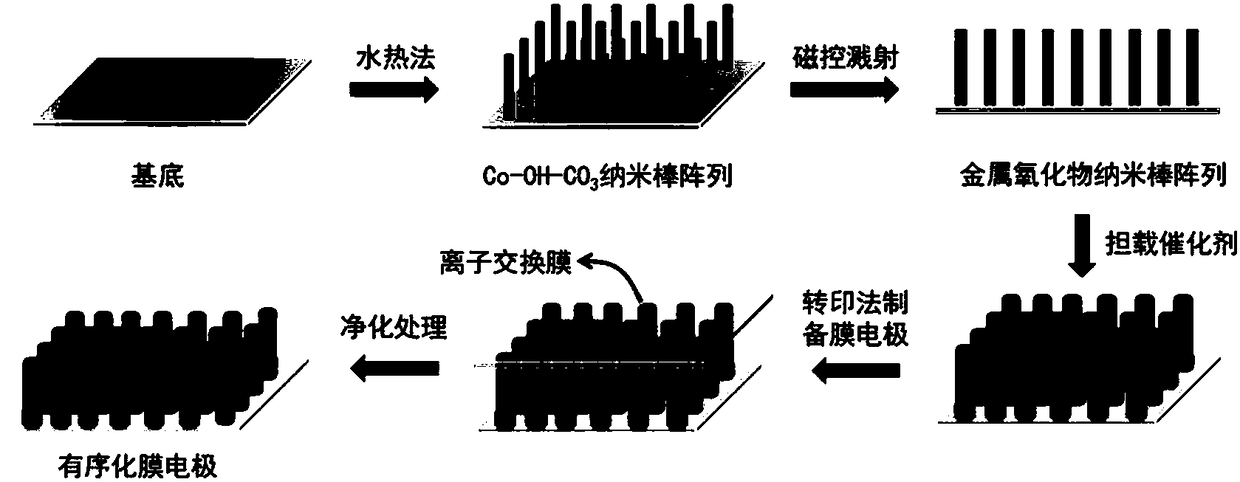

A technology of oxides and membrane electrodes, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problems of low catalyst utilization, large thickness of catalytic layer, high catalyst dosage, etc., and achieve the goal of catalyst group Adjustable temperature, mild preparation conditions, and thin catalytic layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

