Functional ink for ink-jet printing as well as preparation method and application

An inkjet printing and ink technology, applied in the direction of copying/marking method, application, printing, etc., can solve the problems of high cost of nozzle and ink import, blurred glaze color, poor printing texture effect, etc., to meet the needs of industrial automation in large quantities. Production, product use safety, the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Embodiment: the preparation of functional ink

[0059] Preparation of functional ink (1)

[0060] Weigh 100g of the mixed component of epoxy resin 1# (E03:E14=3:2), grind it into powder with a mortar, pour it into a 1000ml beaker, and then add solvent 1# (toluene:acetone=1:4) 400g is fully dissolved to obtain a uniform viscous liquid; add curing agent (diaminodiphenylmethane) to 60g, after stirring evenly, add solvent 2# (ethylene glycol methyl ether) 80g while stirring to ensure that the system is always uniform For clarified solution, heat the above system at 50°C and stir slowly for 12 hours, then add 180g of epoxy resin 2# (F44) until it is completely dissolved, then add 9g of accelerator (2E4MZ) until it is completely dissolved, and finally add additives (flow The leveling agent Digo 100 is 0.2g, the antioxidant Chemtura 1076 is 0.3g, and the adhesion promoter Digo LTW is 0.1g).

Embodiment 2

[0061] Embodiment 2: Preparation of UV printing finished product

[0062] Printed product (a)

[0063] Degrease, dust and dry the surface of the glass sheet, spray the water film on the surface of the glass sheet with an aqueous solution of coupling agent Dow Corning 6121 (0.1-0.5%), scrape off and dry (activate), apply the functional ink (1) Fill it into the transparent ink channel of the 3D printer 1024UVHS of DCS Company in the United States (the ink in other channels is the original UV ink), print graphics and texts with transparent ink on the activated glass sheet and dry to ensure that the solvent is completely evaporated, and print color graphics and texts on the transparent ink layer And UV curing, put the printed material into the oven and bake at 160°C for 30 minutes.

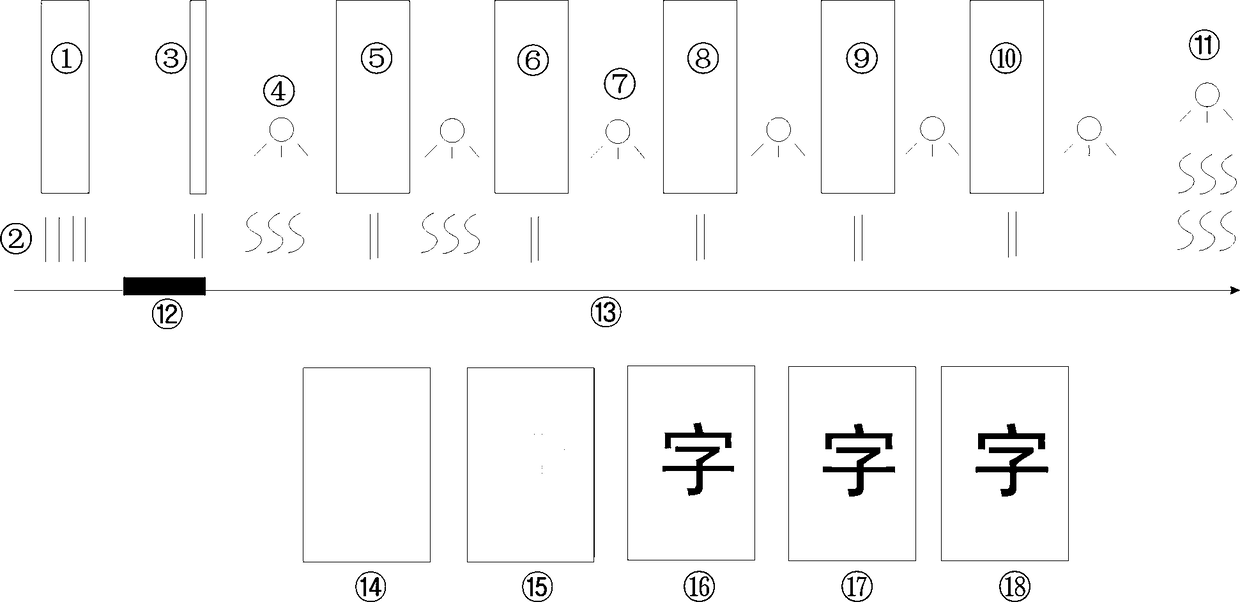

[0064] figure 1 The functional ink ultraviolet curing inkjet printing method of the present invention is shown in the form of a process flow. The glass sheet 12 after oil removal, dust removal, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com