Method for manufacturing a shoe with an air pumping device configured with an air box in the midsole

A technology of air pumps and bellows, applied in the field of shoe manufacturing, to achieve the effects of simplified component design, easy manufacture, and simplified control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

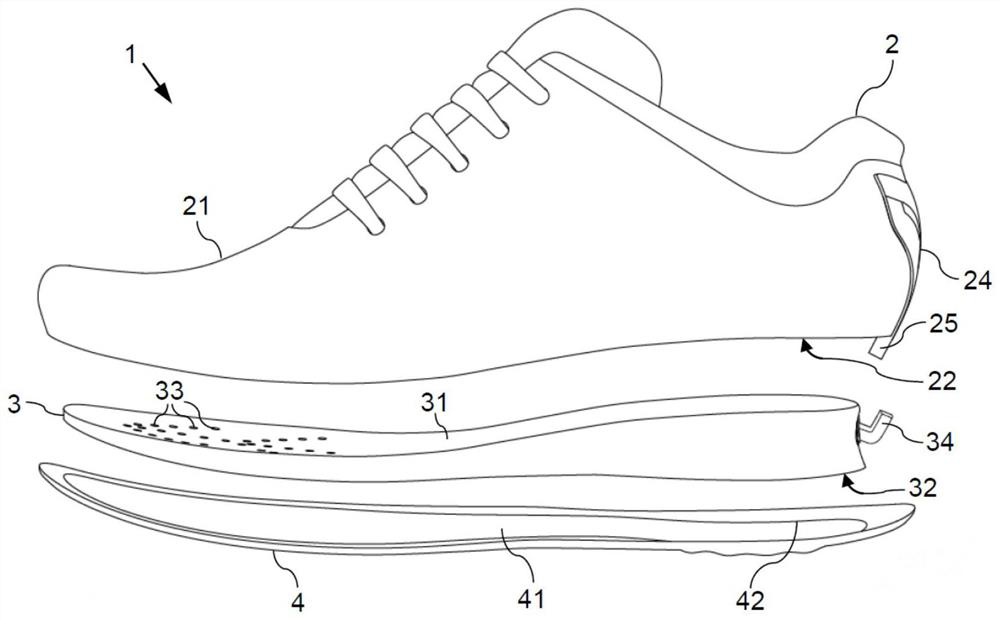

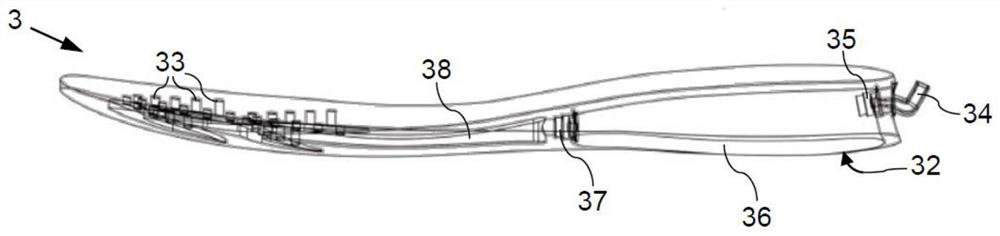

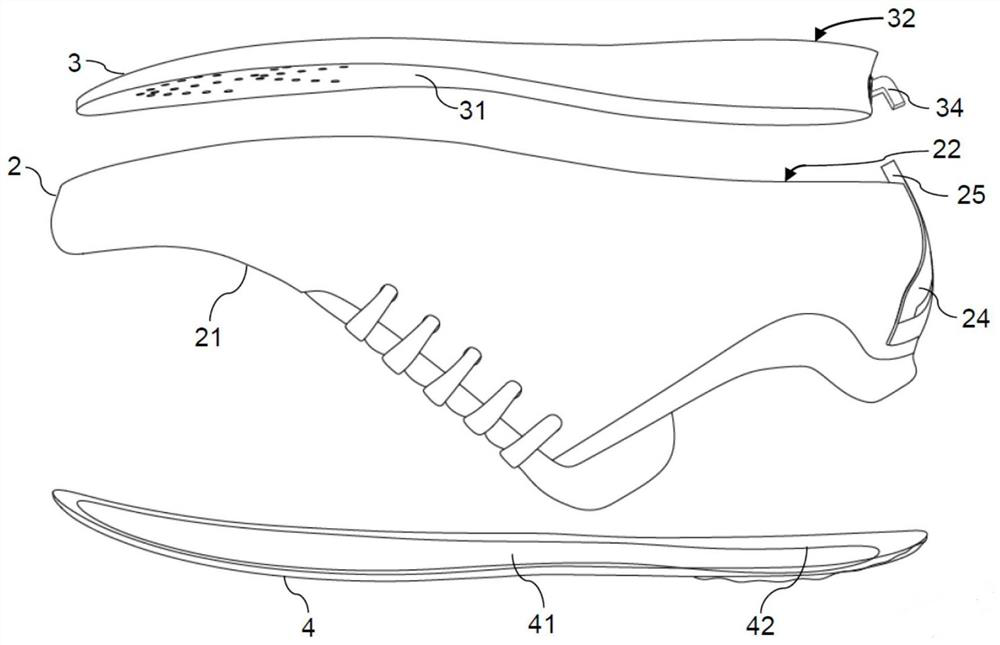

[0038] Now refer to Figures 1 to 4B A first embodiment of the method according to the invention for producing a shoe with an air pumping device arranged in the heel region is described.

[0039] figure 1 A schematic side view is shown of the three basic components used to manufacture the shoe 1 , namely the upper 2 , the midsole 3 and the outsole 4 .

[0040] The upper 2 includes an upper material portion 21 and a sole portion 22 . In this context, sole portion 22 shall refer to the ground-facing portion of the upper and to which the sole structure described below is attached. The upper material portion 21 is the rest of the upper 2 . Sole portion 22 generally includes an insole and may also include additional layers of the shoe, such as an inset sole. In some embodiments, a separate insole can also be dispensed with, eg the leather of the upper can surround the foot starting from the upper material part, eg in the case of eg moccasins.

[0041] The midsole 3 is preferab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com