Porous magnesium silicate composite adsorption film and preparation method thereof

A composite adsorption, magnesium silicate technology, applied in the direction of magnesium silicate, silicate, silicon compounds, etc., can solve the problems of increasing risk, limiting the scope of use of materials, single carrier, etc., achieving easy operation and broad market application prospects , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

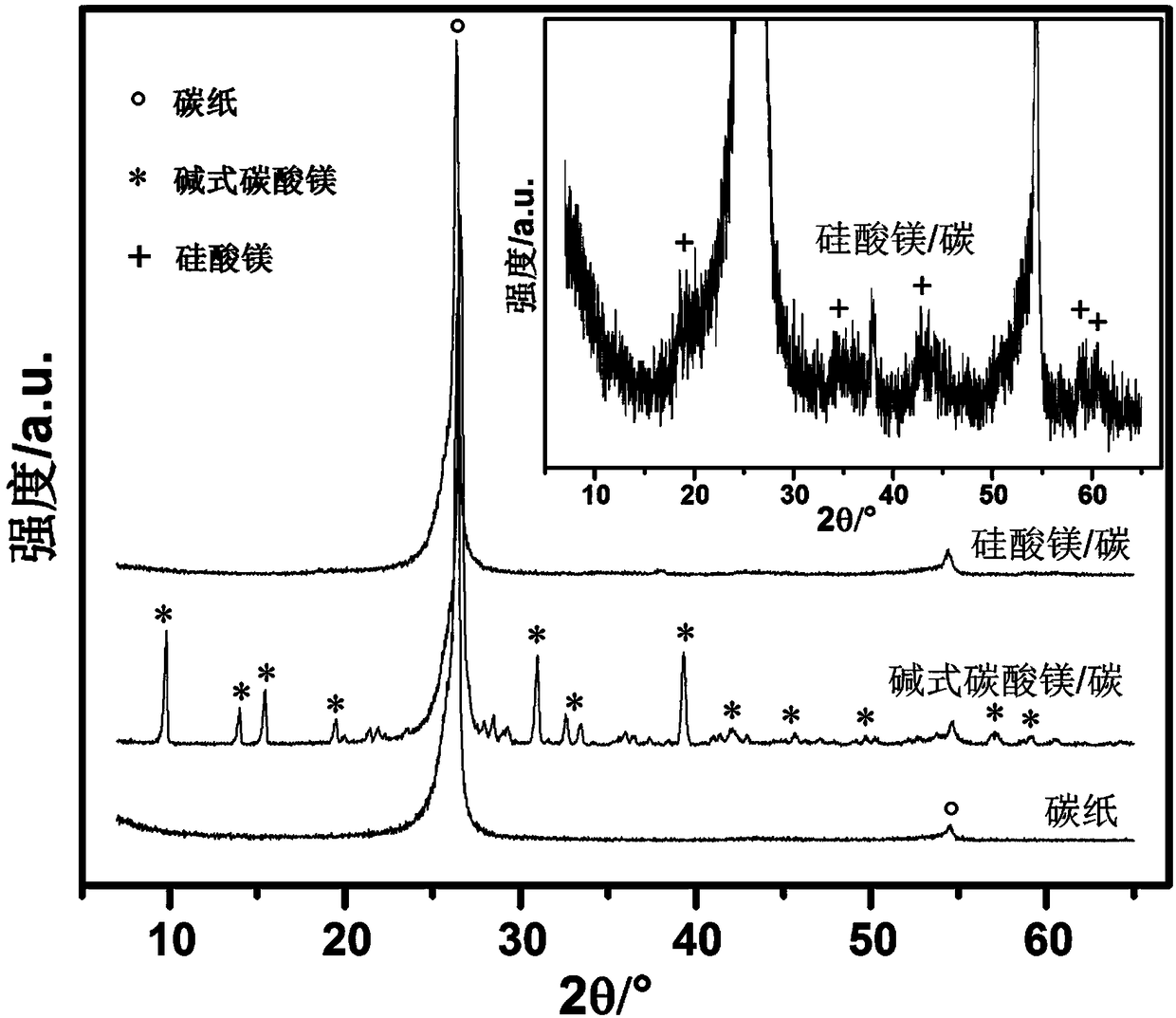

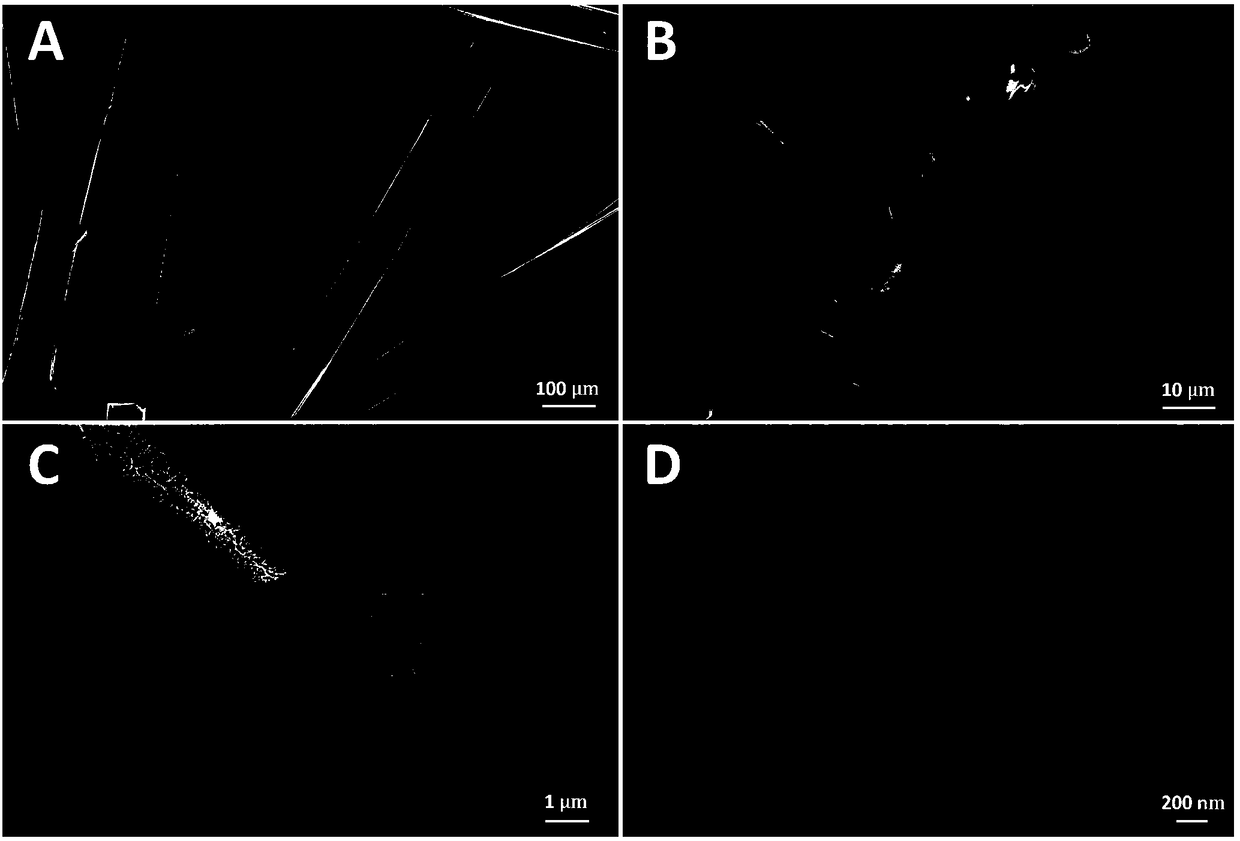

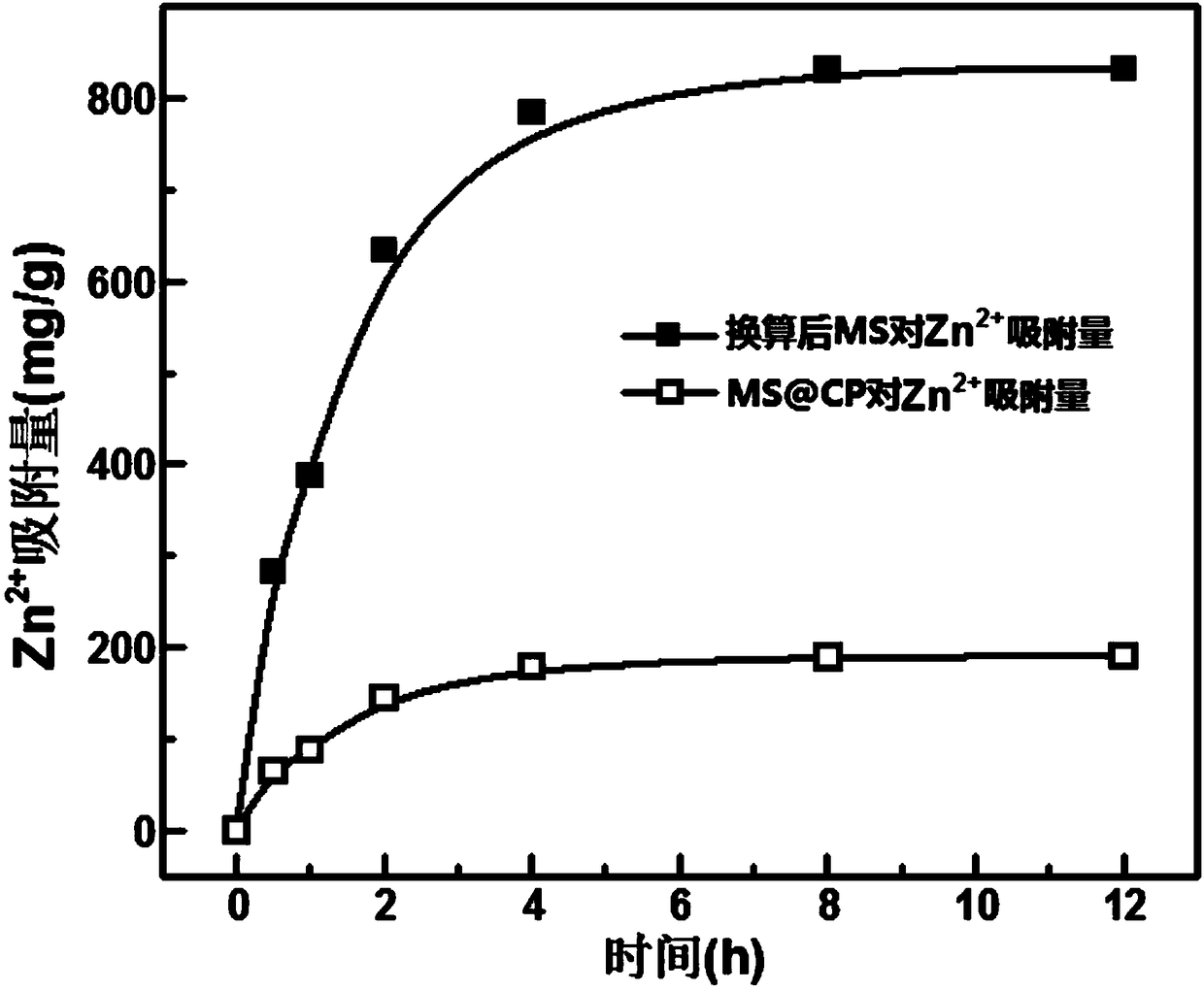

[0027] The base material in this embodiment is carbon fiber material, preferably carbon paper. Of course, those skilled in the art know that the carbon fiber material here is not limited to carbon paper, and all carbon fiber materials that can realize the present invention are included, such as carbon cloth, graphene, carbon nanotube products and the like.

[0028] Step A: Soak the carbon paper in concentrated nitric acid solution for 2-6h, preferably 6h, to fully modify the surface, wash the surface with water, and then place it in an oven at 60-80°C for 10-30min, preferably at 80°C Dry for 15min;

