Sponge silicon powder and its preparation method and lithium ion battery

A sponge-like, silicon powder technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of unfavorable process treatment, difficult to control the particle size of nano-silicon powder, high raw material cost, and achieve large initial charge and discharge coulombs. Efficiency, reducing the risk of oxidative ignition, promoting the effect of diffusion reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the present disclosure, the primary particle size refers to the size of a single silicon crystal grain.

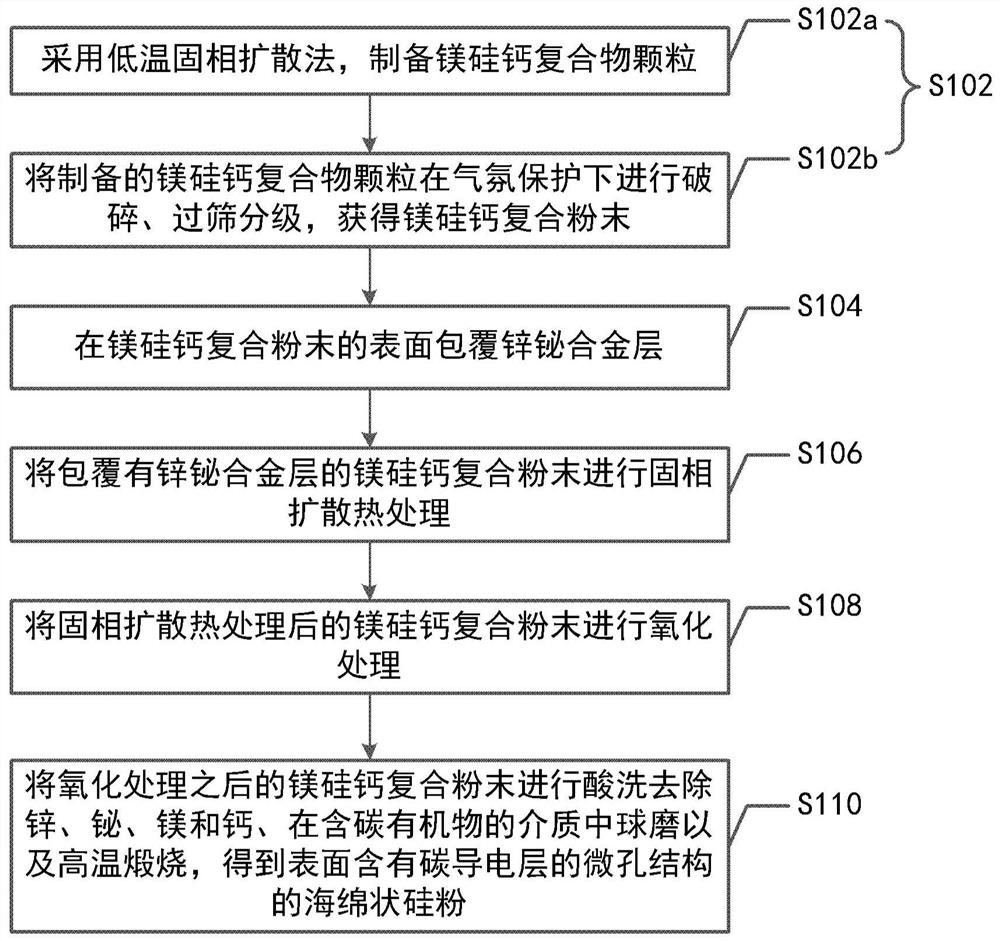

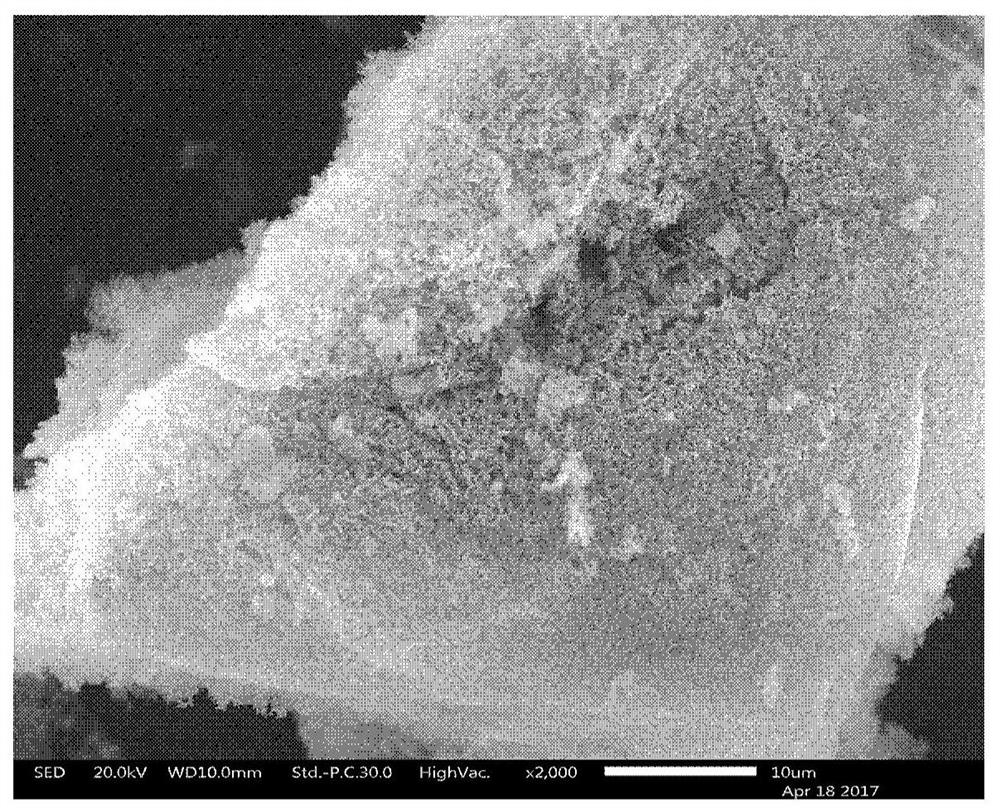

[0026] The disclosure provides a spongy silicon powder and its preparation method, and a lithium-ion battery. The low-temperature solid-phase diffusion method is used to overcome the safety risks of the magnesium powder dust in the workshop that is easy to catch fire and explode in the prior art, and is suitable for industrialized mass production. , and the prepared spongy silicon powder has a microporous structure, with a carbon conductive layer on the surface, uniform micropores, high crystallinity of silicon particles, and an overall oxygen content of less than 5%, which is better than porous silicon powder prepared by other existing technologies. Silicon powder; it is used in the negative electrode material of lithium-ion batteries, which has good conductivity and has a large first-time charge and discharge Coulombic efficiency.

[0027] In order to make the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com