Novel machine part polishing device

A new technology for mechanical parts, applied in the field of new mechanical parts grinding devices, can solve the problems of reducing work efficiency, easy movement, wasting time and manpower, etc., and achieve the effect of reducing processing costs, improving work efficiency, and quickly and intelligently cooling down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

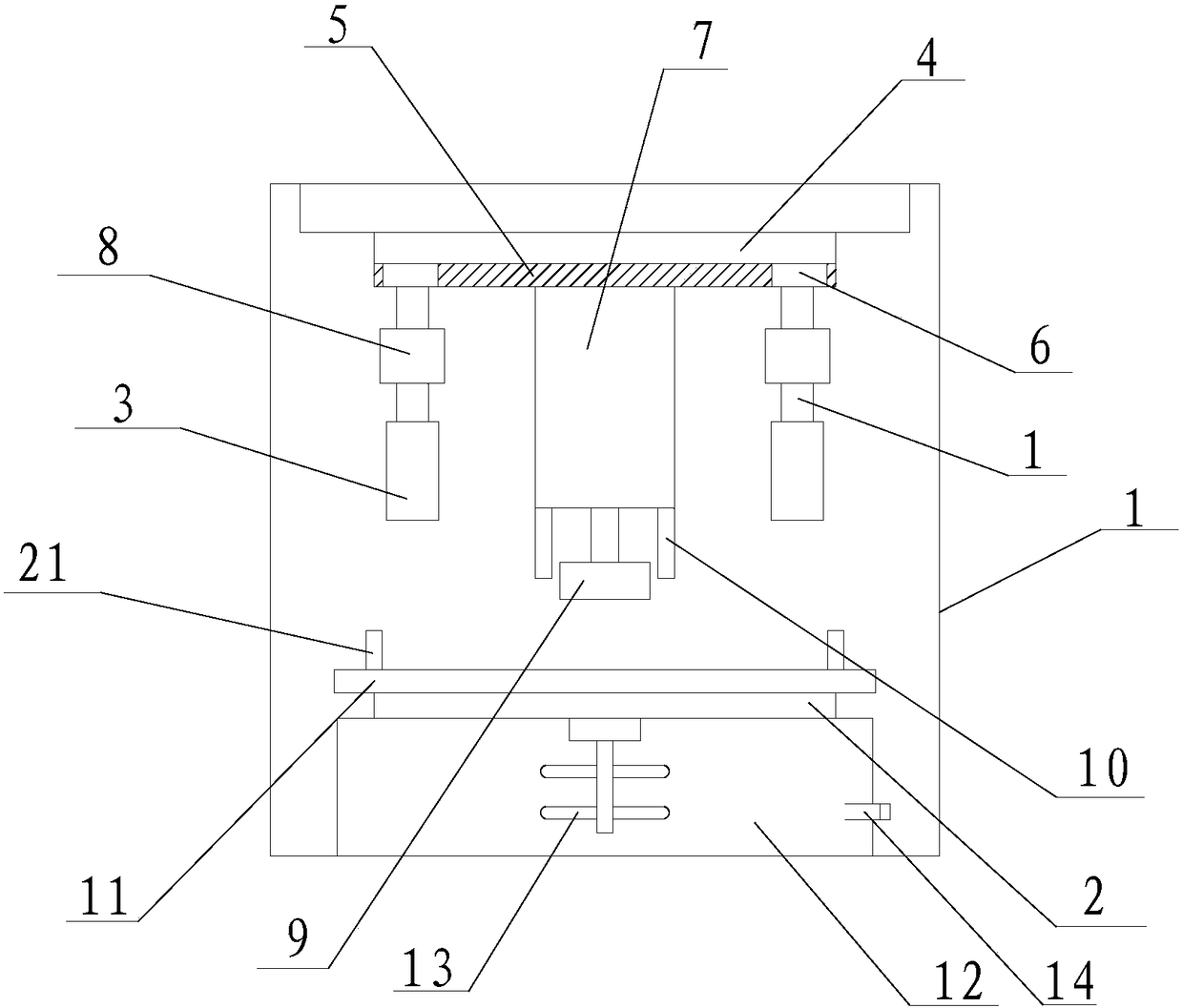

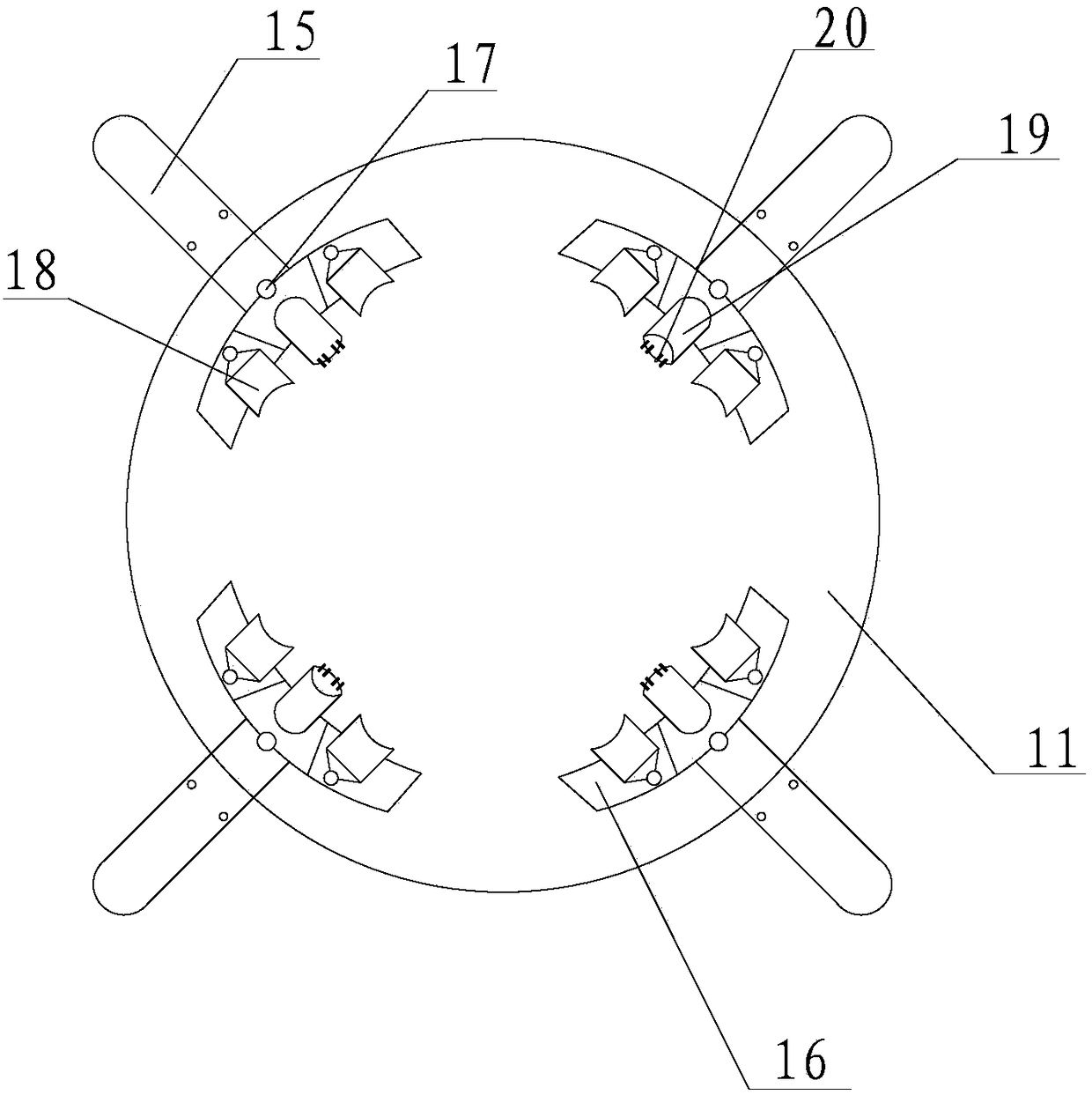

[0021] like figure 1 , figure 2 As shown, a new type of grinding device for mechanical parts of the present invention includes a housing 1, a grinding table 2, and a grinding mechanism 3. The inner top of the housing 1 is provided with a lifting platform 4, and the lifting platform 4 is provided with a slide rail 5. The slide rail 5 is provided with a slide block 6 and a fixing device 7 cooperating with it, the lower end of the slide block 6 is fixedly connected to a motor 8 and a grinding mechanism 3, and the front end of the fixing device 7 is provided with a fixed end 9, and the A vacuum cleaner 10 is provided on both sides of the fixed end 9, a grinding table 2 is provided directly below the grinding mechanism 3, a clamping disc 11 is provided on the upper end of the grinding table 2, and a storage material is provided inside the grinding table 2. cavity 12, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com