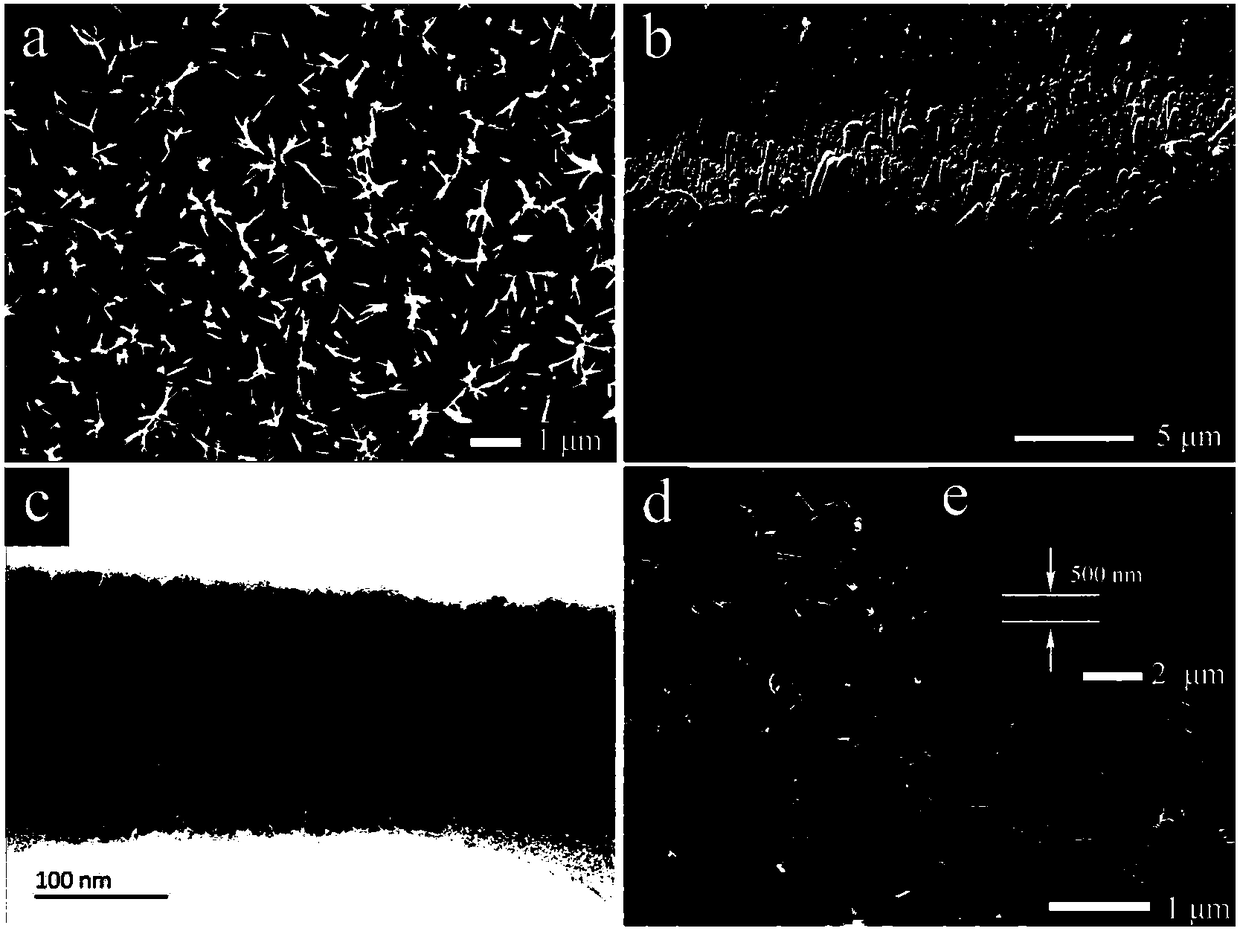

[0066] Preparation of Co-OH-CO by hydrothermal method using stainless steel as substrate 3 array. The reaction solution was 10 mM ammonium fluoride, 25 mM urea, and 5 mM cobalt nitrate. React in a high-pressure reactor at 120°C for 5 hours to prepare Co-OH-CO on the substrate 3 array. figure 2 a) shows the prepared Co-OH-CO 3 SEM image of the array. It can be seen from the figure that Co-OH-CO 3 The nanorod array grows uniformly on the substrate, and the growth direction is substantially perpendicular to the substrate. Co-OH-CO 3 The length of the nanorod is about 3μm, the diameter is about 100nm, Co-OH-CO 3 The areal density of nanorods is 3-4e 9 / cm 2 .

