Composition with diesel antiwear properties and diesel composition and their preparation method

A composition and performance technology, applied in biofuels, hydrocarbon oil treatment, petroleum industry, etc., can solve problems affecting product use and cumbersome steps, and achieve the effects of improving lubricity, easy availability of raw materials, and small average coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] The source of the raw material can be vegetable oil, or tall oil fatty acid recovered from animal oil or papermaking waste liquid. In order to achieve the above-mentioned fatty acid composition, the crude fatty acid is generally refined first. The refining methods include rectification, film Evaporation, molecular distillation and other distillation methods remove impurities and unsaponifiable matter, and methods such as urea inclusion, solvent low-temperature freezing filtration, and pressure filtration can also be used to reduce the content of saturated fatty acids. According to a preferred embodiment of the present invention, the raw material is obtained from biodiesel through rectification, saponification and acidification.

[0040] In step (1), the esterification reaction can utilize conventional esterification methods, such as adding a catalyst or performing the reaction at high temperature without a catalyst. The catalyst can be an acid catalyst, a base catalyst ...

Embodiment 1

[0056] (1) Esterification reaction

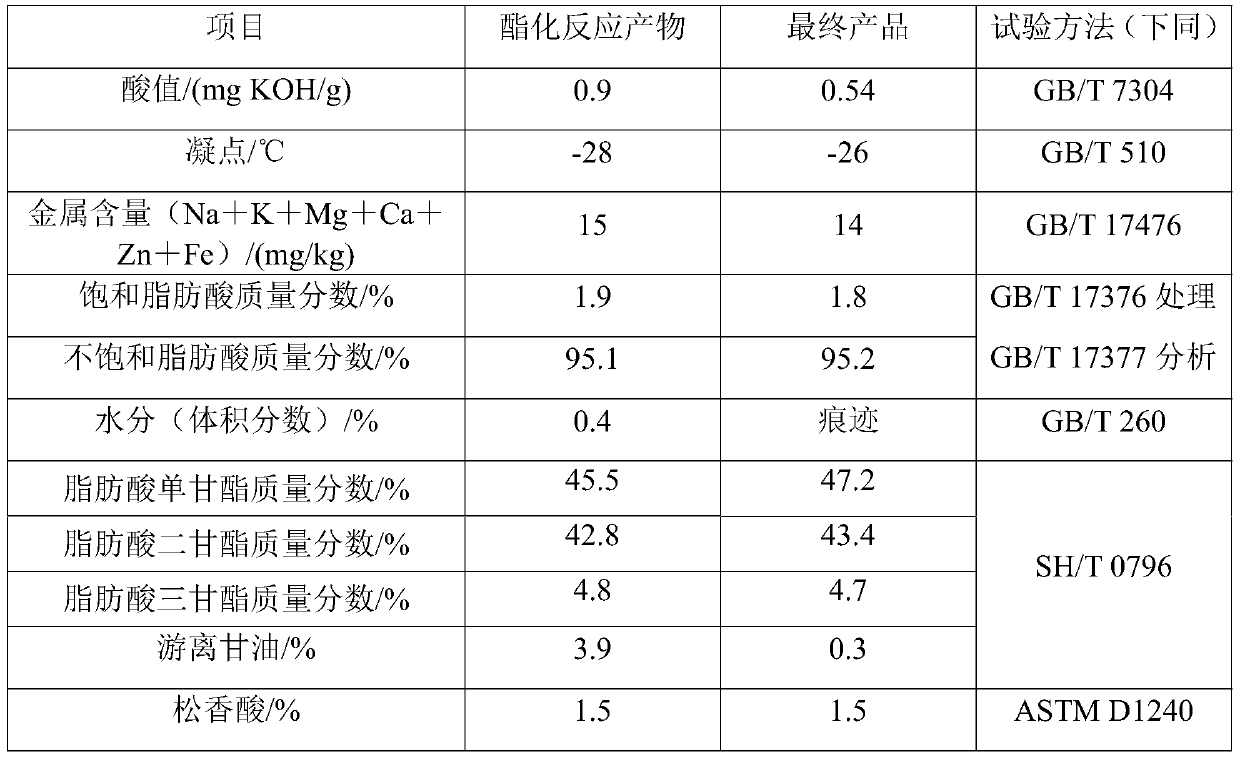

[0057] 500g of tall oil fatty acid (Arizonal company brand is 2LT product, cloud point-10 ℃) and 179.8g of glycerol are placed in a reactor equipped with electric stirrer, thermometer, reflux condenser, reflux water separator, heated and stirred The temperature was raised to 190°C, and the water generated by the reaction was carried out by purging with nitrogen and condensed into the water separator. After 10 hours of reaction, 27.6 g of water was separated, and 638.9 g of the reaction product was collected. The analysis results are shown in Table 2;

