Field emission type display panel

A display panel and field emission technology, applied in image/graphic display tubes, cathode ray tubes/electron beam tubes, discharge tubes, etc., can solve problems such as insufficient uniformity of luminous brightness, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

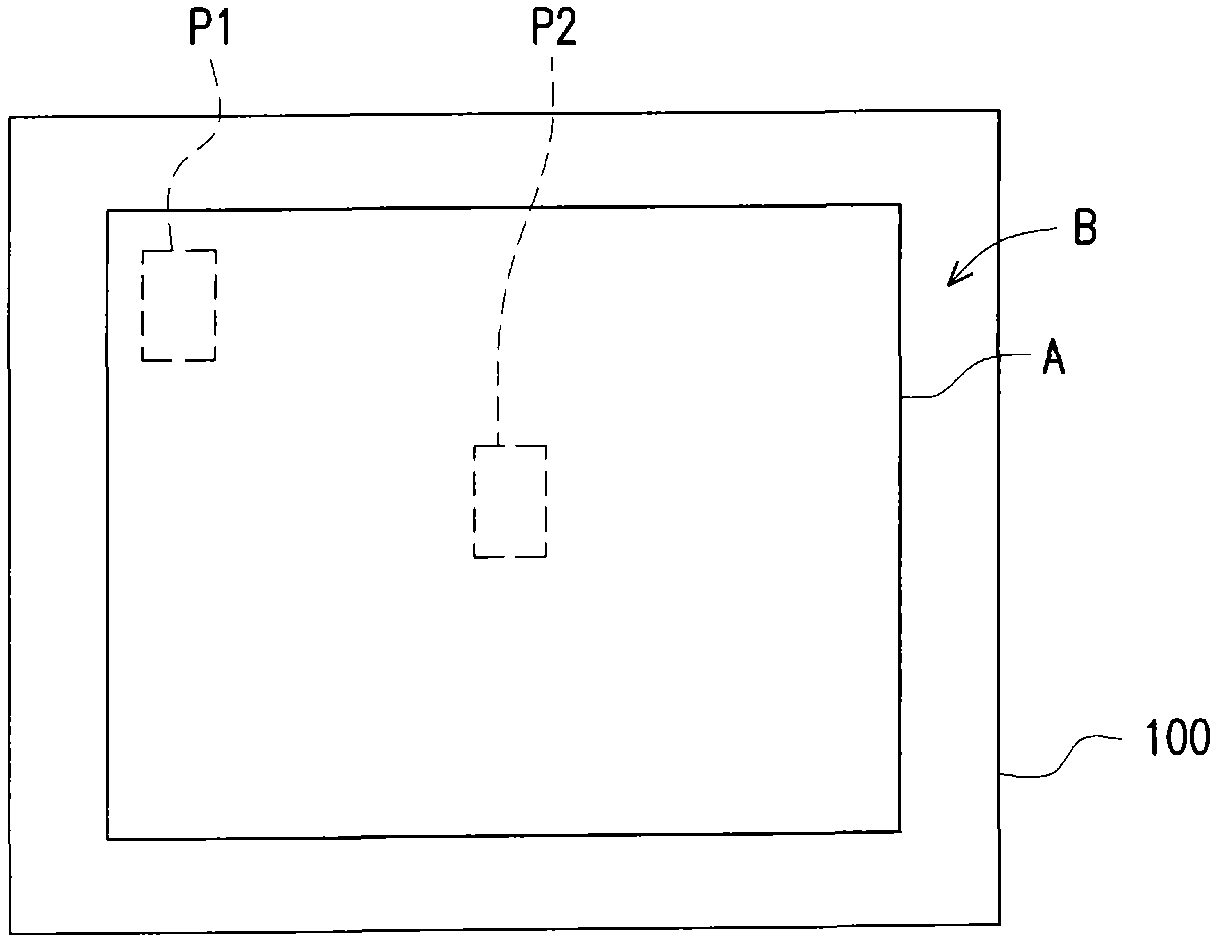

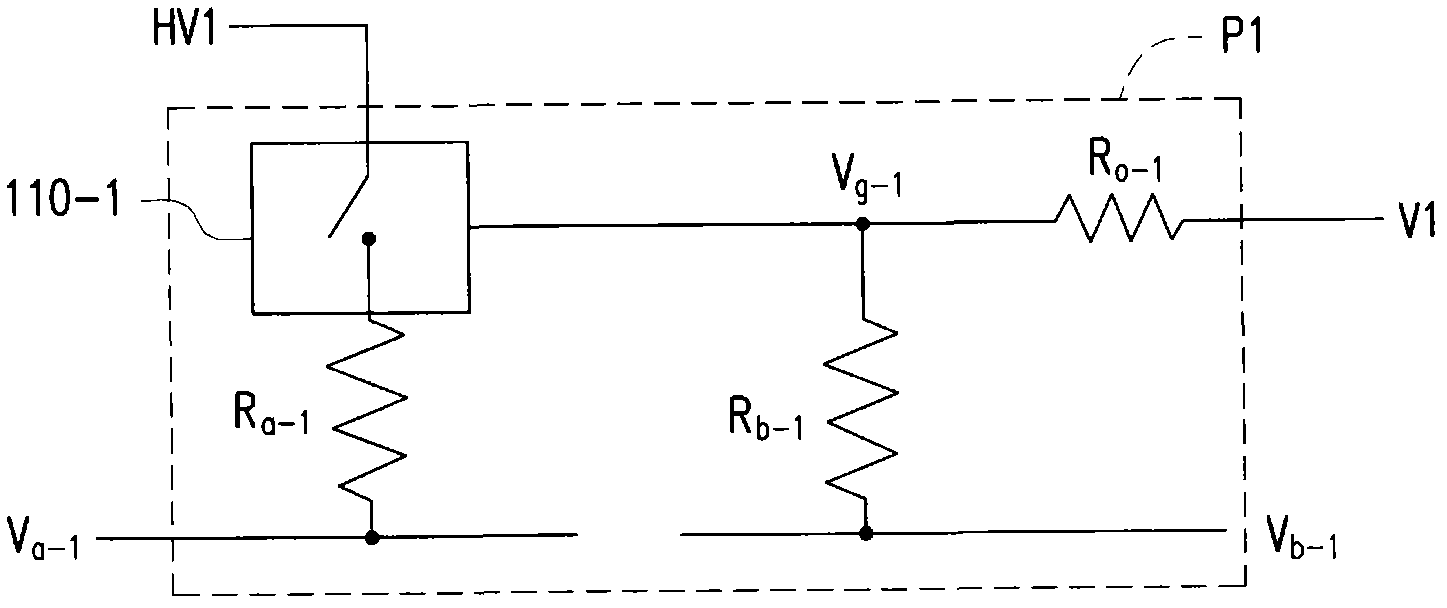

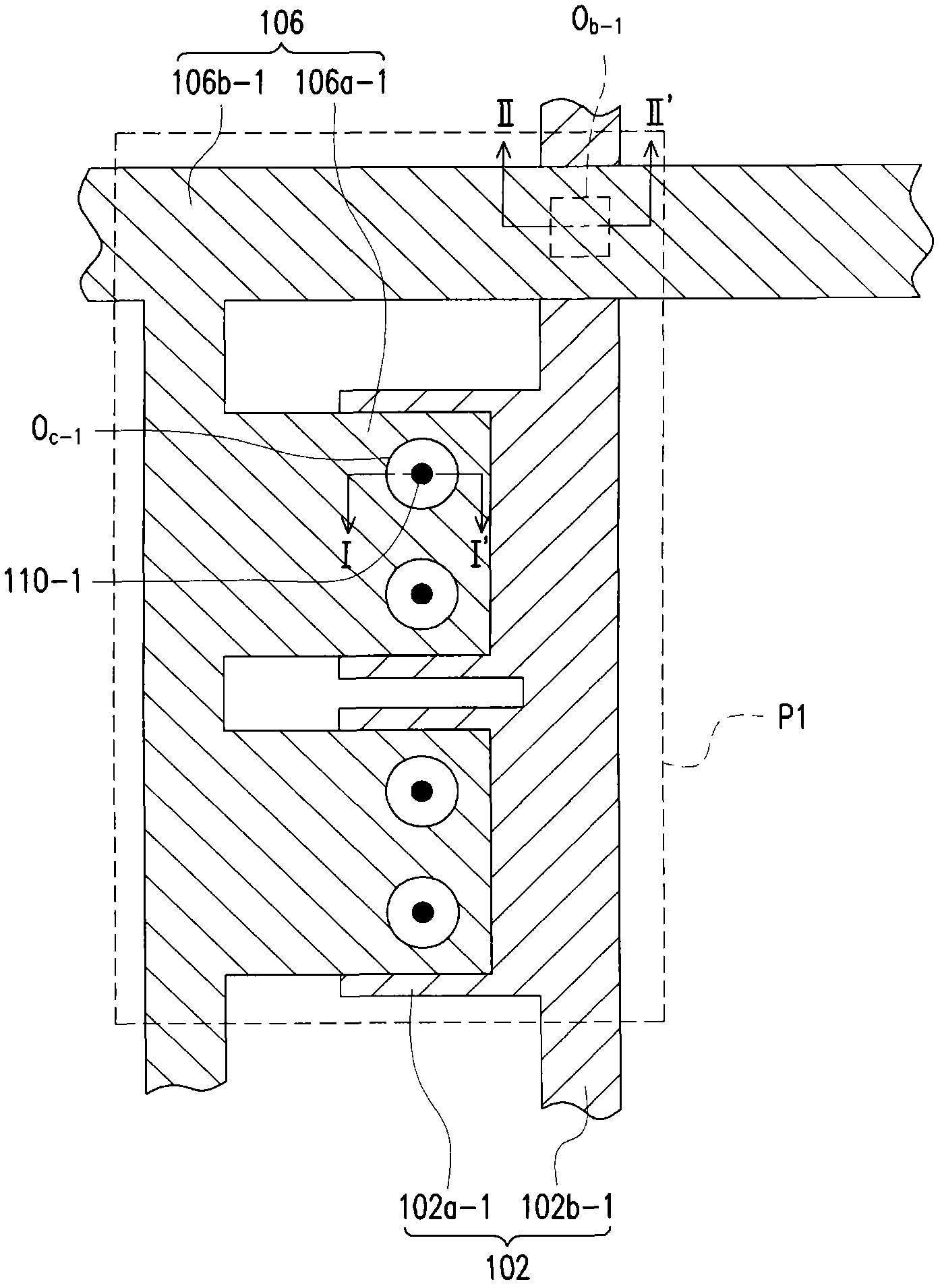

[0074] In the field emission display panel of this example, each sub-pixel area is provided with a first resistance element and a second resistance element. The structure of the sub-pixel area of the field emission display panel of this example is as follows Figure 2A-Figure 2C or Figure 3A-Figure 3C Shown. In addition, in this example, the voltage applied to each sub-pixel area by the external circuit is about 35V, the resistance value of the external circuit is about 3KΩ, and the first conductive layer 102 (the first electrode and the first electrode line) is given about 0V. . When electrical measurements are performed on three of the sub-pixel regions (sub-pixel regions 1, 2, and 3) of the field emission display panel of this example, the results shown in Table 1 can be obtained.

[0075] Table 1

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com