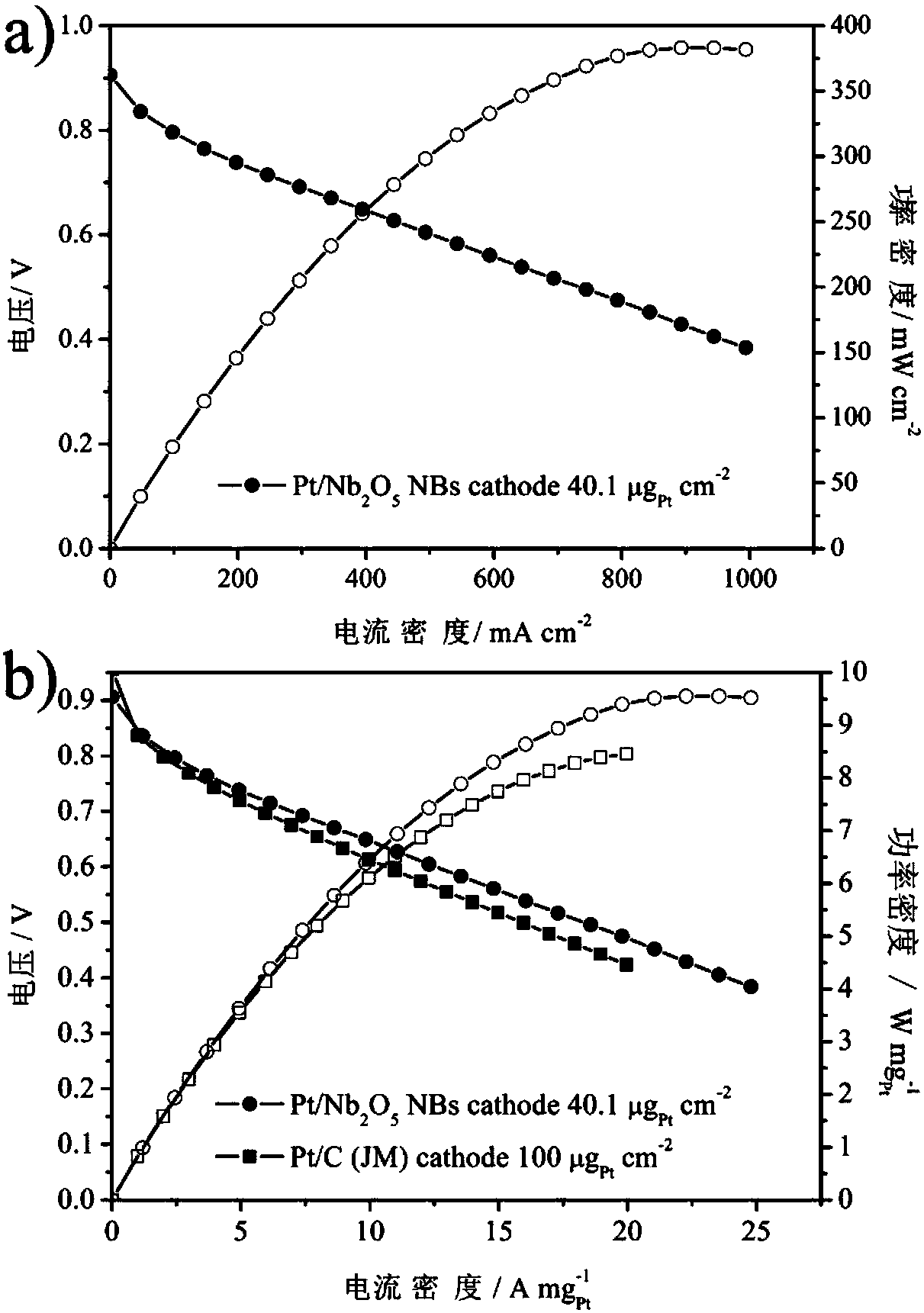

[0067] Co-OH-CO was deposited by magnetron sputtering 3 Nb loaded on the array 2 o 5 . The magnetron sputtering power is 100W, the sputtering time is 20min, and the operating pressure is 1.0Pa. Then magnetron sputtering method was used on Nb 2 o 5 The surface of the nanorod array was loaded with Pt, the ma...

Embodiment 2

[0074] Co-OH-CO 3 See Example 1 for the preparation of nanorod arrays.

[0075] Co-OH-CO was deposited by magnetron sputtering 3 Ta 2 o 5 . The magnetron sputtering power is 100W, the sputtering time is 20min, and the operating pressure is 1.0Pa. Then using magnetron sputtering method on Ta 2 o 5 The surface of the nanorod array was loaded with Pt, the magnetron sputtering power was 100W, the sputtering time was 10min, and the operating pressure was 1.0Pa. Figure 5 Shown is the prepared platinum-loaded Ta 2 o 5 SEM image of the nanorod array. It can be seen from the figure that Ta loaded with platinum 2 o 5 The nanorod array is perpendicular to the substrate, the length of the array is 2-5 μm, and the diameter of the nanorod is 100nm-200nm.

[0076] Will be loaded with platinum Ta 2 o 5 The nanorod array was transferred on one side of the ion exchange membrane, the transfer pressure was 10 MPa, the transfer temperature was 140° C., and the transfer time was 2 mi...

Embodiment 3

[0080] Co-OH-CO 3 See Example 1 for the preparation of nanorod arrays.

[0081] Co-OH-CO was deposited by magnetron sputtering 3 Nb loaded on the array 2 o 5 . The magnetron sputtering power is 100W, the sputtering time is 20min, and the operating pressure is 1.0Pa.

[0082] Prepare H at a concentration of 0.05M 2 IrCl 6 isopropanol solution, the Nb 2 o 5 Nanorod arrays were impregnated in the configured H 2 IrCl 6 In the isopropanol solution, control the immersion time to 3.0min and the immersion temperature to 25°C. After the impregnation is finished, take out the Nb 2 o 5 For nanorod arrays, absorb the remaining precursor solution on the surface and dry at room temperature. Nb impregnated with catalyst precursor 2 o 5 The nanorod array was placed in a tube furnace and calcined at 450°C for 1 hour to prepare the catalytic layer, and the calcining atmosphere was air.

[0083] Hot press the catalytic layer on 212 (DuPont) membrane, the transfer pressure was 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com