Drug-release controlled dry suspension containing medical resin compound and preparation method thereof

A dry suspension and compound technology, applied in the field of pharmaceutical preparations, can solve the problems of single dosage form and increased workload of skeleton-type sustained-release preparations, and achieve the effects of fast drug release, low equipment requirements, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: preparation of drug-ion exchange resin complex

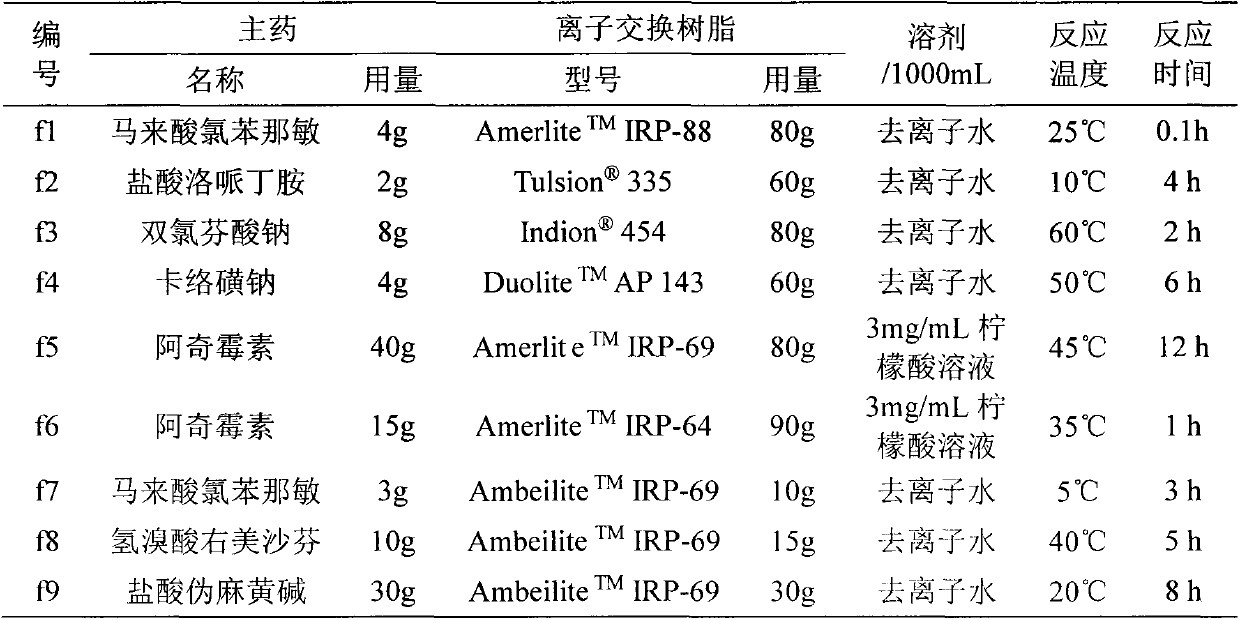

[0029] The preparation process of the drug-ion exchange resin complex is as follows: dissolve a certain amount of drug in 1000mL of the corresponding solvent, then add a certain amount of ion exchange resin, react at the corresponding temperature for a certain period of time, filter, and wash the product with deionized water , and dry to obtain the drug-ion exchange resin complex. See Table 1 for the dosage and conditions for the preparation of the corresponding compounds of each label.

[0030] Table 1 Conditions for the preparation of drug-ion exchange resin complexes

[0031]

Embodiment 2

[0032] Embodiment 2: Modification of drug-ion exchange resin complex

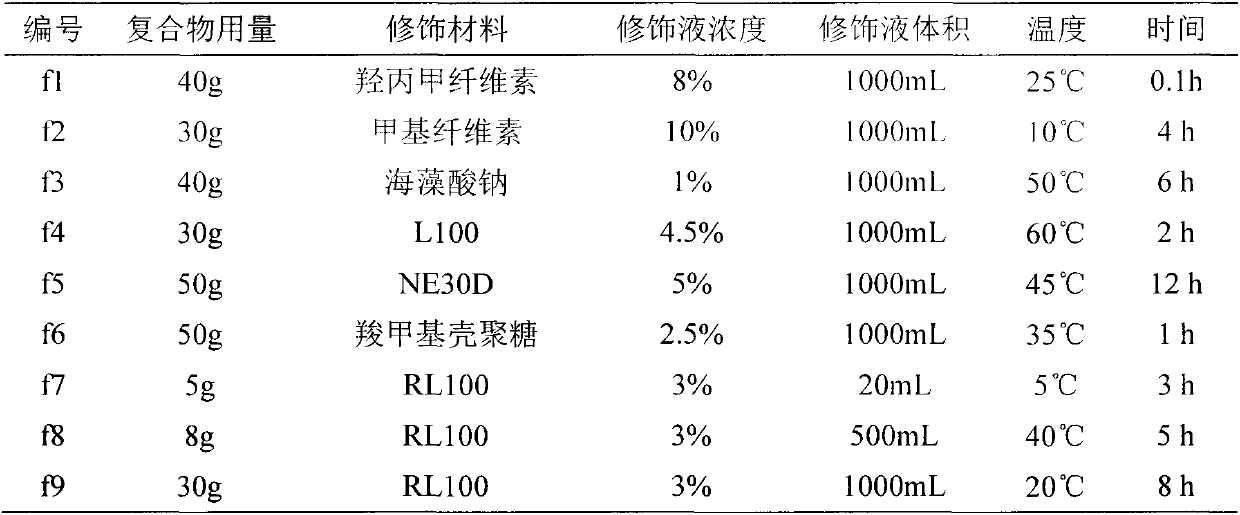

[0033] The modification process of the drug-ion exchange resin compound is as follows: the modification material is dissolved in water or swelled in water to obtain a modification material solution, and then the drug-ion exchange resin compound of each number in Example 1 is added to the modification material solution and stirred, filtered , washing the product, and drying to obtain the modified drug-ion exchange resin complex. The complex modification conditions corresponding to each label are shown in Table 2.

[0034] Table 2 Modification conditions of drug-ion exchange resin complexes

[0035]

Embodiment 3

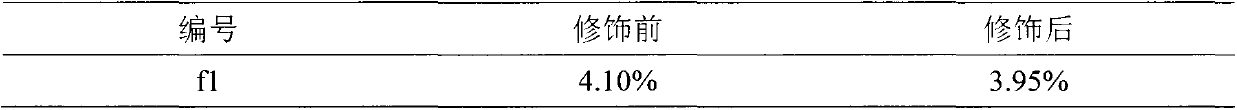

[0036] Example 3: Drug loading before and after modification of the drug-ion exchange resin complex

[0037] The drug-loading capacity of each drug-ion exchange resin complex before and after modification was measured by dissociation method, and the measured results are shown in Table 3 below.

[0038] Table 3 Drug loading of drug-ion exchange resin complexes before and after modification

[0039]

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com