Leaching method of zinc replacement slag

A technology of leaching and leaching solution, applied in the field of leaching of zinc replacement slag, can solve the problems of low leaching rate of valuable metals, dispersion of valuable metals, and high cost of construction, and achieves the advantages of reducing leaching difficulty, high leaching rate, and reducing treatment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

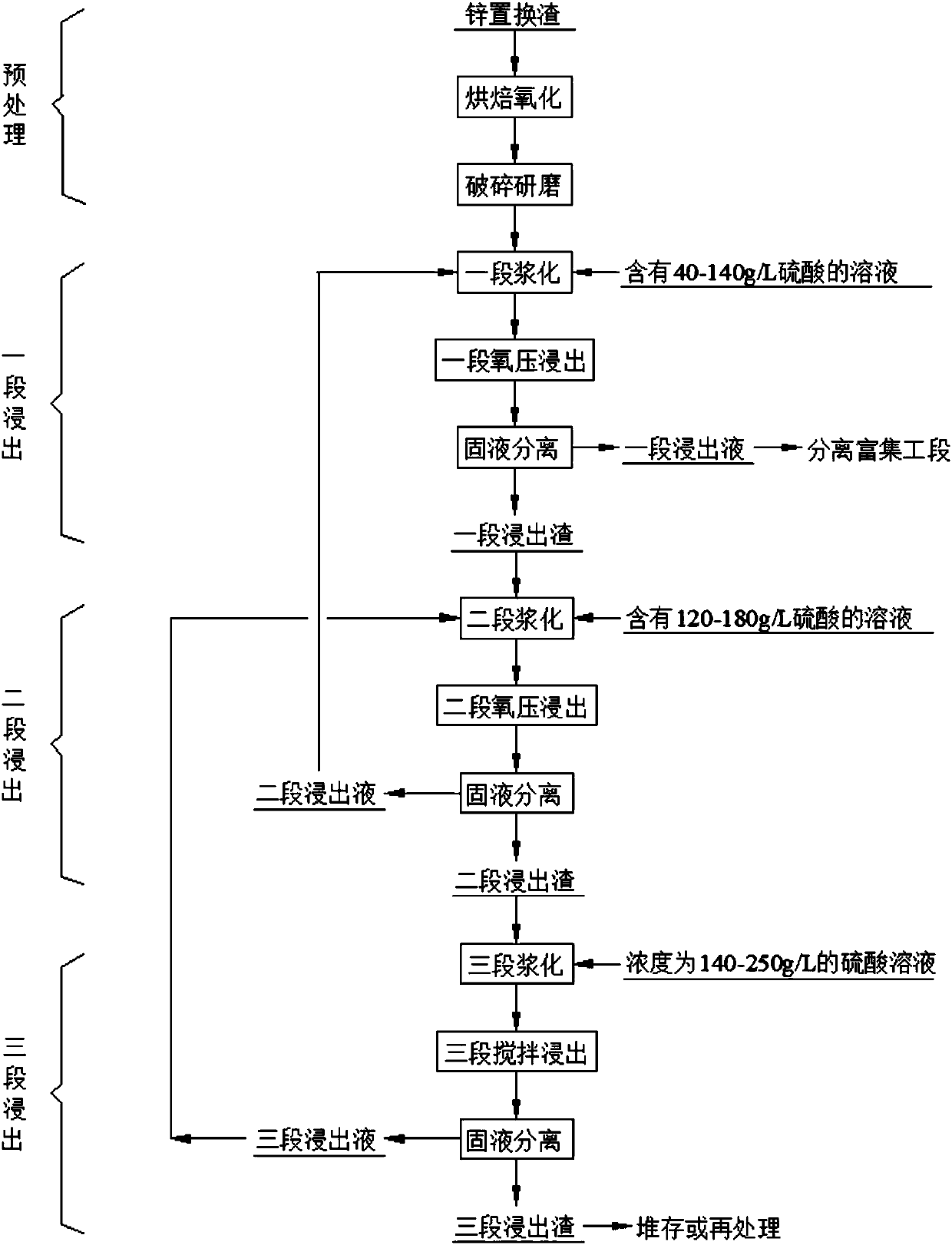

[0041] Such as figure 1 As shown, in this embodiment, the zinc replacement slag is leached, and the zinc replacement slag contains 0.45% gallium, 0.45% germanium, 0.1% indium, 8% copper, 16.9% zinc, 3% iron, dioxide Silicon 10.3%, the specific steps are as follows:

[0042] (1) Pretreatment: bake the zinc-substituted slag in an oxygen-containing atmosphere at a temperature of 300° C. for 2 hours. After baking, use a grinder to grind to a particle size of 200 mesh for later use.

[0043] (2) One-stage leaching: For every 1 kg of pretreated zinc replacement slag, use 3 liters of a solution containing 100g / L sulfuric acid or the second-stage leaching solution for slurrying. Then pump the slurried slurry into the oxygen autoclave for leaching, and the oxygen flow rate in the oxygen autoclave is 20-120Nm 3 / h, the pressure in the kettle is 0.2Mpa, the leaching temperature is 80°C, and the leaching time is 2 hours. Then the leaching slurry is separated from solid to liquid to obt...

Embodiment 2

[0048] Such as figure 1 As shown, in this embodiment, the zinc replacement slag is leached, and the zinc replacement slag contains 0.55% gallium, 0.26% germanium, 0.6% indium, 6% copper, 19.5% zinc, 5% iron, dioxide Silicon 11.3%, the specific steps are as follows:

[0049] (1) Pretreatment: bake the zinc-substituted slag in an oxygen-containing atmosphere at a temperature of 500° C. for 4 hours. After baking, use a grinder to grind the slag to a particle size of 200 mesh for later use.

[0050] (2) One-stage leaching: Slurry with 4 liters of solution containing 140g / L sulfuric acid or two-stage leaching solution for every 1 kg of pretreated zinc replacement slag. Then pump the slurried slurry into the oxygen autoclave for leaching, and the oxygen flow rate in the oxygen autoclave is 20-120Nm 3 / h, the pressure in the kettle is 0.2Mpa, the leaching temperature is 80°C, and the leaching time is 2 hours. Then the leaching slurry is separated from solid to liquid to obtain a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com