A half-bridge igbt module with multiple chips connected in parallel

A multi-chip and chip technology, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of reduced reliability, high junction temperature, and current imbalance, and achieve the effect of reducing current differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

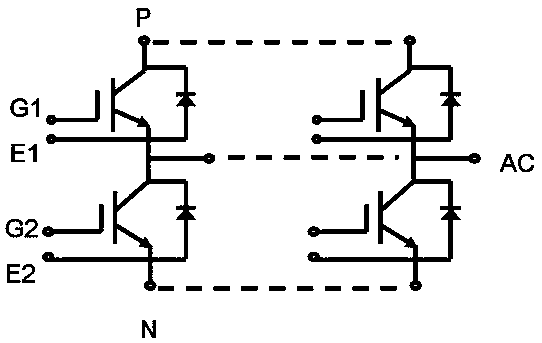

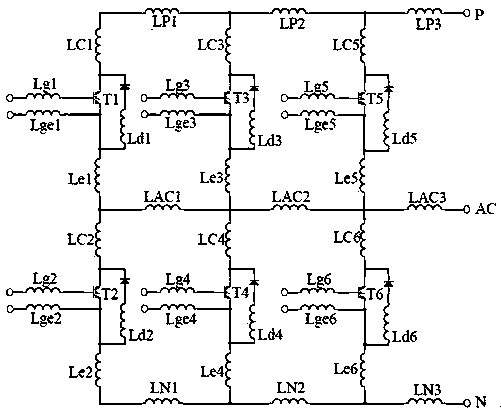

[0019] The purpose of the present invention is to balance the distributed inductance of the gate control loop and power loop of each chip inside the power module connected in parallel with multiple chips, so that when the module is turned on, the current borne by each chip is basically balanced, and the module is turned off when the module is turned on. When off, the voltage borne by each chip is basically balanced.

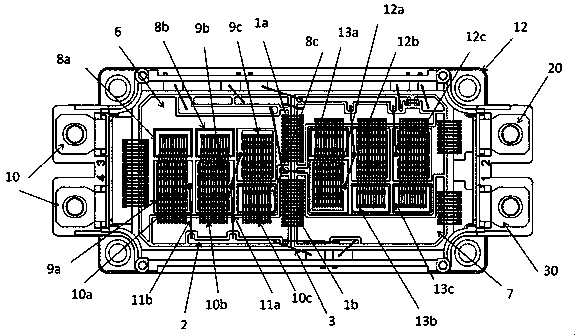

[0020] For the solution of the present invention, the following adjustments are made: a multi-chip parallel IGBT module structure with a heat-conducting bottom plate and a ceramic copper-clad ceramic substrate, as well as chips on the substrate and interconnected bonding wires. The module sequentially includes from the back: metal base plate 12, ceramic copper-clad base plate (DBC) 6, 7, IGBT chips 9a, 9b, 9c, 12a, 12b, 12c; and FRD chips 10a, 10b, 10c, 13a, 13b , 13c, and bonding wires connecting the chip, DBC, and terminals. Among them, IGBT 9c and IGBT 12a ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com