[0029] Step B: 0.4 g (1.6 mmol) MgSO 4 ·7H 2 O and 2.4g (17.1mmol) of hexamethylenetetramine were dissolved in 50mL of deionized water to prepare a mixed solution with magnesium and alkali concentrations of 0.032mol / L and 0.342mol / L, respectively. In the mixed solution, and sonicated for 10-30min, preferably 30min, transfer the sonicated carbon paper and the solution together i...

Embodiment 2

[0033] The base material in this embodiment is a polymer material, preferably polyvinyl fluoride. Of course, those skilled in the art know that the polymer material here is not limited to polyvinyl fluoride, and any polymer material that can realize the present invention is included, such as epoxy resin, phenolic plastic, polyacrylonitrile fiber, and the like.

[0034] Step A: Soak the polyvinyl fluoride film in concentrated nitric acid solution for 2-6 hours, preferably 2 hours, to fully modify the surface, wash the surface with water, and then dry it in an oven at 60-80°C for 10-30 minutes, preferably at 60 ℃ oven drying for 30min;

[0035] Step B: 0.7g (3.4mmol) MgCl 2 ·6H 2 O is dissolved in 50mL deionized water together with 4.8g (34.2mmol) hexamethylenetetramine and is mixed with magnesium and alkali concentration and is the mixed solution of 0.064mol / L and 0.684mol / L respectively, gets the gained polyvinyl fluoride film of step A 3×3cm placed in the mixed solution, a...

Embodiment 3

[0039] The base material in this embodiment is a ceramic material, preferably alumina ceramics. Certainly, those skilled in the art know that the ceramic materials here are not limited to alumina ceramics, and all ceramic materials that can realize the present invention are included, such as magnesia porcelain, steatite porcelain, and the like.

[0040] Step A: Soak alumina ceramics in concentrated sulfuric acid solution for 2-6 hours, preferably 4 hours, to fully modify the surface, wash the surface with water, and dry in an oven at 60-80°C for 10-30min, preferably in an oven at 80°C Dry for 30min;

[0041] Step B: 0.4g (1.6mmol) Mg(NO 3 ) 2 ·6H 2 O and 2.1g (34.2mmol) urea were dissolved in 50mL deionized water to prepare a mixed solution with concentrations of magnesium and alkali of 0.032mol / L and 0.684mol / L respectively, and 3×3cm of alumina ceramics obtained in step A were placed in the mixing solution. solution, and ultrasonic 5 ~ 30min, preferably 20min. Transfer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com