A high-temperature anti-oxidation coating for tungsten-rhenium thermocouple and its application

An anti-oxidation coating, thermocouple technology, applied in the direction of coating, thermometer with directly sensitive electrical/magnetic components, metal material coating process, etc., can solve the use limitation, thermocouple armor volume and weight Increase, no actual use of the product and other problems, to achieve the effect of fast temperature response, long anti-oxidation time, and increased adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

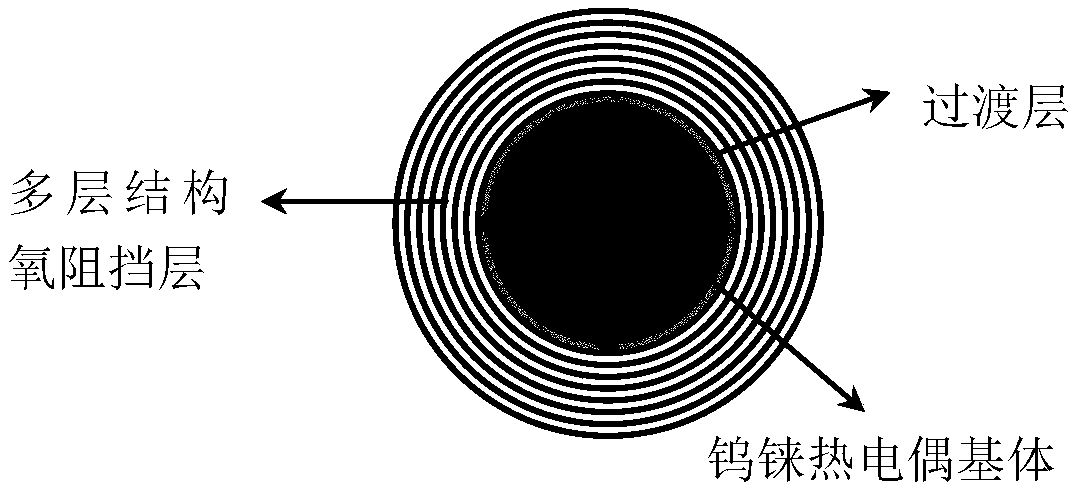

[0059] A high-temperature oxidation-resistant coating structure for a tungsten-rhenium thermocouple, including a transition layer and an oxygen barrier layer. There is a TaC transition layer with a thickness of about 20 μm between the oxygen barrier material and the tungsten-rhenium thermocouple substrate, that is, the surface of the tungsten-rhenium thermocouple wire with a diameter of about 0.5 mm, such as figure 1 As shown, the oxygen barrier layer has seven layers in total, the first layer is HfC-10%ZrC material, the coefficient of thermal expansion is 6×10 -6 K -1 , the thickness is 20μm; the second layer is HfC-30%ZrC material, the thickness is 20μm; the third layer is HfC-50%ZrC, the thickness is 20μm; the fourth layer is ZrC, the thermal expansion coefficient is 7.3×10 -6 K -1 , a thickness of 20 μm; the fifth layer is ZrC-10% ZrO2, a thickness of 20 μm; the sixth layer is ZrC-30ZrO2, a thickness of 20 μm; the seventh layer is ZrC-50ZrO2, a thickness of 20 μm. The t...

Embodiment 2

[0066]A high-temperature oxidation-resistant coating structure for a tungsten-rhenium thermocouple, including a transition layer and an oxygen barrier layer. There is a Ta transition layer with a thickness of about 15 μm between the oxygen barrier material and the tungsten-rhenium thermocouple substrate, that is, the surface of the tungsten-rhenium thermocouple wire with a diameter of about 0.5 mm. The oxygen barrier layer has six layers in total, the first layer is made of SiC material with a thermal expansion coefficient of 4.5×10 -6 K -1 , the thickness is 20μm; the second layer is SiC-20%HfC material, the thickness is 20μm; the third layer is SiC-40%HfC, the thickness is 20μm; the fourth layer is SiC-60%HfC, the thickness is 20μm; The layer is SiC-80%HfC with a thickness of 20μm; the sixth layer is HfC with a thermal expansion coefficient of 6.7×10 -6 K -1 , with a thickness of 20 μm. The total thickness of the oxygen barrier material of the multilayer structure is 120...

Embodiment 3

[0073] A high-temperature oxidation-resistant coating structure for a tungsten-rhenium thermocouple, including a transition layer and an oxygen barrier layer. There is a WSi2 transition layer with a thickness of about 20 μm between the oxygen barrier material and the tungsten-rhenium thermocouple substrate, that is, the surface of the tungsten-rhenium thermocouple wire with a diameter of about 0.5 mm. The oxygen barrier layer has eleven layers in total, the first layer is made of HfO2 material with a thermal expansion coefficient of 4.3×10 -6 K -1 , a thickness of 20 μm; the second layer is HfO2-10% YSZ (yttrium stabilized zirconia, molar ratio Y:Zr=6:100) material, a thickness of 20 μm; the third layer is HfO2-20% YSZ, a thickness of 20 μm; The fourth layer is HfO2-30%YSZ, the thickness is 20μm; the fifth layer is HfO2-40%YSZ, the thickness is 20μm; the sixth layer is HfO2-50%YSZ, the thickness is 20μm; the seventh layer is HfO2-60% YSZ, the thickness is 20 μm; the eighth l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com