Metallic oxide coating electrode and manufacture method thereof

An oxide coating and metal technology, applied in the field of electrochemical engineering, can solve the problems of narrow electrode application range, short electrode life, and limited improvement of electrode life, and achieve strong anodic oxidation resistance, high electrocatalytic activity, and noble metal The effect of low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

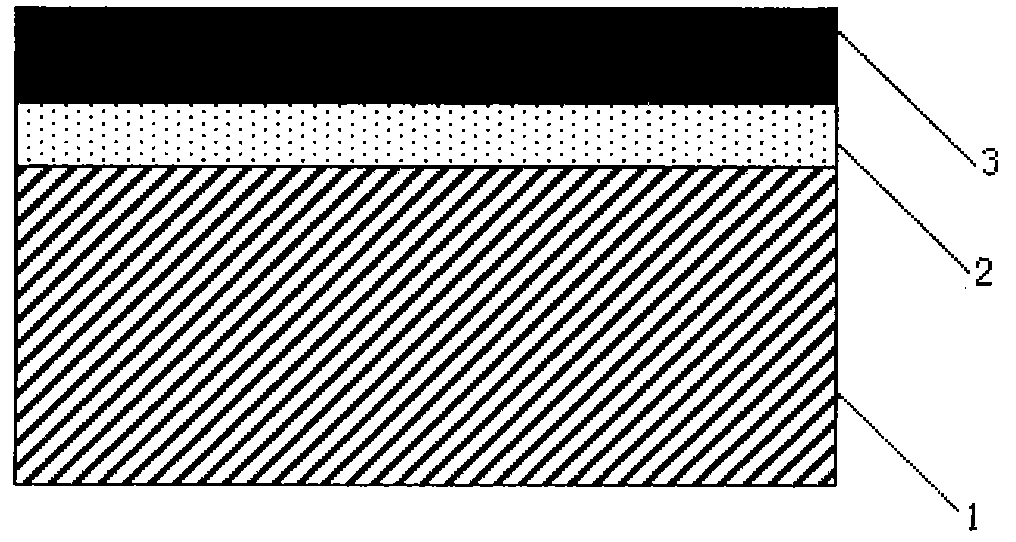

[0019] The structure of the metal oxide electrode of the present invention is as figure 1 As shown, it is coated with an intermediate layer 2 on the metal substrate 1, and coated with a metal oxide coating 3 on the intermediate layer 2; the metal substrate 1 is titanium, tantalum, niobium, zirconium, tungsten, aluminum or One of stainless steel; the intermediate layer 2 is prepared by impregnating the nano-powder of titanium-based cermet compound with a solution containing a platinum group metal compound to prepare an intermediate layer coating liquid, which is coated on the metal substrate, dried, oxidized The product obtained by thermal decomposition. The metal base 1 is treated with degreasing and acid etching. The middle layer 2 is a solution containing a platinum group metal compound impregnated with a nano-powder of a titanium-based cermet compound to form a middle layer coating liquid, which is coated on the metal substrate 1, and then oxidized and thermally decomposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com