Production process of electronic ultra-thin glass

A technology of ultra-thin glass and production process, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., to achieve the effect of simplifying component design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

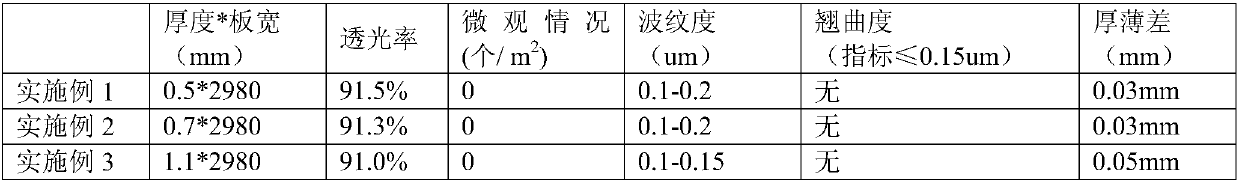

Embodiment 1

[0027] On the basis of ordinary glass components, the Si content is adjusted to be controlled at 72.5%, and the Al content is increased to 1.0% on the basis of ordinary glass components. 0.0095% of praseodymium oxide, 0.0098% of tantalum oxide and 0.0085% of neodymium oxide are added to the total mass of ordinary glass raw materials.

[0028] The electronic glass batch material is made of silica sand and the iron content is controlled at 400ppm to ensure that the light transmittance of electronic ultra-thin glass products is above 90%; the silica sand particle size of 24 mesh can be fully passed, and the ultrafine powder of 150 mesh can be controlled within 5%.

[0029] The particle size of dolomite and limestone is required to be controlled and there are no pollutants such as soil; the temperature of the material is controlled at 38°C to prevent the agglomeration of soda ash and Glauber's salt in the batch material from entering the melting section due to too low or too high t...

Embodiment 2

[0036] On the basis of ordinary glass components, the Si content is adjusted to be controlled at 73%, and the Al content is increased to 1.2% on the basis of ordinary glass components. 0.03% of praseodymium oxide, 0.05% of tantalum oxide and 0.01% of neodymium oxide are added to the total mass of ordinary glass raw materials.

[0037] The electronic glass batch material is made of silica sand and the iron content is controlled at 400ppm to ensure that the light transmittance of electronic ultra-thin glass products is above 90%; the silica sand particle size of 24 mesh can be fully passed, and the ultrafine powder of 150 mesh can be controlled within 5%.

[0038] The particle size of dolomite and limestone is required to be controlled and there are no pollutants such as soil; the temperature of the material is controlled at 40°C to prevent the agglomeration of soda ash and Glauber's salt in the batch material from entering the melting section due to too low or too high temperatu...

Embodiment 3

[0045] On the basis of ordinary glass components, the Si content is adjusted to be controlled at 72.5%, and the Al content is increased to 1.1% on the basis of ordinary glass components. 0.002% of praseodymium oxide, 0.003% of tantalum oxide and 0.001% of neodymium oxide are added to the total mass of ordinary glass raw materials.

[0046] The electronic glass batch material is made of silica sand and the iron content is controlled at 450ppm to ensure that the light transmittance of electronic ultra-thin glass products is above 90%; the particle size of silica sand is 24 mesh to achieve full pass, and the ultrafine powder of 150 mesh is controlled within 5%.

[0047] The particle size of dolomite and limestone is required to be controlled and there are no pollutants such as soil; the temperature of the material is controlled at 45°C to prevent the agglomeration of soda ash and Glauber's salt in the batch material from entering the melting section due to too low or too high temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com