Method for determination of content of nitrite in jam

A nitrite and jam technology, which is applied in the preparation of test samples and the measurement of color/spectral properties, etc., can solve the problems that need to be improved, and achieve the effects of strong accuracy, low detection limit and high recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In this embodiment, measure the nitrite content in the jam according to the following steps:

[0056] 1. Weigh 10g of jam (accurate to 0.01g) to make a homogenized sample group (if water is added during the preparation process, it should be converted according to the amount of water added, ignoring the error caused by the density of jam, and 10g of sample is converted into 10ml of water for conversion), blank The group without jam was placed in a 300ml Erlenmeyer flask, each with 10mL of saturated borax solution, and stirred evenly. The sample group was added with 160ml of water at about 70°C, and the blank group was added with 170ml of water at about 70°C, mixed evenly, and placed in boiling water. Heated in a bath for 15 minutes, then placed in a cold water bath to cool, and left to room temperature to obtain an extract.

[0057] 2. Extraction purification

[0058] The extracts of the sample group and the blank group were subjected to the following operations:

[00...

Embodiment 2

[0067] In this example, recovery was determined as follows:

[0068] (1) Mix 10 grams (accurate to 0.01g, without sodium nitrite) jam with sodium nitrite standard solution and set the volume to 200mL to obtain a spiked sample, wherein, according to the added sodium nitrite standard solution, the nitrite The sodium content is converted into the sodium nitrite content in the spiked sample, which is recorded as the theoretical content;

[0069] (2) detect the sodium nitrite content in the standard-added sample according to the method of embodiment 1, record as measured content;

[0070] (3) Calculate the recovery rate according to the formula recovery rate (%)=100×measured content / theoretical content.

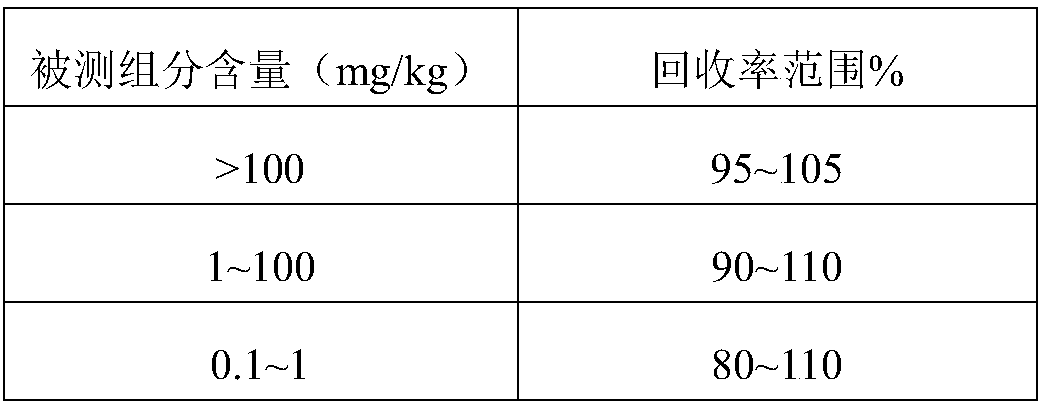

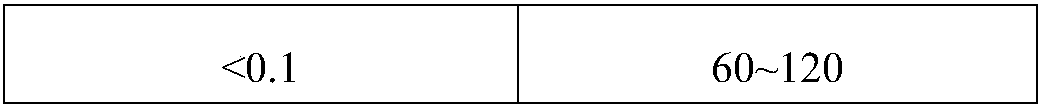

[0071] F.1 of GB / T 27404-2008 "Laboratory Quality Control Specifications for Food Physical and Chemical Testing" gives the content of the tested components and the corresponding recovery range values that meet the requirements, see Table 1 for details.

[0072] Table 1 GB / T 27...

Embodiment 3

[0080] The recovery rate of the nitrite content in the jam was determined according to the method of Example 2, the difference being that in step 3 of Example 1, after adding the p-aminobenzenesulfonic acid solution and mixing, the standing time was 5 minutes.

[0081] The results are shown in Table 3. When the p-aminobenzenesulfonic acid solution was left standing for 5 minutes, the recovery rate was in the range of 80-110%.

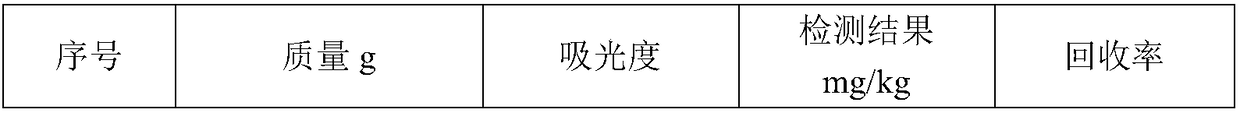

[0082] Table 3 adds the influence of p-aminobenzenesulfonic acid solution standing time (5min) on detection results

[0083] serial number

[0084] Note: Serial numbers 2 to 7 represent parallel samples

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com