[0058] (2) Molecular distillation

[0059] 300 g of the reaction product from the previous step was subjected to a molecular distillation with a VKL70-5FDRR full-heating full-gear pump molecular distillation device of the German VTA company, with a controlled temperature of 145 ° C and an absolute pressure of 1.0 Pa. 278 g of the molecular distillation heavy fraction was collected as the fin...

Embodiment 2

[0063] (1) Esterification reaction

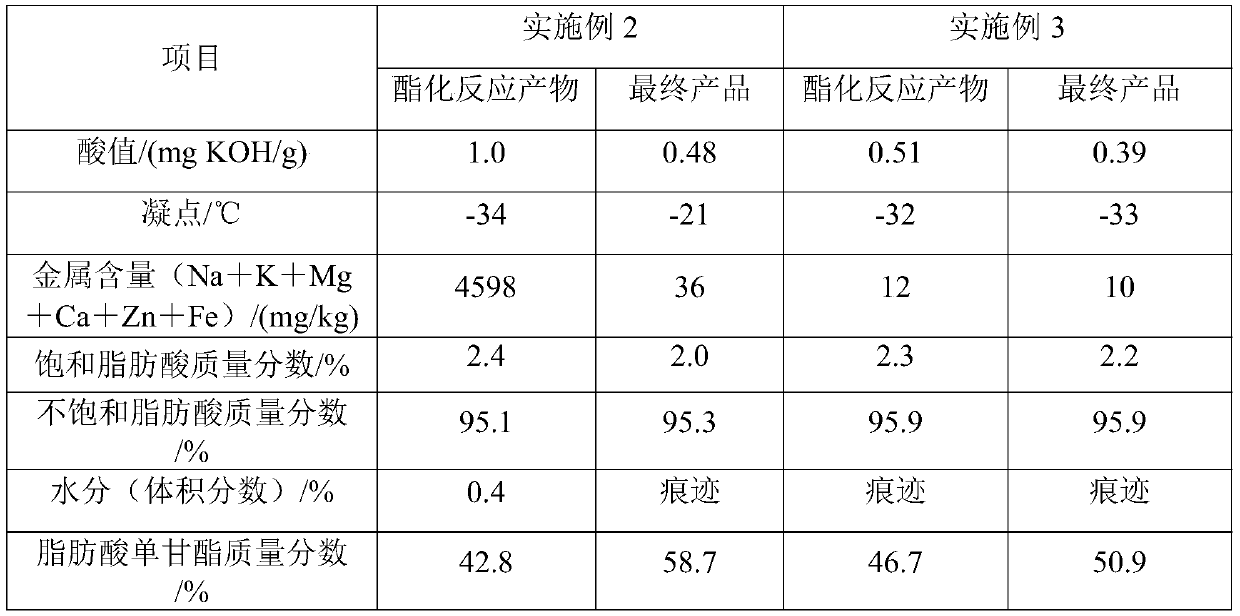

[0064] The NaOH of 500g refined cottonseed oil fatty acid (cloud point-13 ℃), 167.2g glycerol and 5.3g is placed in the reactor that an electric stirrer, thermometer, reflux condenser, reflux water separator are housed, and heating and stirring are heated up to At 160°C, purging with nitrogen gas carried out the water generated by the reaction and condensed it into the water separator. After 8 hours of reaction, 25.9 g of water was separated, and 626.7 g of the reaction product was collected. The analysis results are shown in Table 3;

[0065] (2) Molecular distillation

[0066] 300 g of the reaction product from the previous step was subjected to primary molecular distillation (temperature 146° C., absolute pressure 2.0 Pa) with a VKL70-5FDRR full-heating full-gear pump molecular distillation device from VTA, Germany. The heavy component from the primary molecular distillation was subjected to secondary molecular distillation (temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com