Electrostatic-screening graphene anticorrosion coating and preparation method thereof

A technology of electrostatic shielding and anti-corrosion coatings, applied in anti-corrosion coatings, conductive coatings, polyether coatings, etc., can solve problems such as mechanical properties, anti-corrosion performance degradation, graphene easy to re-overlap and gather, destroy uniformity, and compactness, etc., to achieve Improve stability, improve electrostatic shielding effect and stability, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

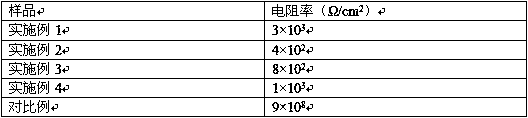

Examples

Embodiment 1

[0025] An electrostatic shielding graphene anticorrosive coating, comprising the following parts by weight: 65 parts by weight of polyvinylidene fluoride-tetrafluoroethylene-perfluoromethyl vinyl ether emulsion, 15 parts by weight of electrostatic shielding agent, and 15 parts by weight of gold nanowires , 5 parts by weight of sodium tripolyphosphate, 8 parts by weight of aminopropyltriethoxysilane, 2 parts by weight of polyoxypropylene glycerol ether, 3 parts by weight of BYK 354.

[0026] The preparation method of the electrostatic shielding graphene anticorrosive coating includes the following steps:

[0027] Place the porous carbon microspheres and the surfactant stearic acid in the dispersion of graphene oxide, ultrasonically disperse for 10-30 minutes, and then dry, and then spray the polyacetylene on the surface of the porous microspheres with a spray dryer. After drying, Get electrostatic shielding agent;

[0028] Mix the polyvinylidene fluoride-tetrafluoroethylene-perfluoro...

Embodiment 2

[0032] An electrostatic shielding graphene anticorrosive coating, comprising the following parts by weight: 75 parts by weight of polyvinylidene fluoride emulsion, 20 parts by weight of electrostatic shielding agent, 10 parts by weight of carbon black, 8 parts by weight of sodium tripolyphosphate, and diethylene triamino acid 3 parts by weight of propyltrimethoxysilane, 3 parts by weight of polyoxypropylene glyceryl ether, and 9 parts by weight of BYK 348.

[0033] The preparation method of the electrostatic shielding graphene anticorrosive coating includes the following steps:

[0034] Place the porous polystyrene microspheres and the surfactant fatty alcohol sodium sulfate in the dispersion of graphene oxide, ultrasonically disperse for 10-30 minutes, and then dry, then spray the polyacetylene on the surface of the porous microspheres with a spray dryer, and dry Then, the electrostatic shielding agent is obtained; the amount of sodium sulfate of fatty alcohol is 5% of the mass of...

Embodiment 3

[0039] An electrostatic shielding graphene anticorrosive coating, comprising the following parts by weight: 80 parts by weight of polyurethane emulsion, 25 parts by weight of electrostatic shielding agent, 5 parts by weight of silver nanoparticles, 8 parts by weight of polyacrylamide, and aminopropyl triethoxy 3 parts by weight of silane, 5 parts by weight of polyoxyethylene polyoxypropanolamine ether, 3 parts by weight of BYK 346;

[0040] The preparation method of the electrostatic shielding graphene anticorrosive coating includes the following steps:

[0041] Place the porous ceramic microspheres and fluorocarbon surfactant in the dispersion of graphene oxide, ultrasonically disperse for 10-30 minutes, and then dry, and then spray the polyacetylene on the surface of the porous microspheres with a spray dryer. After drying, the result is Electrostatic shielding agent;

[0042] Mix polyurethane emulsion, silver nanoparticles, polyacrylamide, aminopropyltriethoxysilane, polyoxyethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com